Soil mixing machine

A soil and frame technology, applied in agricultural machinery and implements, shovels, plows, etc., can solve the problems of unevenness, inability to mix fertile soil evenly, and inability to supply uniform fertilizers, etc., and achieve the effect of high comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

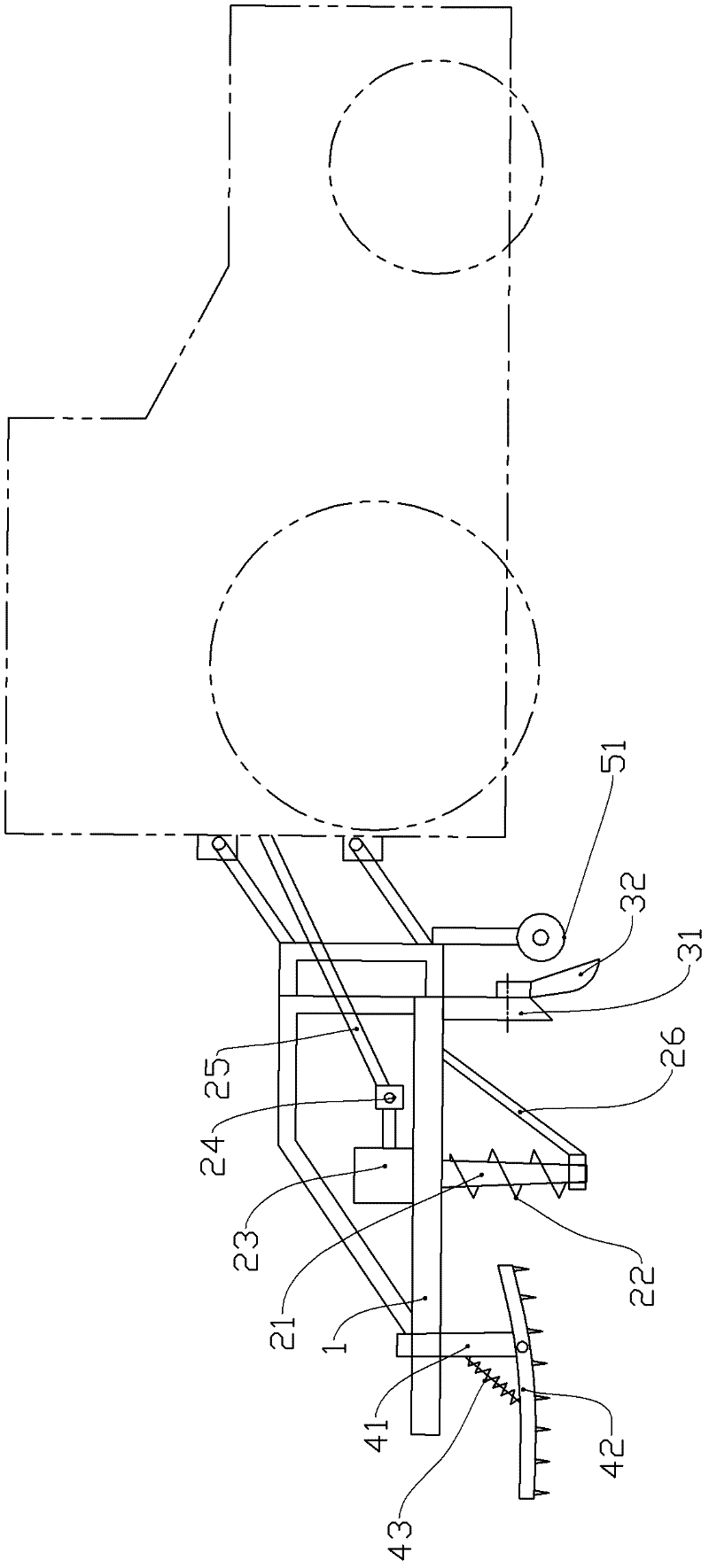

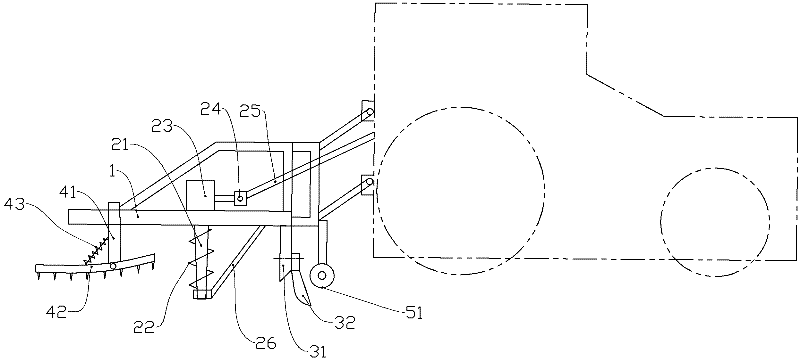

[0016] like figure 1 , figure 2 As shown, a soil homogenizer includes a frame, a plow part, a rotary tiller part, a harrow part and a ground wheel. The frame 1 is an installation platform, and the frame is connected with the tractor simultaneously. The plow part is the main part of the plowing operation, the rotary plowing part is the main part of the rotary plowing operation, the harrow part is the main part of the harrowing operation, and the ground wheel is used to support the frame to ensure the depth of plowing and the stability of the plowing process .

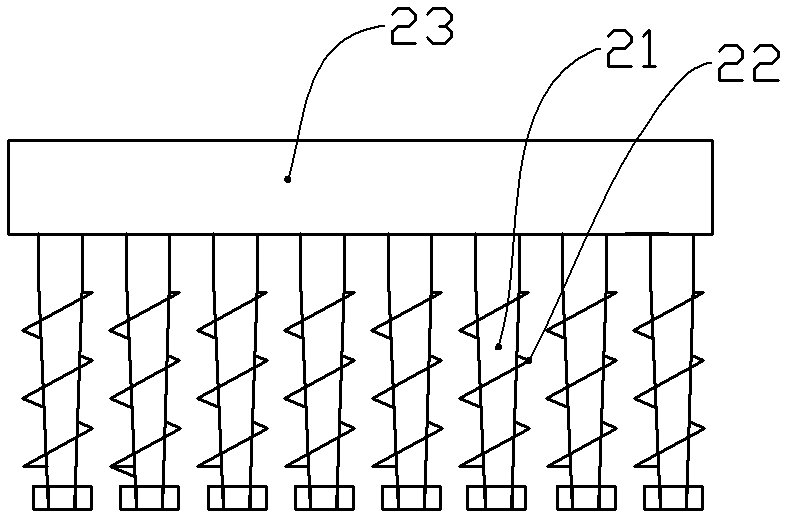

[0017] The rotary tillage section is installed in the middle of the frame, and the rotary tillage section includes a toothed screw 21, a gear box 23, a universal joint 24 and a main shaft 25, wherein the output shaft and the input shaft of the gearbox 23 are arranged at right angles and are bevel gears. Transmission, the interior of the gearbox is meshed by a bevel gear set. And the output shaft and the input shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com