Self-walking carrier

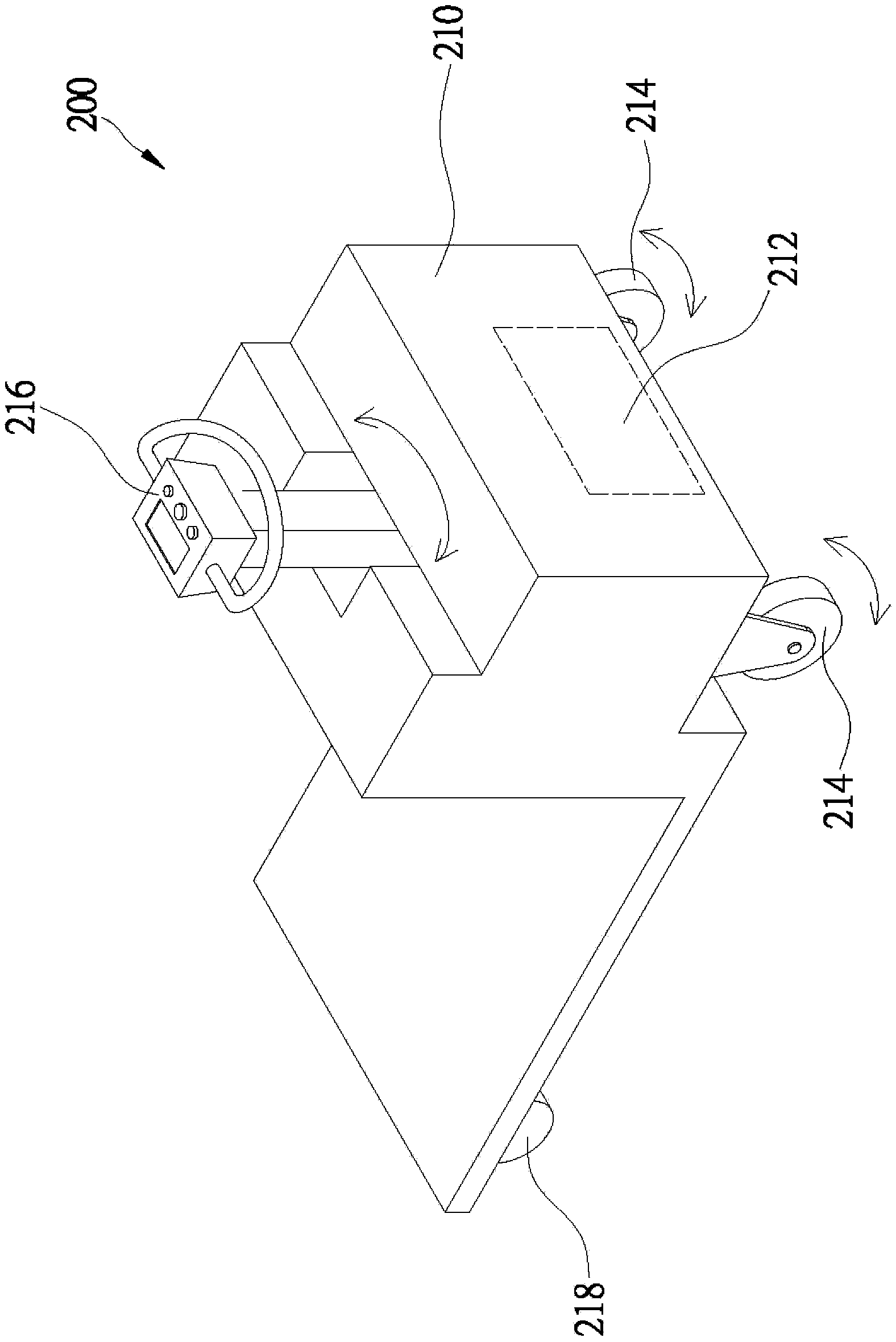

A self-propelled truck and self-propelled technology, which is applied in two-dimensional position/channel control, attitude control, etc., can solve problems such as the tilt of the vehicle body 210, imperfect self-propelled truck 200, and deviation of the driving path, so as to avoid vehicle Body flipping, manipulation and application of flexible and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

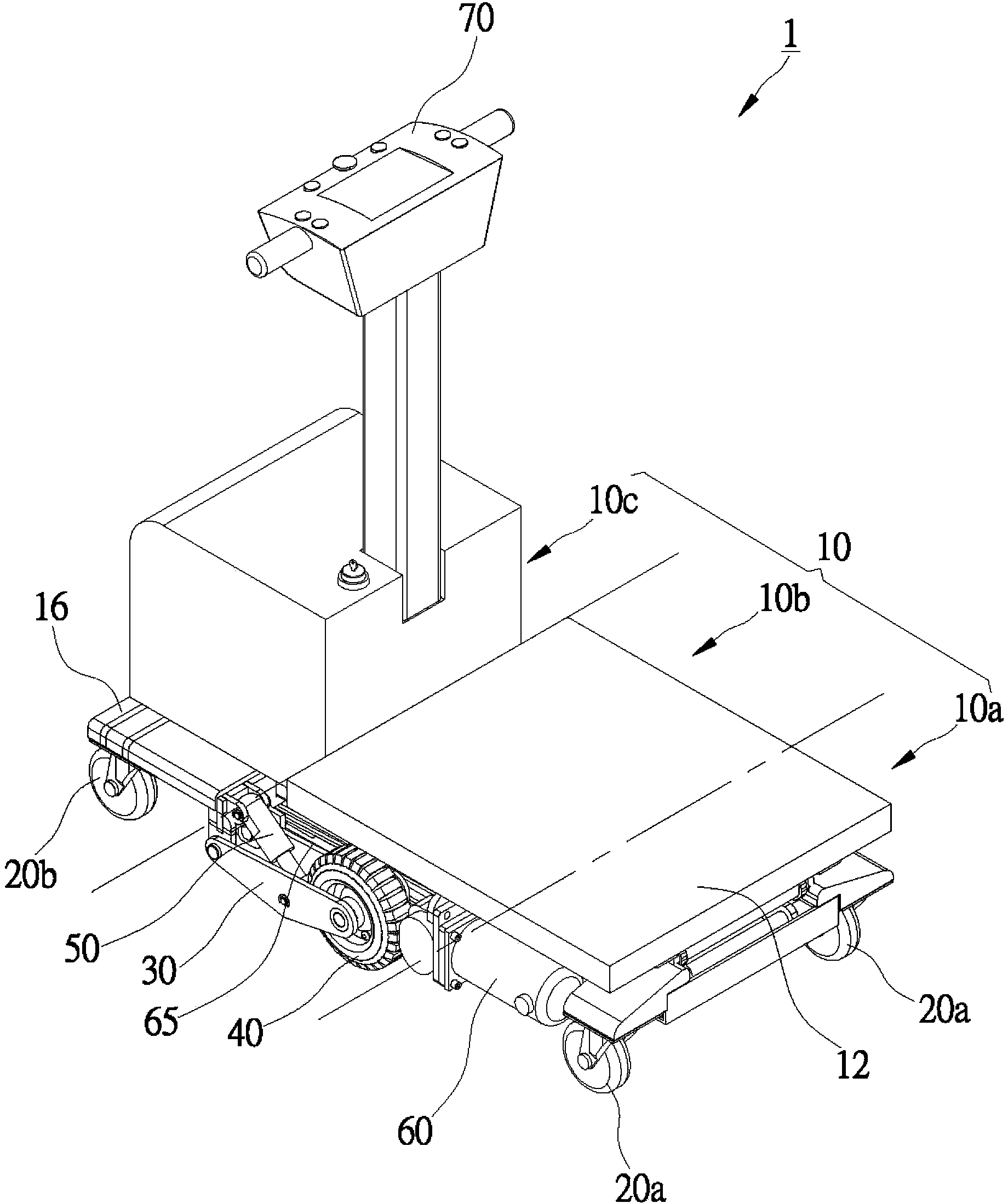

[0034] The self-propelled transport vehicle provided by the present invention includes a vehicle body, at least two auxiliary wheels, two power wheels, two connecting mechanisms, two motors and a control device. Wherein, the vehicle body is sequentially divided into a front section, a middle section and a rear section according to the direction of travel, and has a bearing part for carrying objects; the at least two auxiliary wheels are respectively arranged on the front section and the rear section of the vehicle body. Rear segment; the wheel surfaces of the two power wheels are attached to the ground; the two connecting mechanisms respectively connect the two power wheels and the vehicle body, so that the two power wheels are located at the middle section of the vehicle body, and each The power wheels can reciprocate close to or away from the vehicle body according to a predetermined path; the two motors are arranged on the vehicle body to drive and rotate the power wheels re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com