Method for lifting fluid and device

A lifting device, liquid technology, applied in the direction of machine/engine, non-displacement pump, mechanical equipment, etc., to achieve the effect of saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

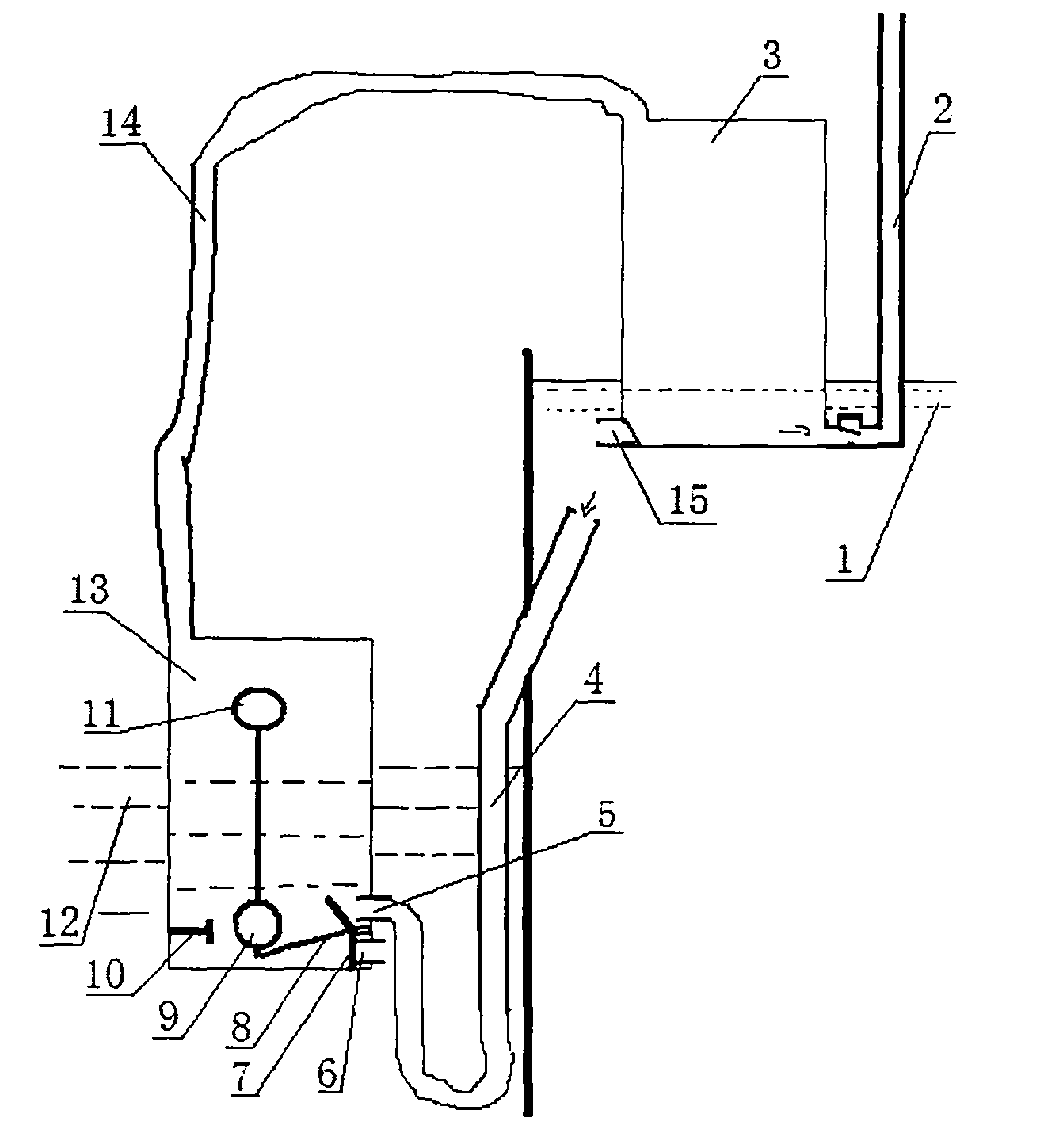

[0019] The implementation is as figure 1 As shown, the liquid lifting device of the present invention includes a liquid pressure feeding mechanism, and the liquid pressure feeding mechanism includes an air pipe 14, an upper container 3, and a lower container 13. The inner cavities of the upper container 3 and the lower container 13 are airtight liquid storage chambers. The top surface of the upper container 3 and the lower container 13 is connected, so that the liquid storage chambers of the upper container and the lower container are communicated. The position of the upper container 3 is higher than that of the lower container 13. The bottom of the upper container 3 is provided with a liquid inlet 15 and a liquid outlet. The bottom of the container 13 is provided with a liquid inlet 5 and a liquid outlet 6, and a one-way valve is installed on the liquid inlet and the liquid outlet of the upper container 3. The liquid outlet of the upper container 3 is connected to the high-le...

Embodiment approach 2

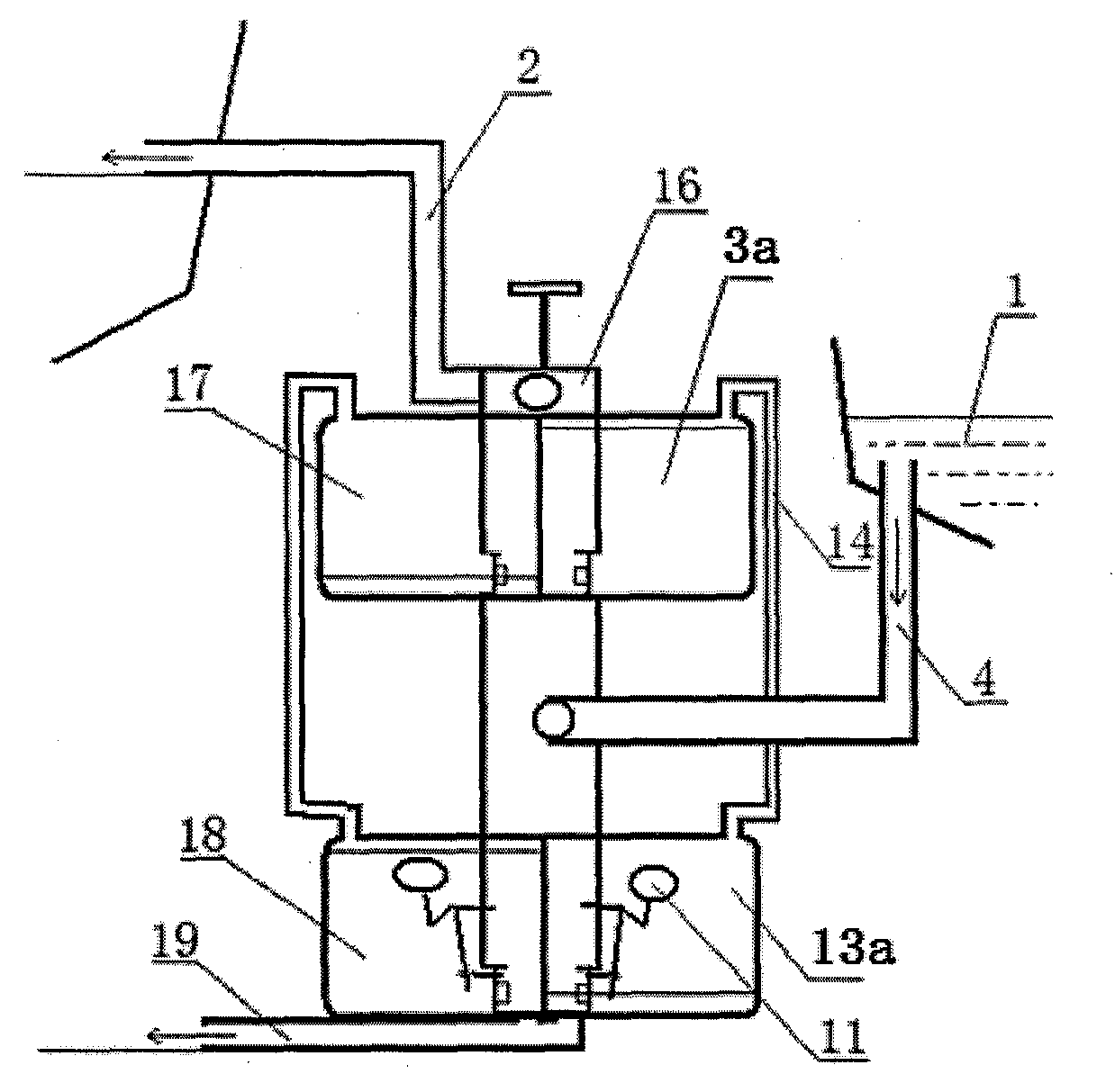

[0021] The second embodiment is as figure 2As shown, the liquid elevating device of the present invention adopts a parallel type, including a bracket 16 and parallel first and second two identical aforementioned liquid pressure feeding mechanisms, the first upper container 3a, the first lower pressure feeding mechanism of the first liquid pressure feeding mechanism The second upper container 17 and the second lower container 18 of the container 13a and the second liquid pressure feeding mechanism are all installed on the support 16, and the liquid outlets of the first upper container 3a and the second upper container 17 are connected with the same high-level output port. The pipe 2 is connected, the liquid outlets of the first lower container 13a and the second lower container 18 are connected with the same low output pipe 19; the first upper container 3a, the second upper container 17, the first lower container 13a, and the second lower container 18 The liquid inlet is conne...

Embodiment approach 3

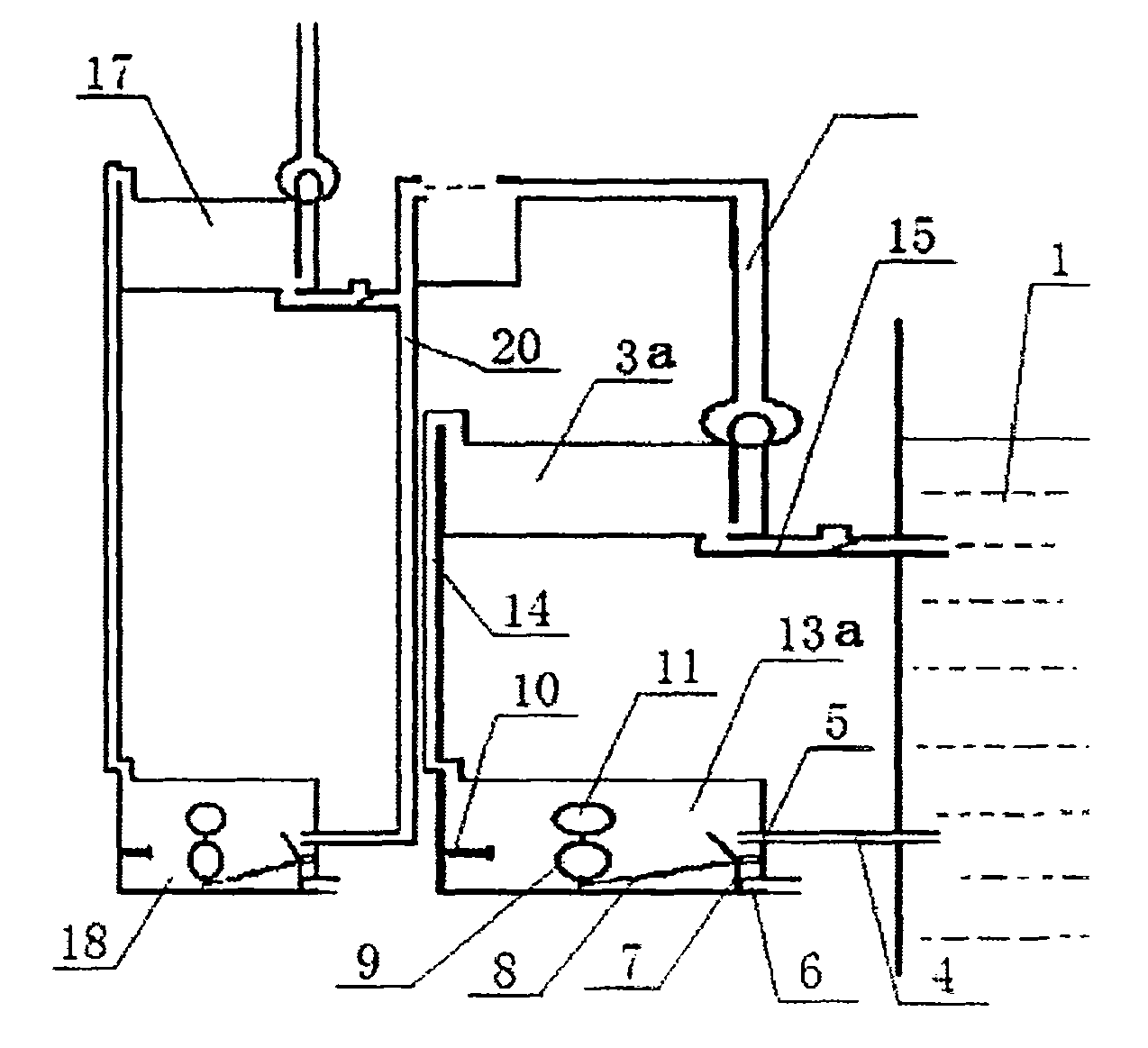

[0022] Three ways to implement image 3 As shown, the liquid lifting device of the present invention adopts a series type, including the first and second two identical aforementioned liquid pressure-feeding mechanisms, the first liquid pressure-feeding mechanism and the second liquid pressure-feeding mechanism are connected in series, which can increase the liquid lifting height, The high-level output pipe 2 of the first liquid pressure-feeding mechanism is connected with the input pipe 20 of the second liquid pressure-feeding mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com