Microalgae culturing device and microalgae culturing method

A technology of microalgae cultivation and culture solution, applied in the direction of microorganism-based methods, enzymology/microbiology devices, biochemical cleaning devices, etc., can solve the problems of difficult engineering and short photosynthesis time, and achieve gas-liquid mass transfer The effect of improved driving force, energy saving, and easy amplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

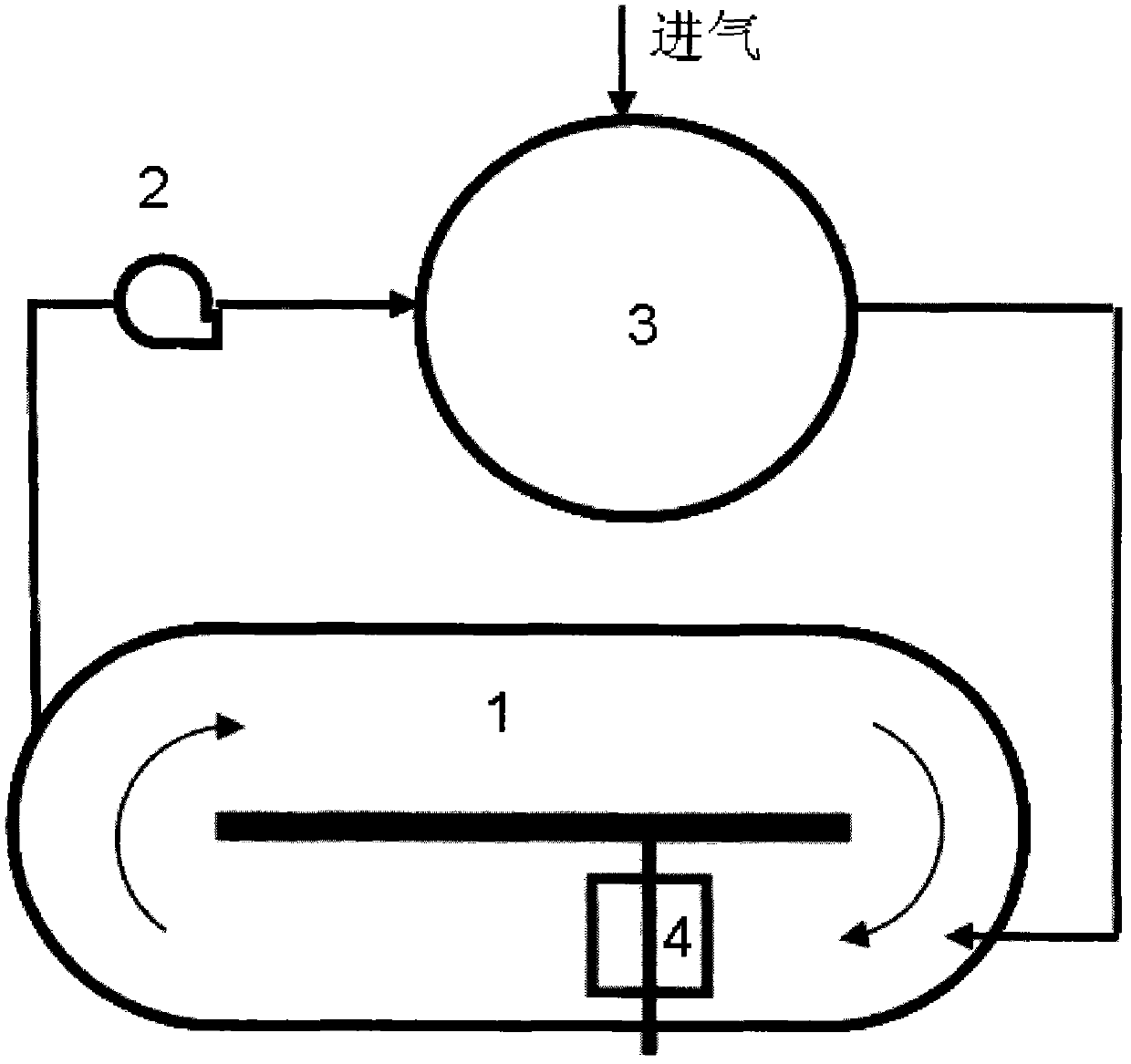

[0035] Two ellipse-shaped open track pools (6.44 square meters of culture area) with a length of 3.8 meters and a width of 1.9 meters were used to cultivate Nanochloropsis outdoors for comparison and illustration.

[0036] One of the runway pools has a liquid filling height of 0.05m (total volume 360 liters), and one side of it is connected to a liquid circulation pump through a pipeline. , the bottom of the cylindrical storage tank with a liquid capacity of 3.6 cubic meters, and the bottom of the culture solution storage tank is fed with air / CO 2 Mixed gas (5% CO 2 , v / v), the ventilation volume is 0.3VVM, and the gauge pressure of the storage tank is maintained at 1kg / cm 2 . From the top of the culture liquid storage tank, the culture liquid flows into the other side of the open runway pool through the pipeline. Control the flow rate of the water pump to 10 cubic meters per hour to keep the average residence time of the culture solution in the raceway pool at 120 second...

Embodiment 2

[0040] Two elliptical open track pools with a length of 3.8 meters and a width of 1.9 meters are used for outdoor cultivation of Nanochloropsis. One of the open runway pools has a liquid filling height of 0.05m (total volume 360 liters), and one side of it is connected with a liquid circulation pump through a pipeline. 2.5 meters, the bottom of the cylindrical storage tank with a liquid capacity of 1.1 cubic meters, and the bottom of the culture solution storage tank is fed with air / CO 2 Mixed gas (5% CO 2 , v / v), the ventilation volume is 0.3VVM, and the gauge pressure of the storage tank is maintained at 1kg / cm 2 . From the top of the culture liquid storage tank, the culture liquid flows into the other side of the open runway pool through the pipeline. Control the flow rate of the water pump to 20 cubic meters per hour to keep the average residence time of the culture solution in the raceway pool at 60 seconds. Stop the circulation at night, and pump all the culture fl...

Embodiment 3

[0044] Two elliptical open track pools with a length of 3.8 meters and a width of 1.9 meters are used for outdoor cultivation of Nanochloropsis. One of the open runway pools has a liquid filling height of 0.05m (total volume 360 liters), and one side of it is connected with a liquid circulation pump through a pipeline. 2.5 meters, the bottom of the cylindrical storage tank with a liquid capacity of 1.1 cubic meters, and the bottom of the culture solution storage tank is fed with air / CO 2 Mixed gas (5% CO 2 , v / v), the ventilation volume is 0.3VVM, and the gauge pressure of the storage tank is maintained at 1.6kg / cm 2 . From the top of the culture liquid storage tank, the culture liquid flows into the other side of the open runway pool through the pipeline. Control the flow rate of the water pump to 20 cubic meters per hour to keep the average residence time of the culture solution in the raceway pool at 60 seconds. Stop the circulation at night, and pump all the culture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com