Cyclic operation control system of intelligent numerical control electromagnetic crane

A cyclic operation and control system technology, applied in the field of electromagnetic cranes and intelligent numerical control electromagnetic cranes, can solve problems such as misoperation, potential safety hazards, and low crane use efficiency, and achieve the goal of improving safety performance, improving operation control level, and improving efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

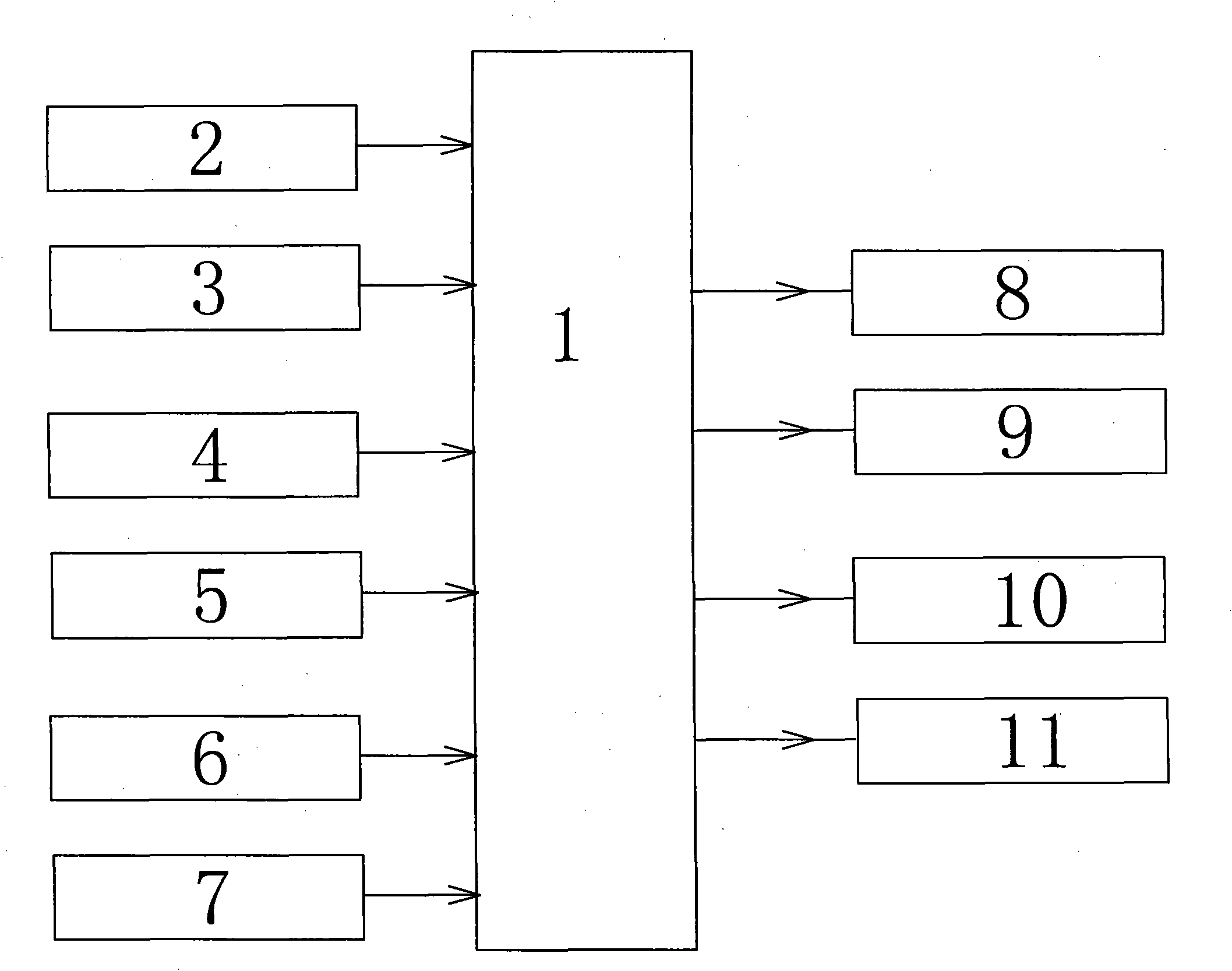

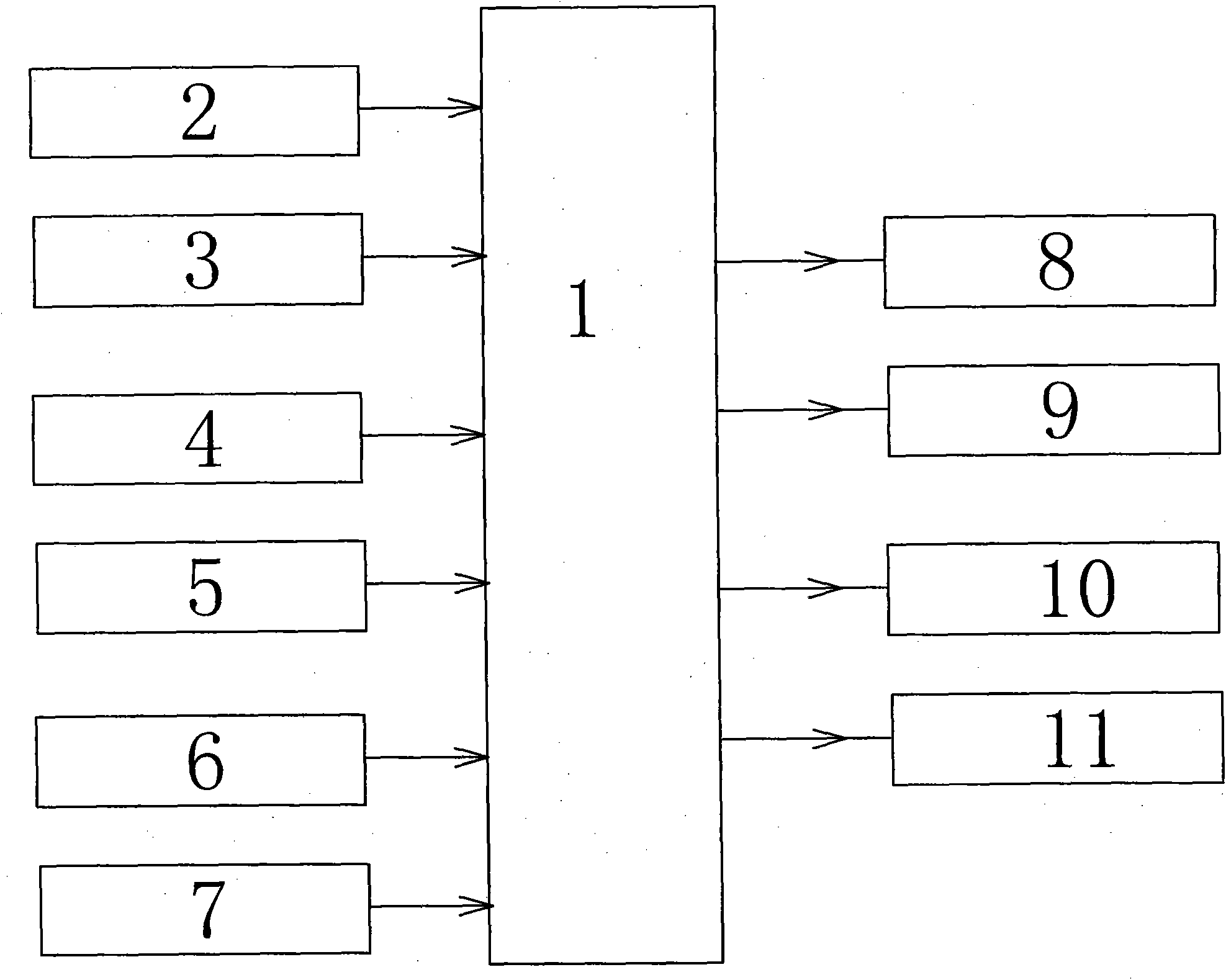

[0008] Such as figure 1 As shown, the present invention is provided with a control center 1, a cart position sensor 2, a cart position sensor sensor 3, a lifting height sensor 4, an electromagnetic chuck distance sensor 5, a position input device 6, a working cycle command input device 7, a cart Operation control device 8, trolley operation control device 9, electromagnetic chuck grabbing control device 10, and hanger lifting control device 11.

[0009] The signal input terminals of the cart position sensor 2, the trolley position sensor sensor 3, the lifting height sensor 4, the electromagnetic chuck distance sensor 5, the position input device 6 and the duty cycle command input device 7 are respectively connected to the control center 1.

[0010] The control signal output terminals of the control center 1 are respectively connected to the crane operation control device 8, the trolley operation control device 9, the electromagnetic chuck grasping control device 10, and the hanger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com