Obliquely overlapped paper cup and manufacturing method thereof

A technology of paper cups and overlapping edges, which is applied in the field of paper cup manufacturing, can solve the problems of large gaps, waste paper waste, and high production costs, and achieve the effects of reduced raw material costs, small equipment investment, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

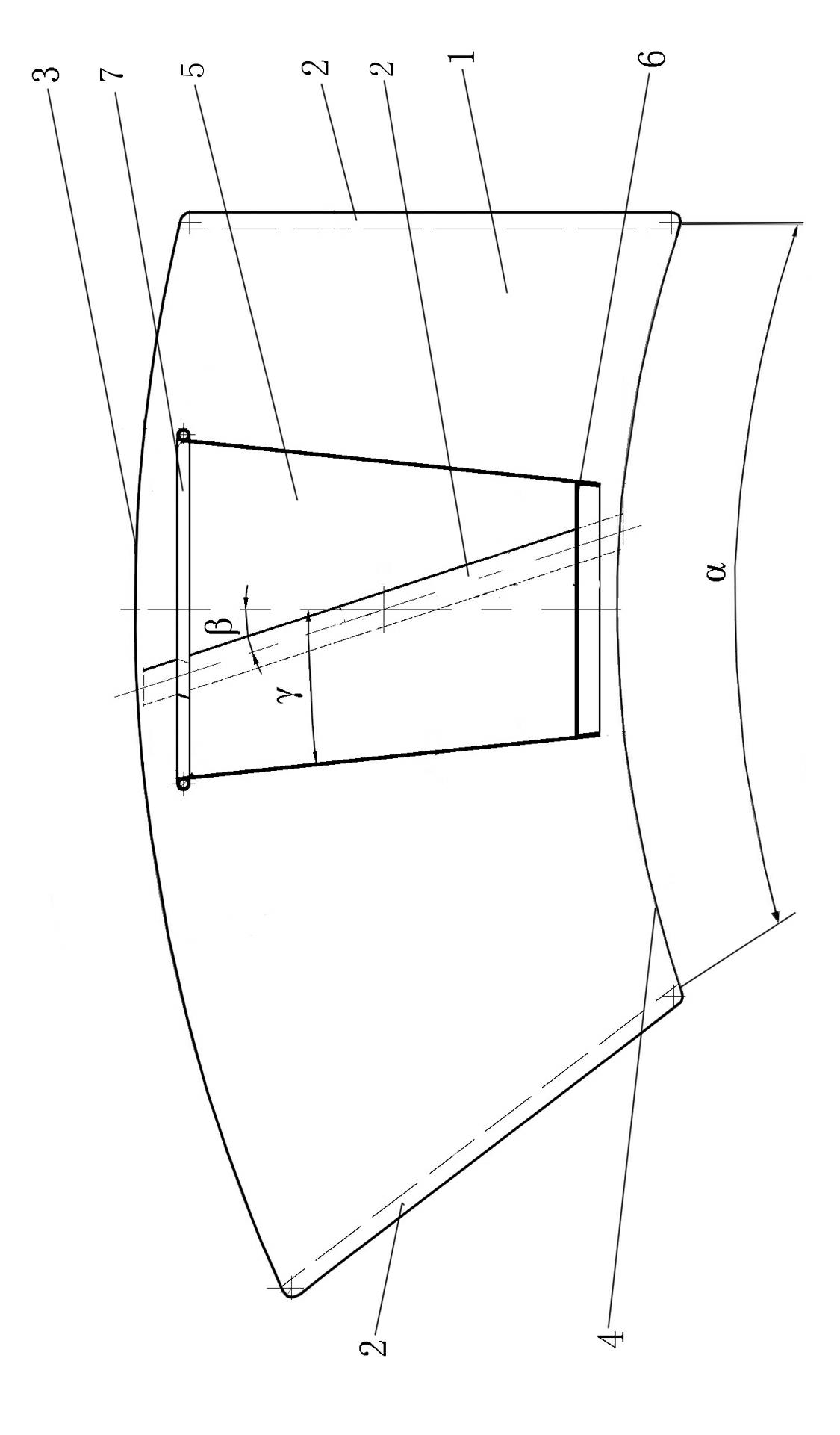

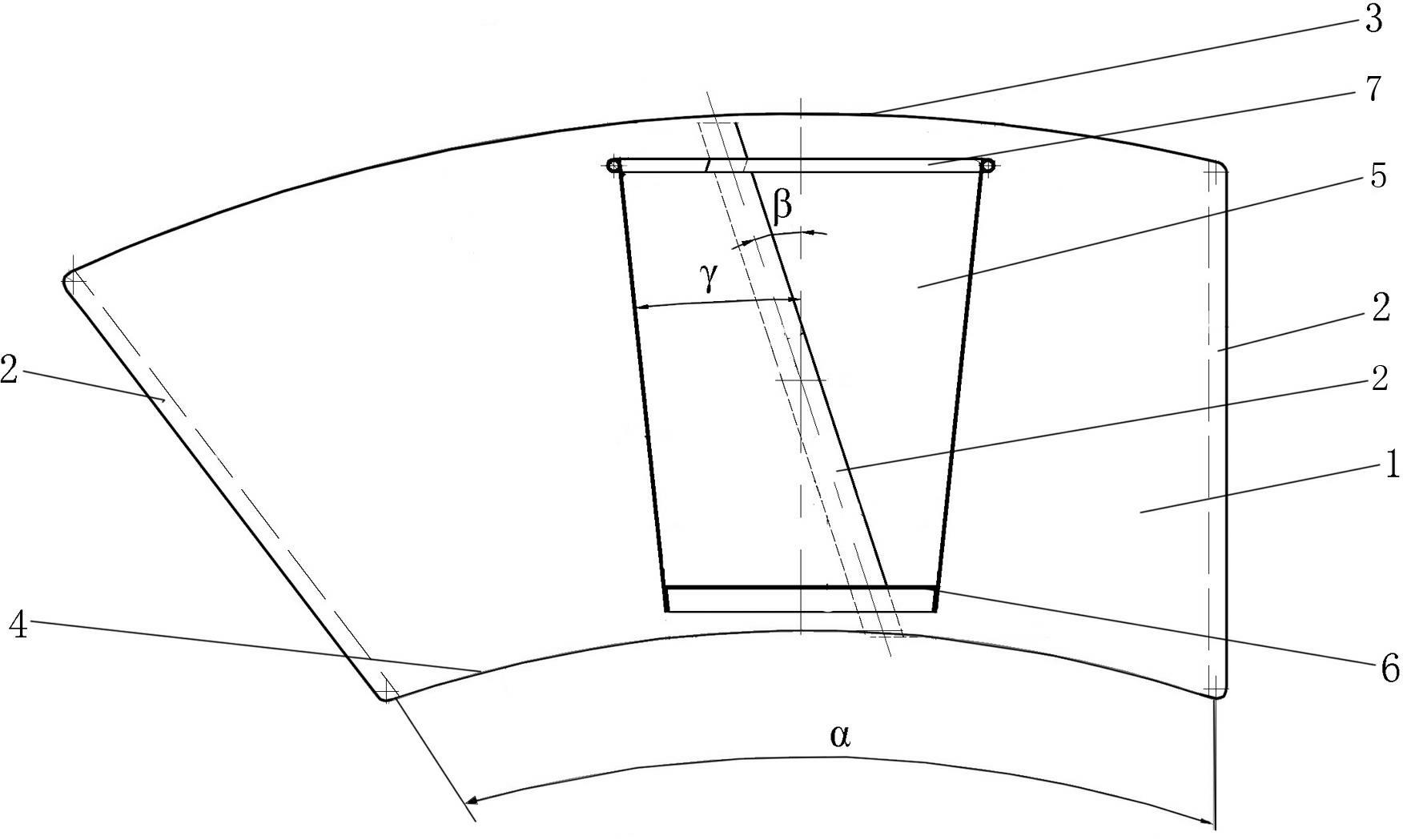

[0019] Embodiment: a kind of obliquely lapped paper cup of this example, as figure 1 , there is an unfolded paper tape body 1, and the left and right ends of the paper tape body are respectively provided with an overlapping edge 2, the right overlapping edge is arranged vertically, the left overlapping edge is arranged obliquely, and the angle between the two overlapping edges α is 32o, the upper and lower edges of the tape body 1 are the upper arc edge 3 and the lower arc edge 4 respectively, wherein the radius of the upper arc edge is 474.6mm, the arc length is 275.84mm, and the radius of the lower arc edge is 345.39mm mm, the arc length is 203.03mm. The left and right ends of the paper tape body are rolled inwardly to form a frustum-shaped cup body 5, and the taper angle γ of the outer surface of the cup body is 10°. The diameter of the upper end of the cup body is 91mm, and the diameter of the lower end is 63.5mm. The two overlapping edges are fixed together, and the ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com