Rotating electric machine, wind power generation system and method of manufacturing rotating electric machine

A technology for wind power generation systems and rotating electrical machines, applied to synchronous motors with stationary armatures and rotating magnets, wind power engines, wind power generation, etc., which can solve problems such as difficult assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

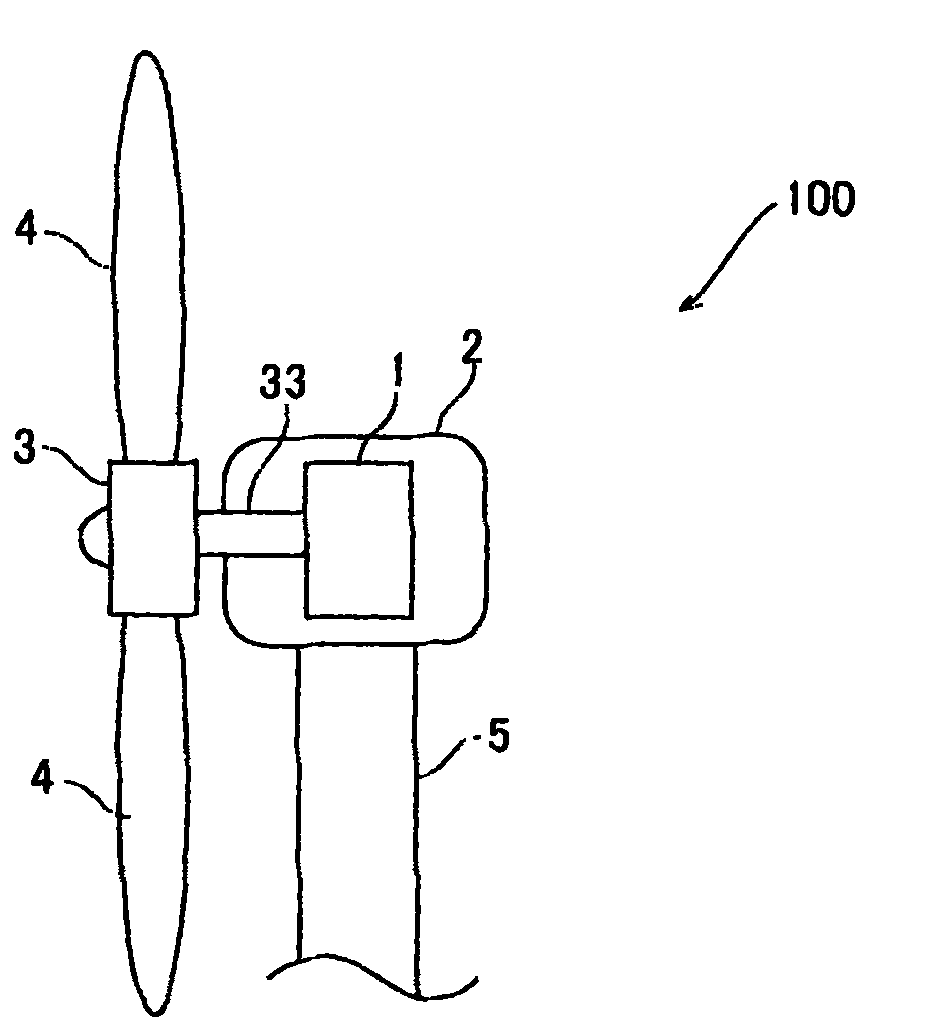

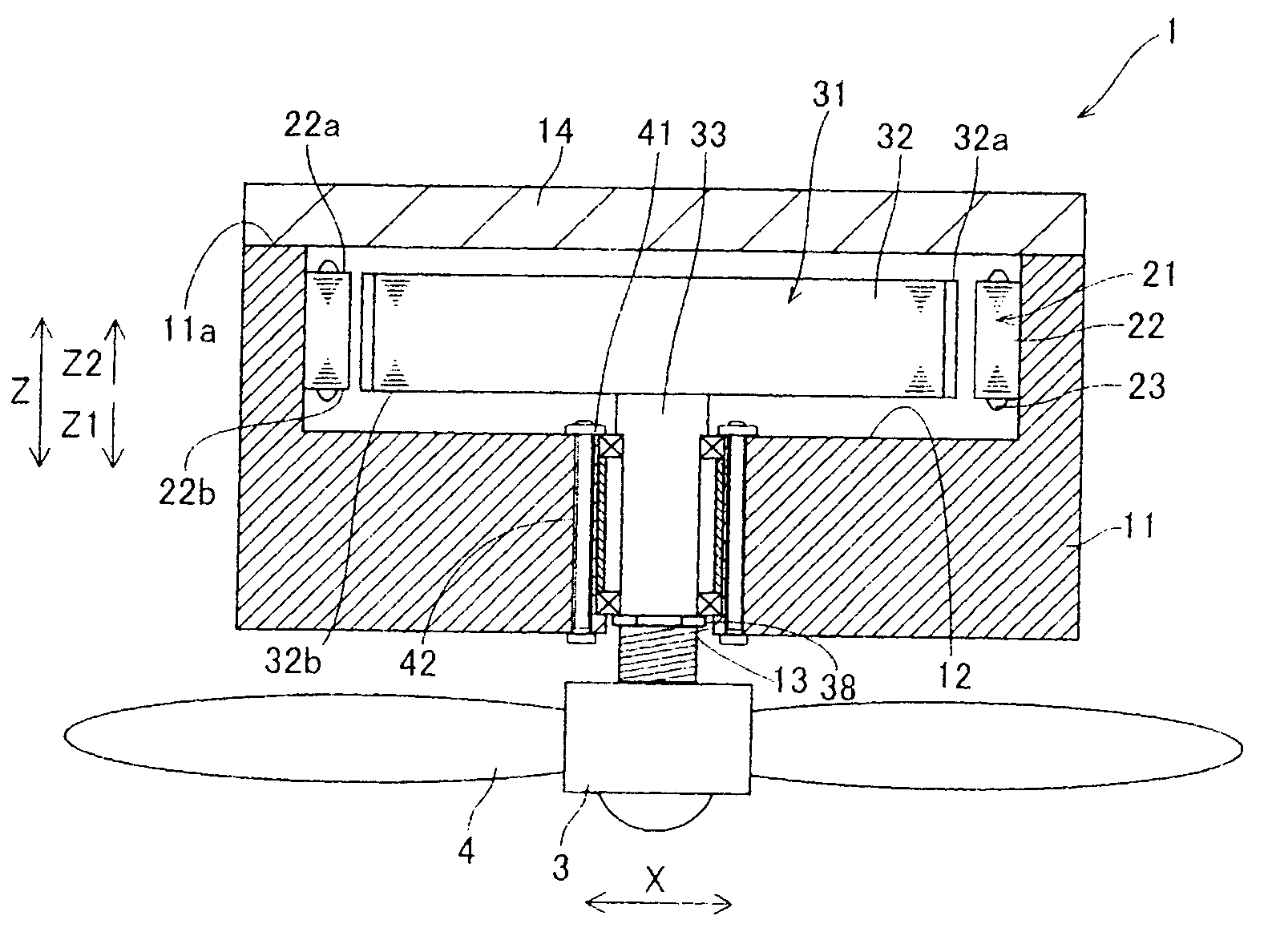

[0029] First, refer to Figure 1 to Figure 4 , the configuration of the wind power generation system 100 according to the first embodiment of the present invention will be described. In addition, in the first embodiment, an example in which the rotating electric machine of the present invention used in the wind power generation system 100 is used as the generator 1 will be described.

[0030] Such as figure 1As shown, the wind power generation system 100 is composed of a generator 1 , a nacelle 2 for accommodating the generator 1 , a rotor hub 3 , blades 4 and a tower 5 . The generator 1 is accommodated in the nacelle 2 . In addition, the rotor hub 3 is attached to a rotating shaft 33 described later of the generator 1 . In addition, a plurality of blades 4 are attached to the rotor hub 3 . Furthermore, the nacelle 2 is mounted on a tower (support column) 5 .

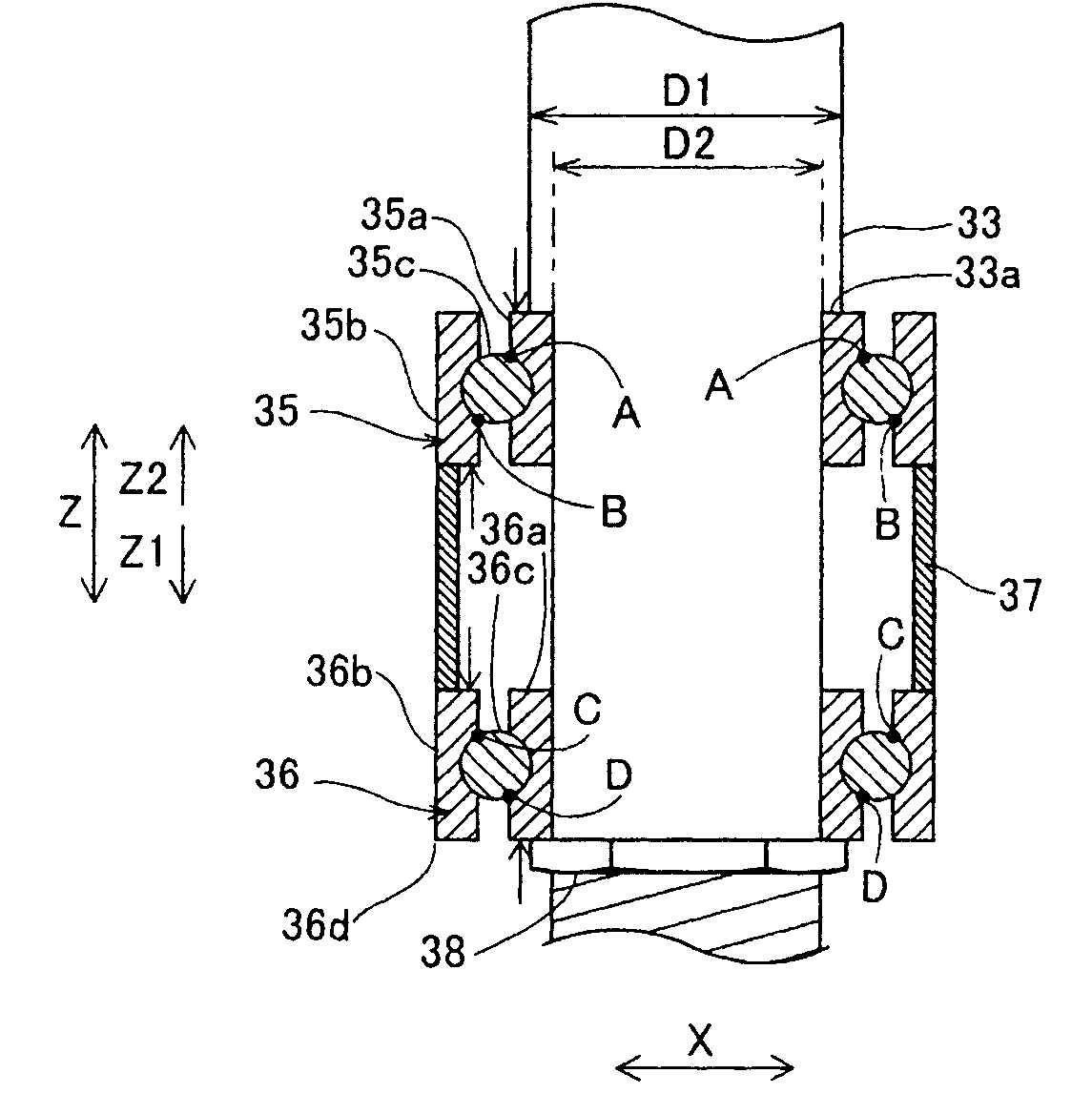

[0031] Such as Figure 4 As shown, the generator 1 is composed of a housing 11 , a stator 21 and a rotor 31 . ...

no. 2 approach

[0050] Below, refer to Figure 8 and Figure 9 , the generator 1a of the second embodiment will be described. Unlike the above-mentioned first embodiment in which the first ball bearing 35 and the second ball bearing 36 are attached to the rotating shaft 33 in advance, in this second embodiment, the first ball bearing 55 and the second ball bearing 56 are attached in advance. into the rotating shaft support hole 53. In addition, the overall structure of the wind power generation system of the second embodiment is the same as that of the above-mentioned first embodiment (refer to figure 1 )same.

[0051] Such as Figure 9 As shown, the generator 1 a of the second embodiment is composed of a casing 51 , a stator 61 and a rotor 71 . The housing 51 is formed in a cylindrical shape. In addition, the housing 51 is provided with a recessed portion 52 for accommodating the stator 61 and the rotor 71 . Further, a rotating shaft support hole 53 into which the rotating shaft 73 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com