Contact element and system comprising contact element and corresponding element

A contact element and plug-in system technology, applied in the direction of electrical elements, contacts, electrical connection of contacts, etc., can solve problems such as large withdrawal force and difficulty, and achieve the effect of reliable contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

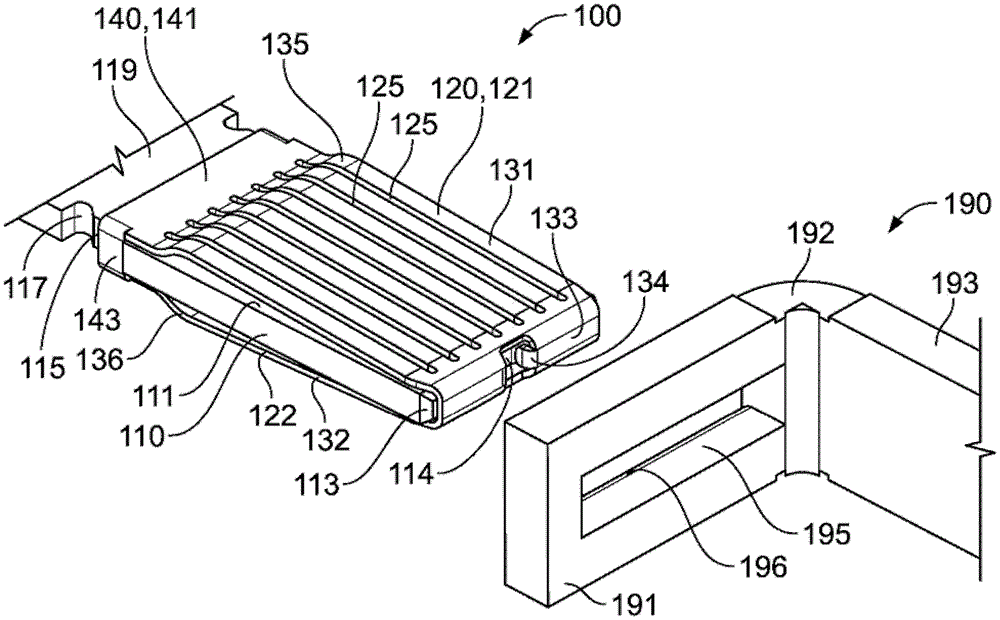

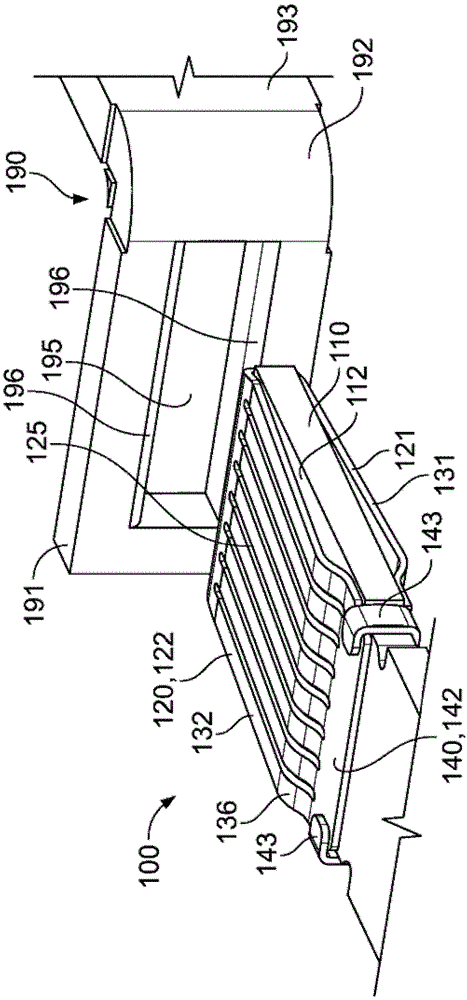

[0039] figure 1 with 2 as well as image 3 with 4 Different partial perspective views of the contact element 100 and the associated counter contact element 190 are shown in each case before and after producing the electrical plug connection. The corresponding transverse cross-sectional views of the two contact elements 100, 190 before and after the connecting operation are further shown in Figure 5 with 6 middle. Two contact elements 100, 190 made of electrically conductive or metallic material (eg copper alloy) which can be plugged together can be configured for high current-carrying capacities, therefore, especially in the case of motor circuit breakers of modular construction , for detachably electrically connecting the various components or modules of the motor circuit breaker together. Such use of contact elements 100, 190 will be combined below Figure 8-19 discussed in further detail. Refer below Figure 1-6 The description first concerns the details and feature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com