Internal combustion engine

An internal combustion engine and actuator technology, applied to engine components, machines/engines, mechanical equipment, etc., can solve the problems of complicated installation and limited flexibility, and achieve the effect of simplifying assembly, simplifying processing, and reducing structural tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

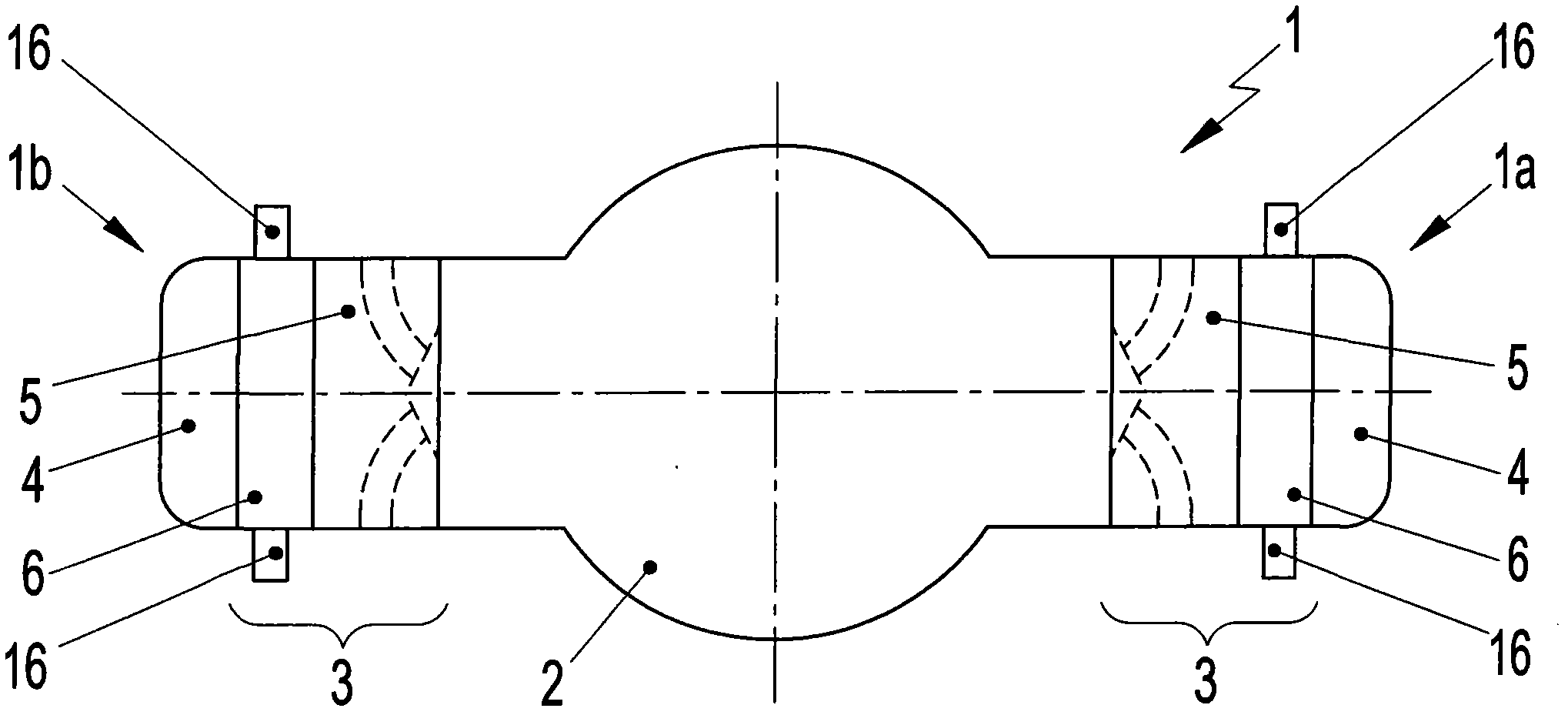

[0019] figure 1 Shown is an opposed-cylinder internal combustion engine 1 formed of two banks of cylinders 1a and 1b arranged horizontally. The internal combustion engine 1 comprises a crankcase 2 and a cylinder head 3 per bank of cylinders 1 a and 1 b , which is delimited on the outside by a cylinder head cover 4 . The cylinder head 3 is assembled from a cylinder head lower part 5 and a camshaft housing 6 .

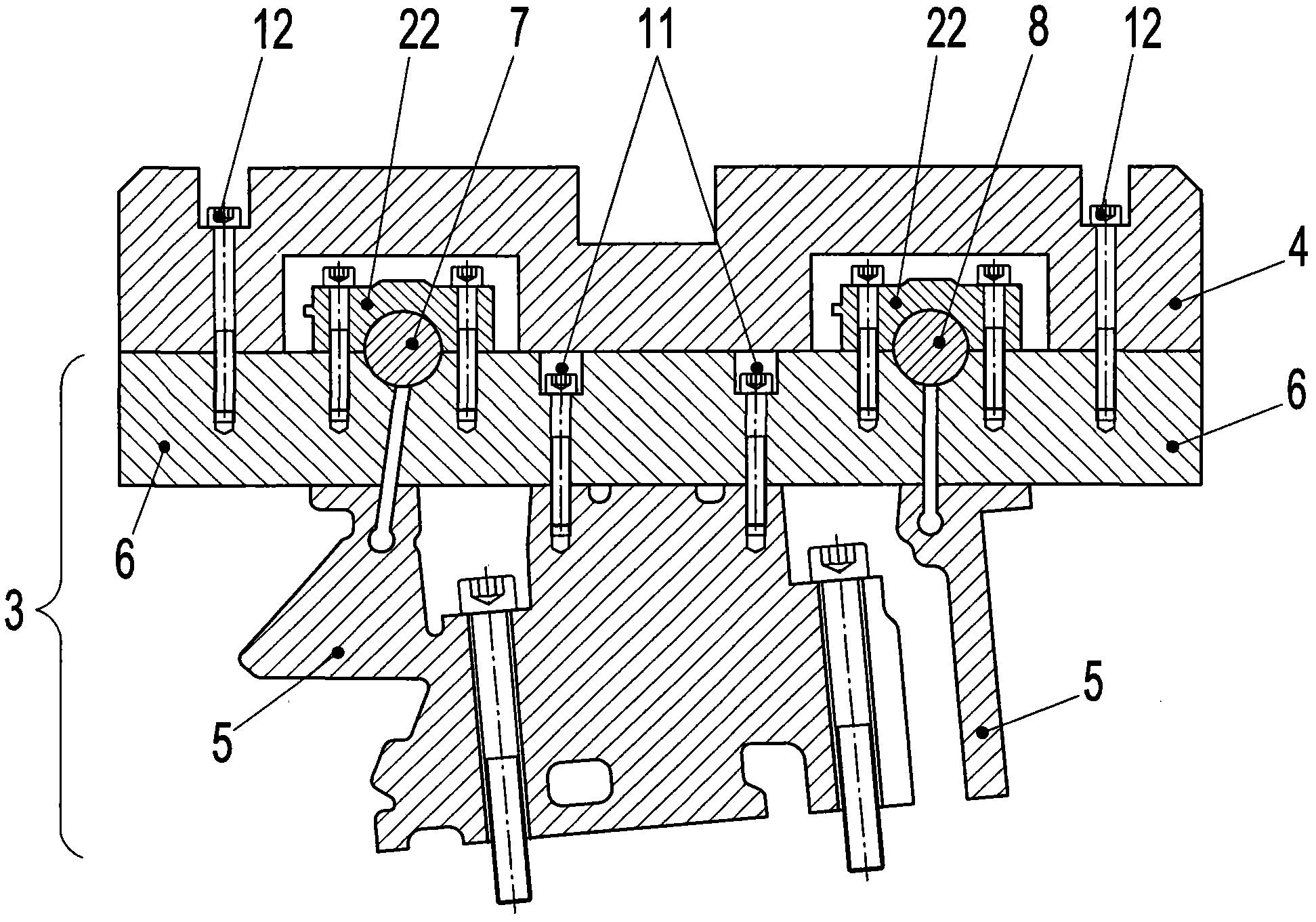

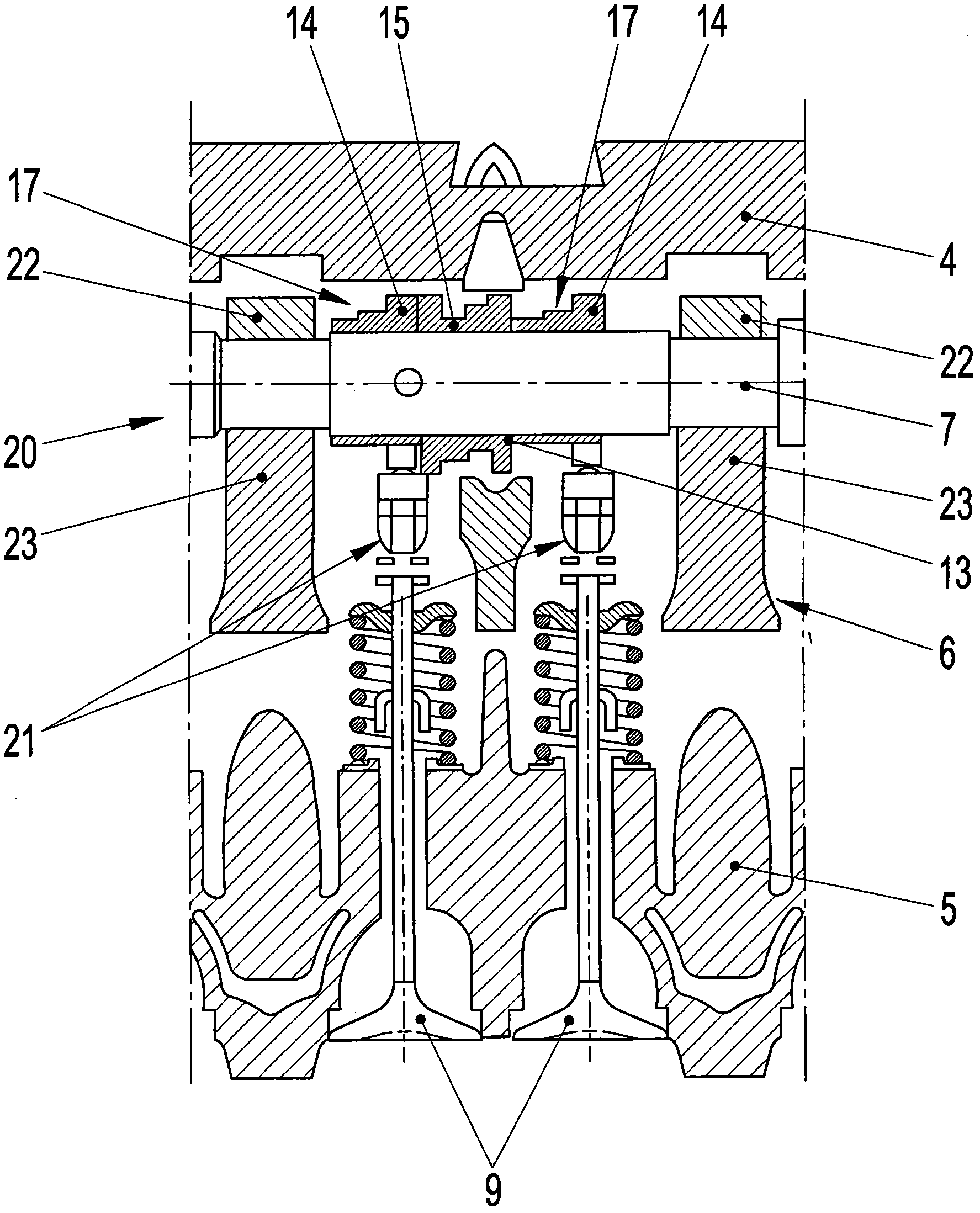

[0020] Such as figure 2 As mentioned, an intake camshaft 7 and an exhaust camshaft 8 are mounted in the camshaft housing 6 for controlling the gas exchange valves of the internal combustion engine 1 . According to the invention, the camshaft housing 6 is attached as a pre-assembled unit to the cylinder head lower part 5 and is screwed to the latter. After the camshaft housing 6 is mounted on the cylinder head lower part 5 , the cylinder head cover 4 is attached to the camshaft housing 6 . A plurality of bolts 12 are provided for fastening the cylinder head cover 4 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com