Pile sinking device and pile sinking method for prestressed centrifugal pipe piles by hydraulic method in middle excavation

A centrifugal tube and prestressing technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of difficult quality assurance, high cost, high cost, etc., and achieve the effect of ensuring safety, high efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

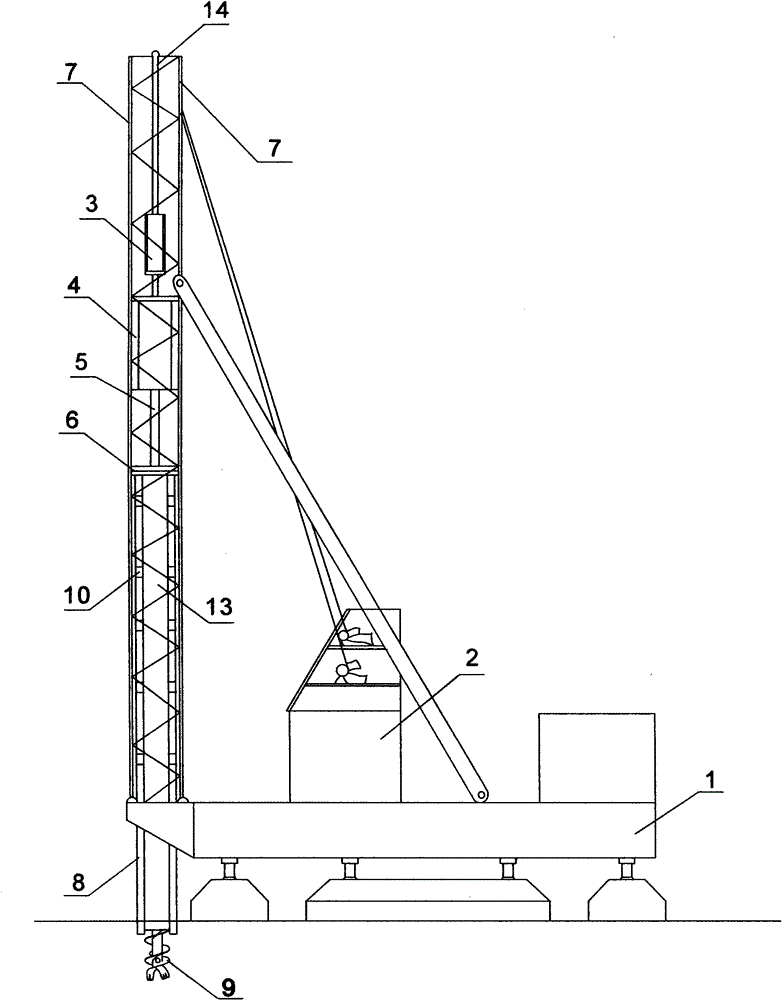

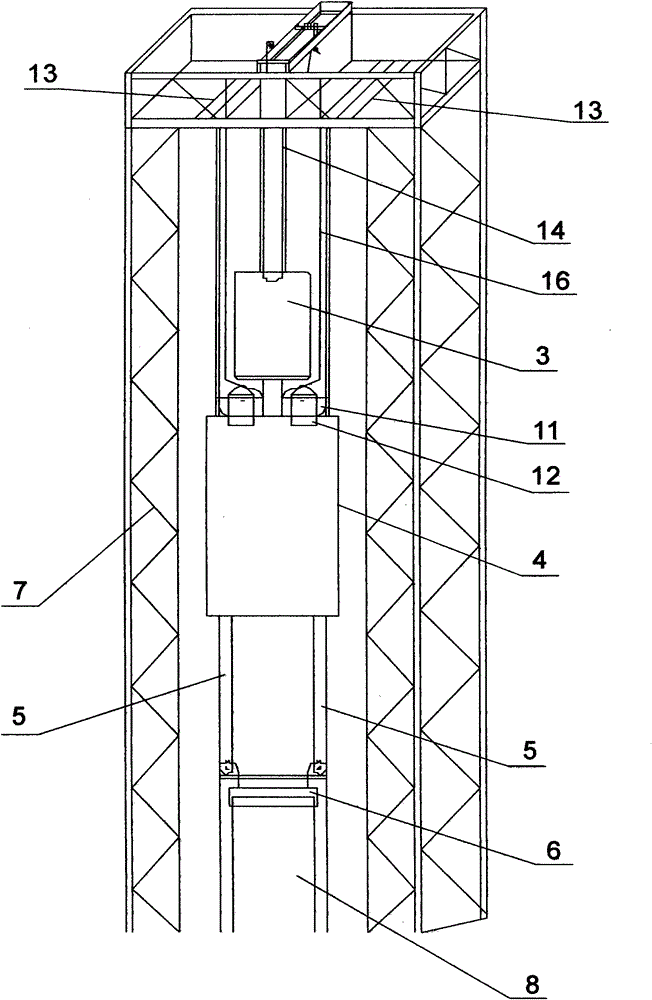

[0027] Such as Figure 1-2 A mid-digging hydraulic method prestressed centrifugal pile sinking device is shown, including a main machine 1, a winch 2 installed on the main machine 1, a support 7, a reaction force frame 13 installed on the support 7, a power head 3, and a soil fetching device. Box 4, wire ropes 14, 16, the power head 3 is installed inside the bracket 7, the upper end of the power head 3 is connected with a wire rope 14, and the wire rope 14 is connected with the winch 2 through the top of the bracket 7, and the The bottom of the power head 3 is connected with the soil-borrowing drill rod 9, and the soil-borrowing drill rod 9 passes through the soil-borrowing box 4, the piston rod 5 and the centrifugal pile 8 to reach the bottom of the device, and the inside of the soil-borrowing box 4 is installed with The piston rod 5, the lower end of the piston rod 5 is connected with the pile cap 6, and the centrifugal pipe pile 8 is placed at the lower end of the pile cap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com