Servo leading-edge paper-feeding mechanism for corrugated paper

A technology of paper feeding mechanism and servo leading edge, applied in object supply, program control in sequence/logic controller, pile separation, etc., can solve problems such as precision defects, equipment stuck, chain elongation, etc., to ensure overprinting Accuracy, increase paper feeding speed, and avoid the effect of inaccurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

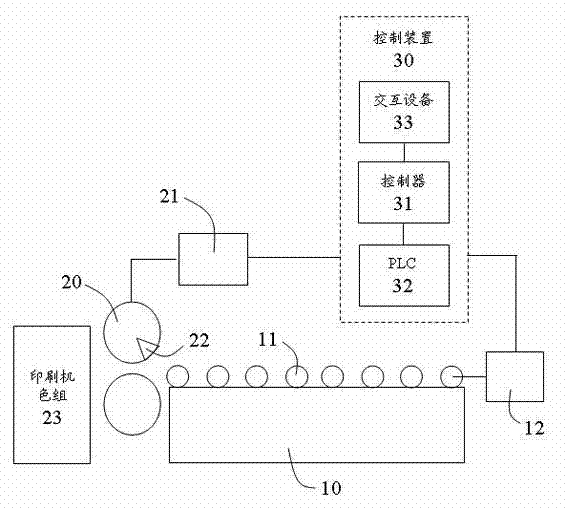

[0013] refer to figure 1 As shown, the present invention discloses a corrugated paper servo leading edge paper feeding mechanism, which includes the following main components: a worktable 10 , an electronic cam 20 and a control device 30 .

[0014] A set of paper feeding wheels 11 is arranged on the workbench 10, and the corrugated paper is placed on the paper feeding wheels 11. The rotation of the paper feeding wheels 11 drives the corrugated paper to move, and the paper feeding wheels 11 are driven by a paper feeding wheel driving mechanism 12.

[0015] The electronic cam 20 is driven by a servo motor 21 to rotate. The electronic cam 20 has a vacuum suction port 22. In one embodiment, the vacuum suction port 22 can be connected to a motor for vacuum extraction. The electronic cam 20 is arranged between a set of paper feed rollers 11 and the color group 23 of the printing machine, and the corrugated paper is sucked from the paper feed rollers 11 to the electronic cam 20 by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com