Bearing seat of working roller of cold rolling machine

A technology for work rolls and chocks, which is applied in the direction of metal rolling mill stands, metal rolling stands, and metal rolling, and can solve the problem of easy scratches on work roll chocks and small liners, which affect the rolling accuracy of rolling mills and product quality. Quality is difficult to control and other problems, to achieve the effect of simple structure, improved production efficiency and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with specific drawings and embodiments.

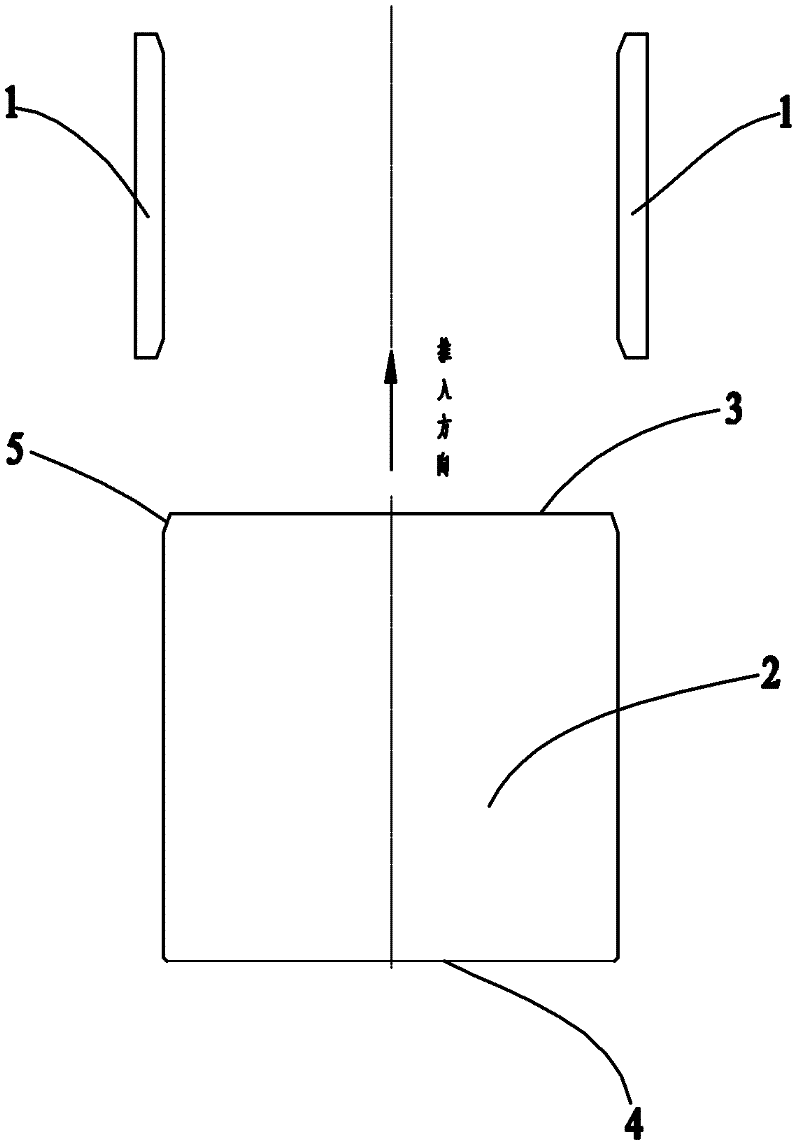

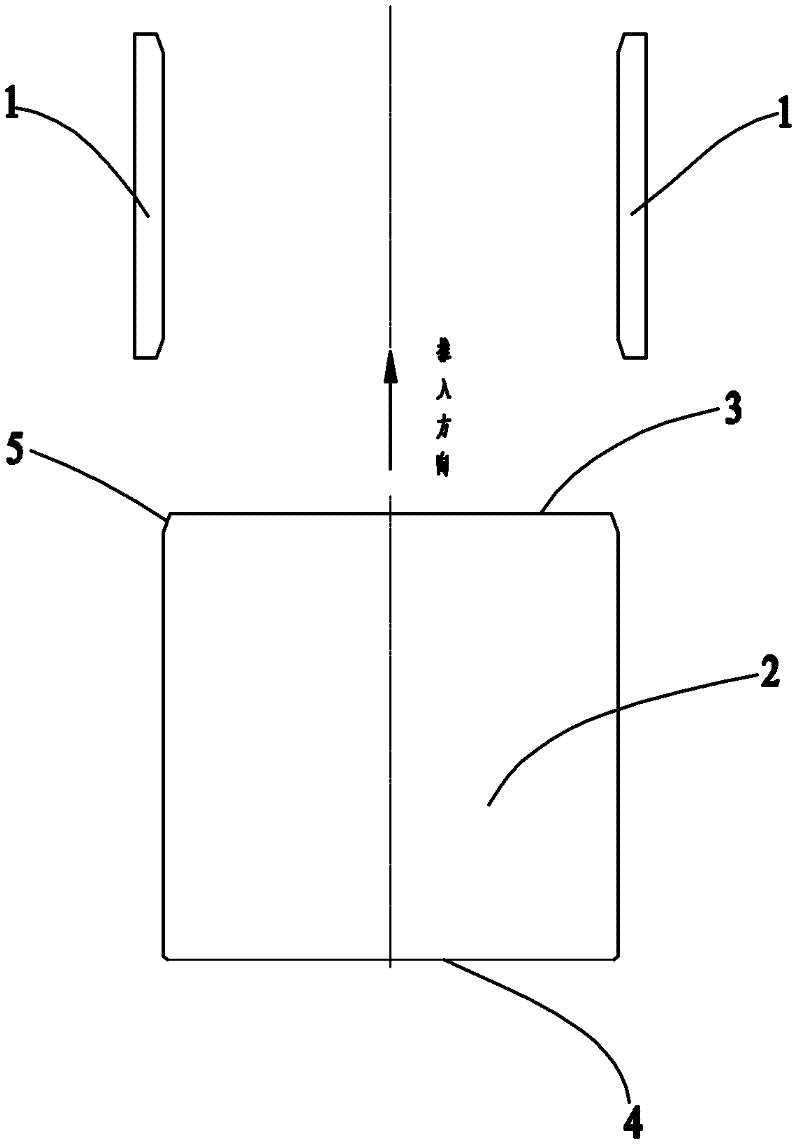

[0010] Such as figure 1 Shown: the frame small liner 1, the work roll bearing housing body 2, the first end 3, the second end 4 and the chamfer 5.

[0011] Such as figure 1 Shown: the cold rolling mill work roll chock includes a work roll chock body 2, the work roll chock body 2 includes a first end 3 and a second end 4, at the first end of the work roll chock body 2 3 is provided with symmetrically distributed chamfers 5, and the size of the chamfers 5 is 10×15°.

[0012] In a four-high cold rolling mill, symmetrically distributed chamfers 5 are provided on the first end 3 of the work roll chock body 2, so that when the work roll is loaded into the stand through the work roll chock body 2, the first end 3 chamfer 5, as a guide, it is easy to install the work roll system into the frame, avoiding the difficulty of the work roll system entering the frame when changin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com