Capacitance type touch member and method for producing the same, and capacitance type touch detection device

A touch element, capacitive technology, applied in the field of capacitive touch element and its manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0113] A capacitive touch element, a capacitive touch detection device, and a method of manufacturing the capacitive touch element according to Embodiment 1 of the present invention will be described below. In this case, carbon nanotubes are used as carbon nanolinear structures.

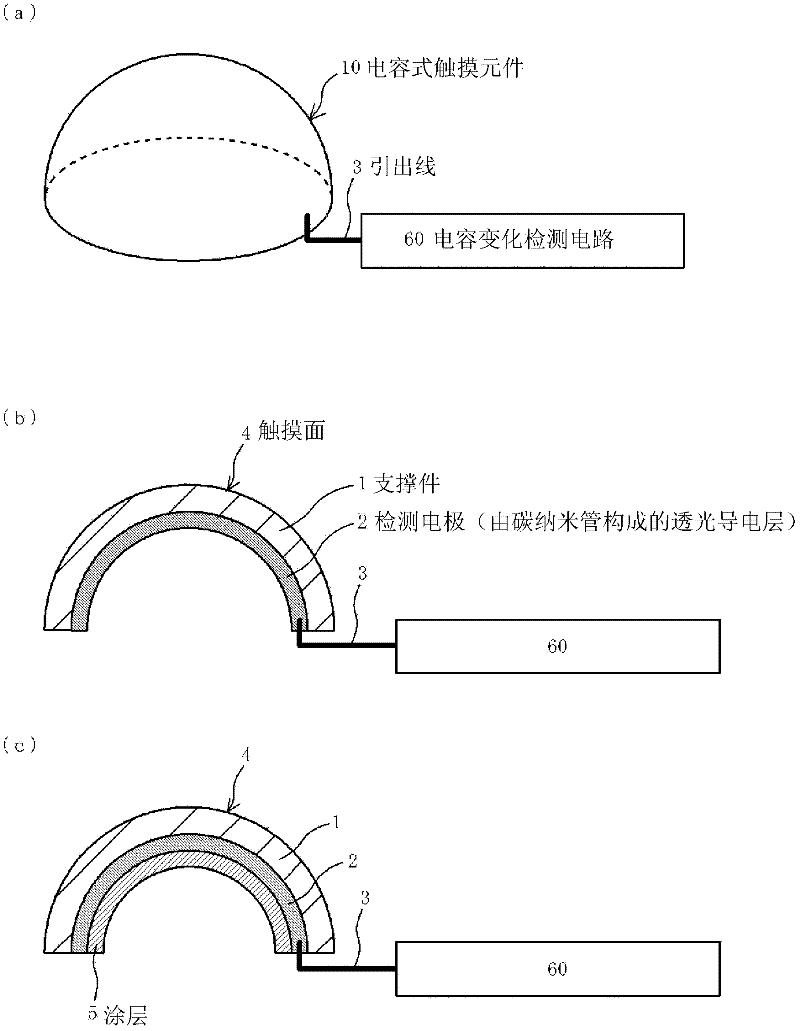

[0114] figure 1 (a) is a perspective view showing the structure of the capacitive touch detection device according to Embodiment 1, figure 1 (b) Its cross-sectional view. The capacitive touch detection device is composed of a capacitive touch element 10 based on the first capacitive touch element of the present invention and a capacitance change detection circuit 60 .

[0115] The capacitive touch element 10 includes a film-shaped or plate-shaped support 1 made of insulating material and having a three-dimensional shape, arranged on at least a part of one surface of the support 1 and composed of a light-transmitting conductive layer containing carbon nano-linear structures. The detection electro...

Embodiment approach 2

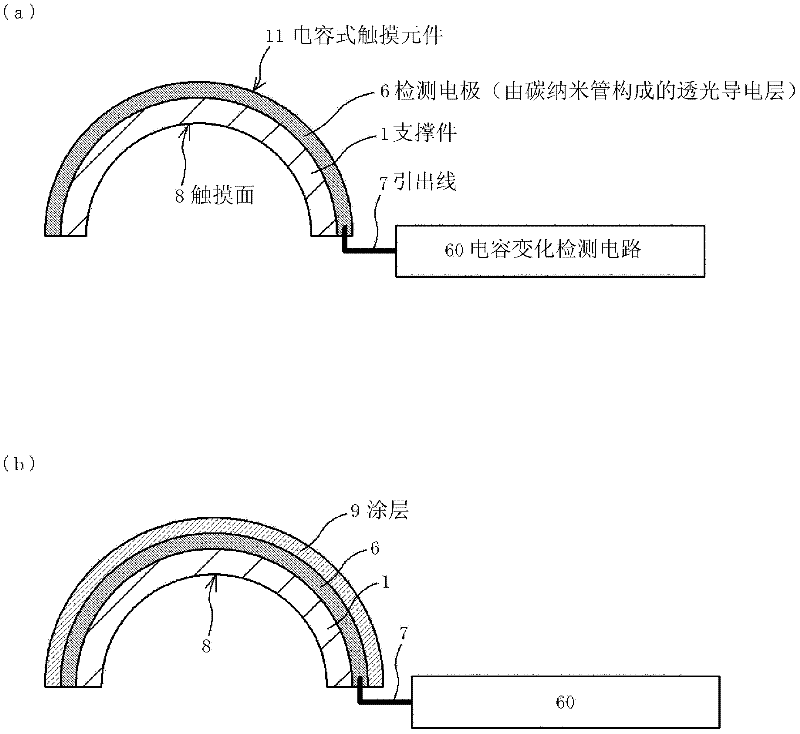

[0145] A capacitive touch element according to Embodiment Mode 2 of the present invention will be described below.

[0146] Figure 5 is a cross-sectional view showing the structure of the capacitive touch detection device according to the second embodiment. The capacitive touch detection device is composed of a capacitive touch element 20 based on the second capacitive touch element of the present invention and a capacitance change detection circuit 60 .

[0147] exist Figure 5 In the capacitive touch element 20 shown in (a), the detection electrode 6 is arranged on the outer surface (convex surface) of the hemispherical support 1, and the protective film 22 coated with the detection electrode 6 is laminated on the outer surface, so that the surface of the protective film 22 Serves as the touch surface 23 . In addition, in Figure 5 In the capacitive touch element 24 shown in (b), the detection electrode 2 is provided on the inner surface (concave surface) of the support...

Embodiment approach 3

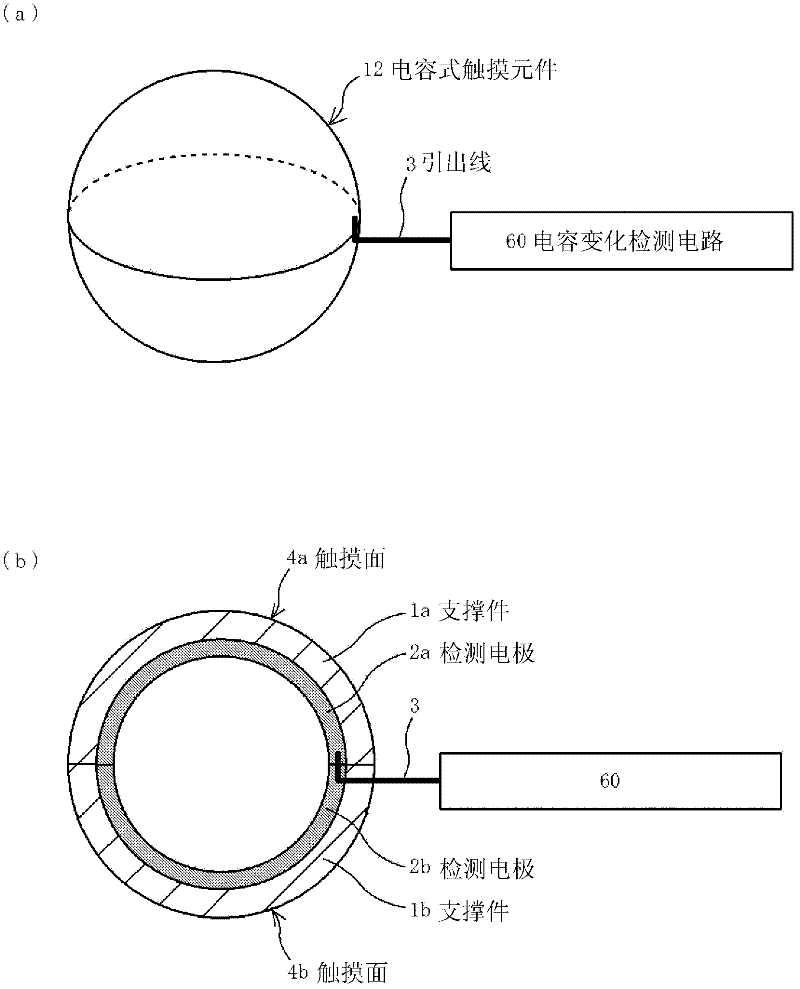

[0151] A capacitive touch element according to Embodiment Mode 3 of the present invention will be described below.

[0152] Figure 6 is a cross-sectional view showing the structure of the capacitive touch detection device according to Embodiment 3. The capacitive touch detection device is composed of a capacitive touch element 30 and a capacitance change detection circuit 60 based on the third capacitive touch element of the present invention.

[0153] exist Figure 6 In the shown capacitive touch element 30, the detection electrode 6 is provided on the outer surface (convex surface) of the hemispherical support 1, and the protective film 22 coated with the detection electrode 6 is laminated on the outer surface, so that the surface of the protective film 22 is used as a touch sensor. Surface 23. Further, detection electrode 2 is provided on the inner surface (concave surface) of support 1 on which protective film 25 coating detection electrode 2 is laminated so that the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com