Gas cylinder wound continuous curing furnace

A curing furnace and gas cylinder technology, which is applied in the field of continuous curing treatment devices, can solve the problems of wasting material costs and manufacturing hours, wasting human resources, and reducing cost performance, so as to save material costs and manufacturing hours, reduce operating costs, and improve cost performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

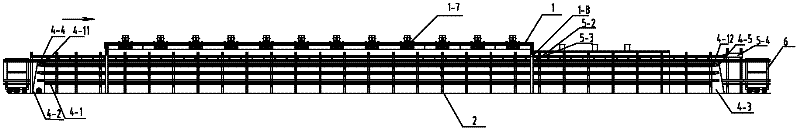

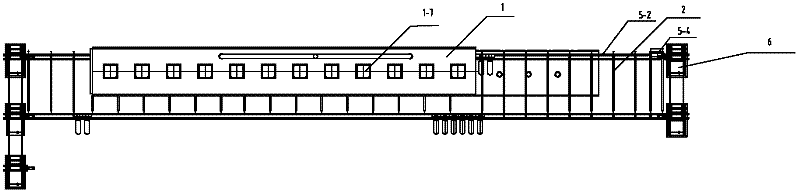

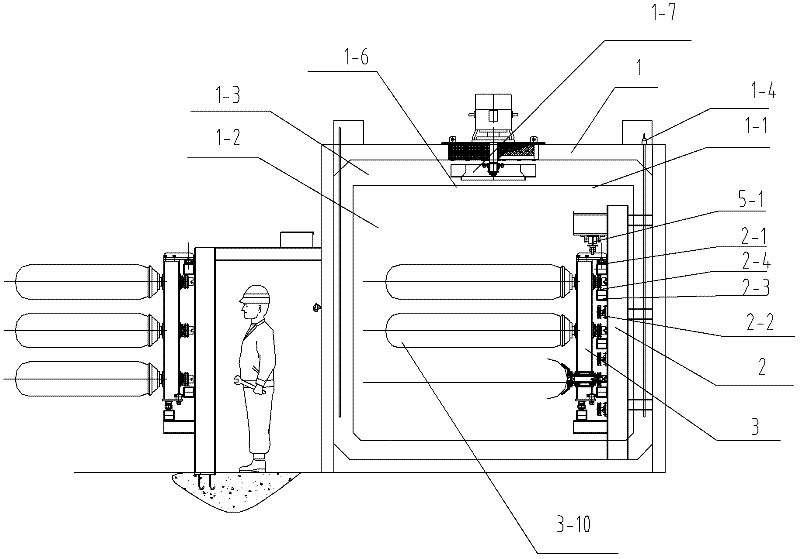

[0026] see figure 1 and figure 2 , in the present embodiment, the gas cylinder winding continuous curing furnace comprises a furnace body 1, fourteen frock supports 2 fixed inside and outside the furnace body 1, and three winding frock fixtures 3 for gas cylinders 3-10 to be cured are installed ( Every three gas cylinders 3-10 are a group), the rotation auxiliary transmission system for driving the gas cylinders 3-10 to rotate axially and the stepping movement for driving the winding tool fixture 3 on the fourteen tool brackets 2 stepping device.

[0027] see image 3 and Figure 4 , wherein, the inner side of body of heater 1 is provided with deflector 1-1 all around, and deflector 1-1 divides the cavity of furnace body 1 into studio 1-2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com