Pneumatic gate valve for feeding of roll squeezer

A technology of pneumatic gates and roller presses, applied in the direction of sliding valves, valve details, valve devices, etc., can solve problems such as inability to completely cut off material, inability to completely close, and affect equipment operation and operation, so as to ensure normal operation and convenience The effect of cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

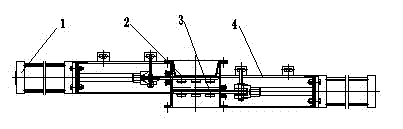

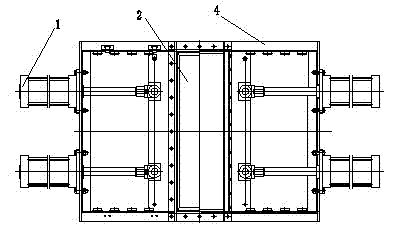

[0017] The present invention includes a housing 4 provided with a feed inlet, on which a gate valve and a drive cylinder 1 for driving its motion are provided, and the gate valve of the present invention includes a valve plate 1 2 and a valve plate 2 3 arranged up and down. , the first valve plate and the second valve plate move in reverse.

[0018] The driving cylinders include two cylinders 1 for driving the first valve plate 2 to move and two cylinders 1 for driving the second valve plate 3 to move.

[0019] When the material is cut in the present invention, the valve plate 2 may be stuck by the particles moving downward, but the valve plate 2 3 will not be stuck by the particles under the protection of the valve plate 2, so that the material can be cut off quickly and the roller The press runs smoothly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com