Thrust fluctuation active compensation type linear permanent magnet synchronous motor

A permanent magnet synchronous motor, thrust fluctuation technology, applied in electrical components, electromechanical devices, propulsion systems, etc., can solve problems such as reducing the effective thrust of the motor, and achieve elimination or reduction of thrust fluctuations, high motor efficiency, and small thrust fluctuations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

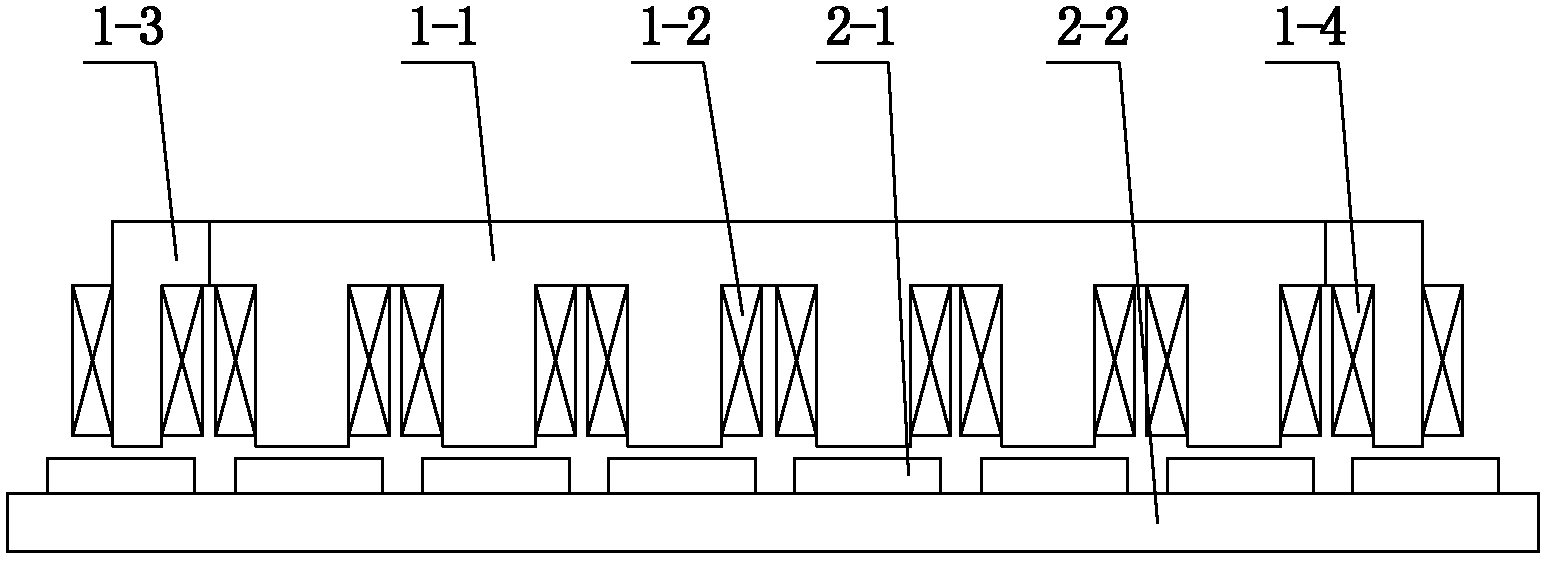

[0053] Specific implementation mode one: the following combination Figure 1 to Figure 5Describe this embodiment, the thrust fluctuation active compensation linear permanent magnet synchronous motor described in this embodiment includes a primary and a secondary, an air gap between the primary and the secondary, the primary includes an armature core 1-1 and an electric motor An armature winding 1-2, the armature winding 1-2 is a surface mount structure,

[0054] The primary also includes a thrust fluctuation compensation unit, which is composed of a compensation core 1-3, a compensation winding 1-4 and a compensation controller,

[0055] Compensation core 1-3 is a slotted structure, compensation core 1-3 is fixedly connected with armature core 1-1, compensation winding 1-4 is wound on all compensation teeth of compensation core 1-3, and the lead-out of compensation winding 1-4 Connect the current output terminal of the compensation controller with a line;

[0056] The compen...

specific Embodiment approach 2

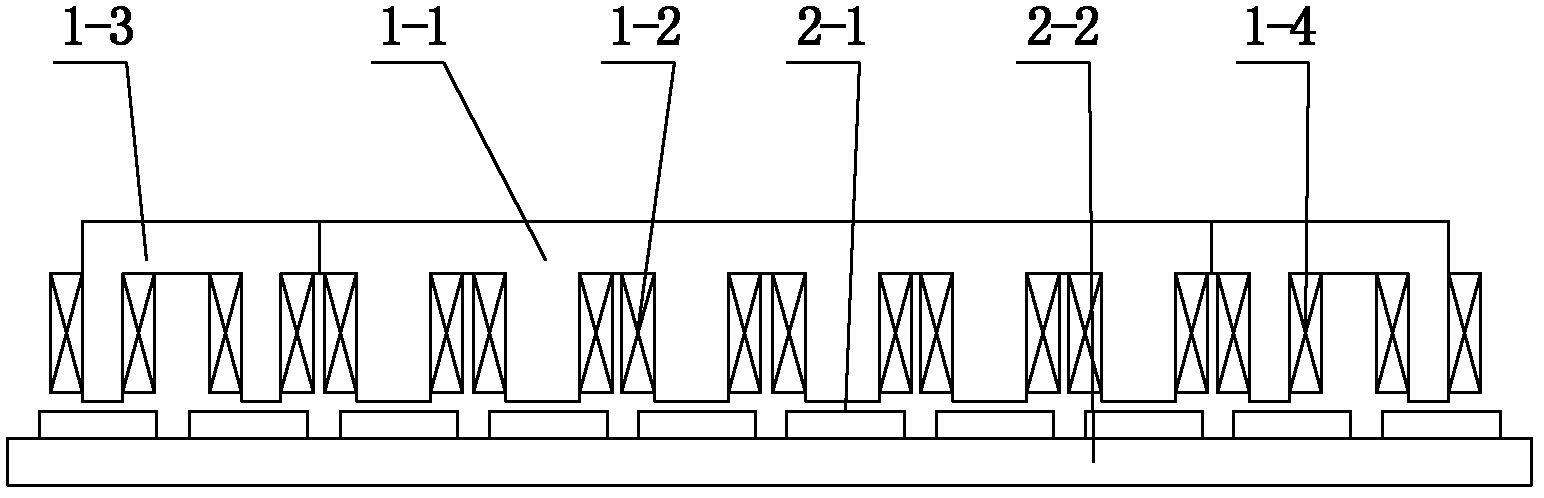

[0060] Specific implementation mode two: the following combination Figure 1 to Figure 5 Describe this embodiment, the thrust fluctuation active compensation linear permanent magnet synchronous motor described in this embodiment includes a primary and a secondary, an air gap between the primary and the secondary, the primary includes an armature core 1-1 and an electric motor The armature winding 1-2, the primary is a slotted structure, the armature winding 1-2 is embedded in the slot of the armature core 1-1,

[0061] The primary also includes a thrust fluctuation compensation unit, which is composed of a compensation core 1-3, a compensation winding 1-4 and a compensation controller,

[0062] Compensation core 1-3 is a slotted structure, compensation core 1-3 is fixedly connected with armature core 1-1, compensation winding 1-4 is wound on all compensation teeth of compensation core 1-3, and the lead-out of compensation winding 1-4 Connect the current output terminal of the...

specific Embodiment approach 3

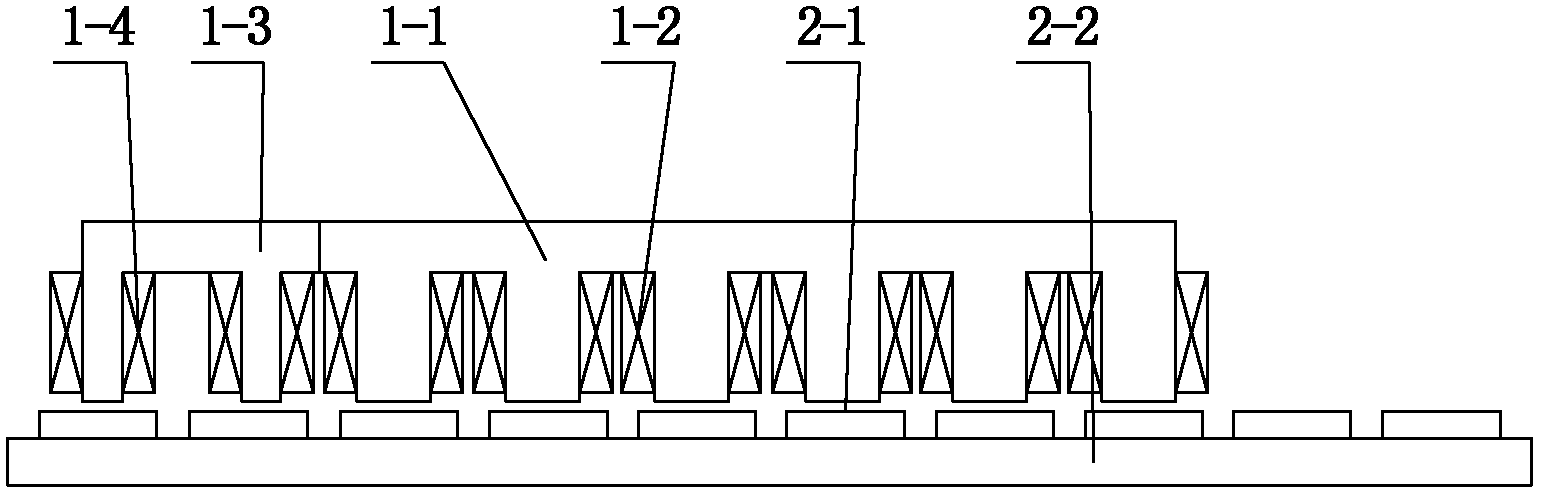

[0067] Specific implementation mode three: the following combination Figure 1 to Figure 5 Describe this embodiment, the thrust fluctuation active compensation linear permanent magnet synchronous motor described in this embodiment includes a primary and a secondary, an air gap between the primary and the secondary, the primary includes an armature core 1-1 and an electric motor An armature winding 1-2, the armature winding 1-2 is a surface mount structure,

[0068] The primary also includes a thrust fluctuation compensation unit, which is composed of a compensation core 1-3 and a compensation winding 1-4,

[0069] Compensation core 1-3 is a slotted structure, compensation core 1-3 is fixedly connected with armature core 1-1, compensation winding 1-4 is wound on all compensation teeth of compensation core 1-3, compensation winding 1-4 is connected with phase The armature windings 1-2 on the teeth adjacent to the armature core 1-1 are connected in series;

[0070] The compensa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com