Mechanical latching mechanism of explosion-proof switching box

A mechanical lock and switch box technology, applied in the direction of electrical switches, electrical components, circuits, etc., can solve the problems of complicated operation, damage and misoperation of maintenance personnel, etc., to prevent coal mine gas and dust explosion, reasonable structure design, Ensure the effect of construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

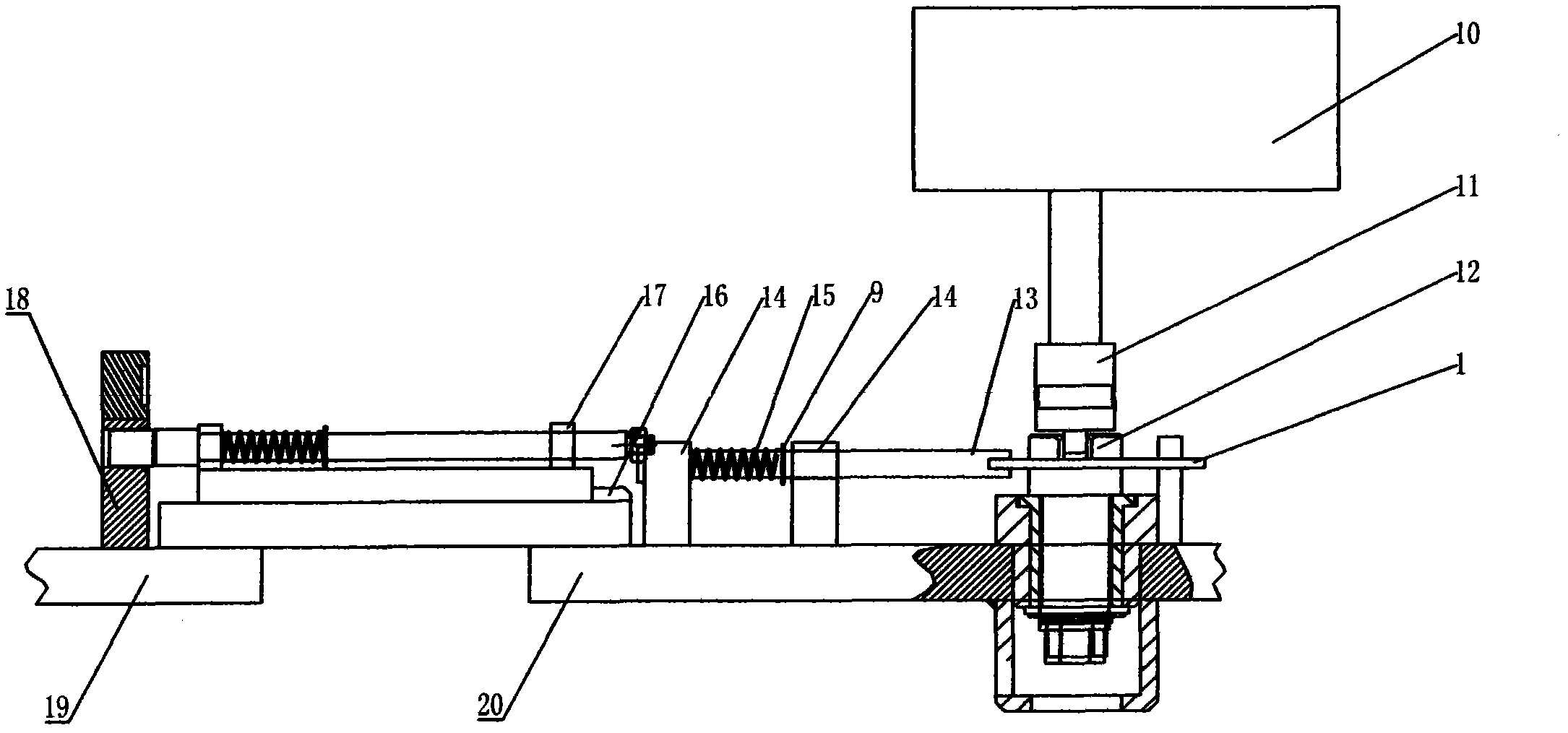

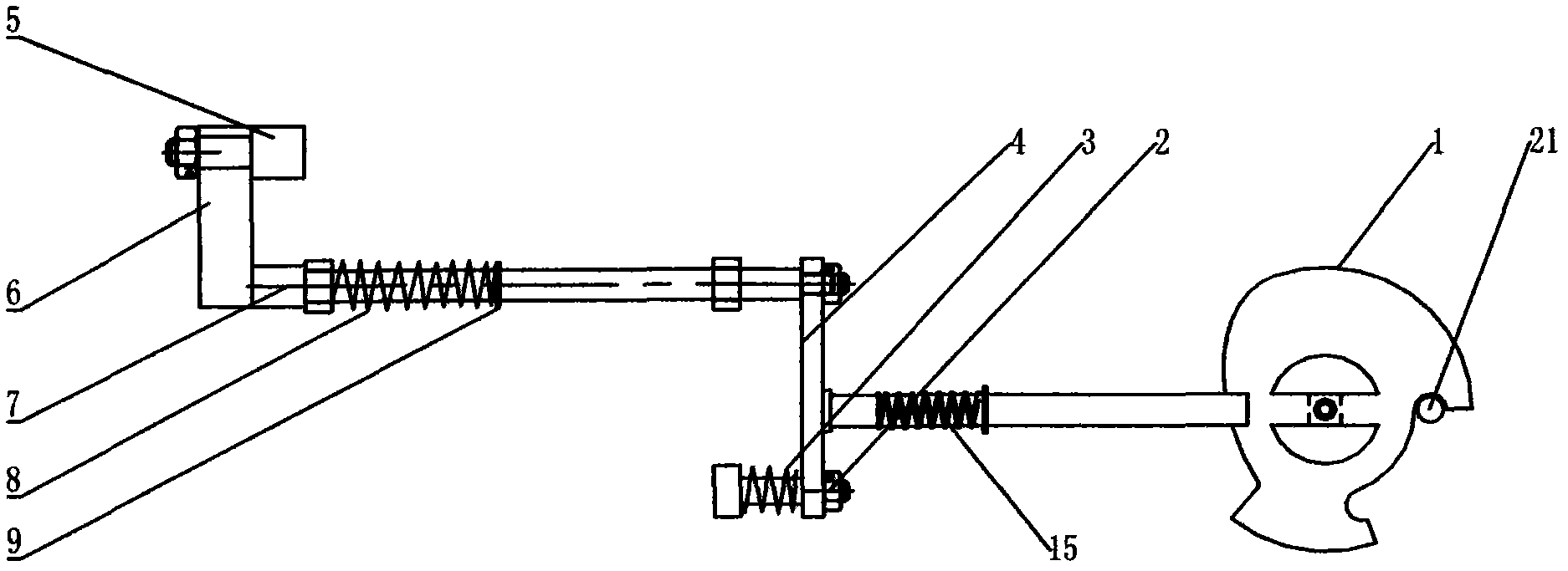

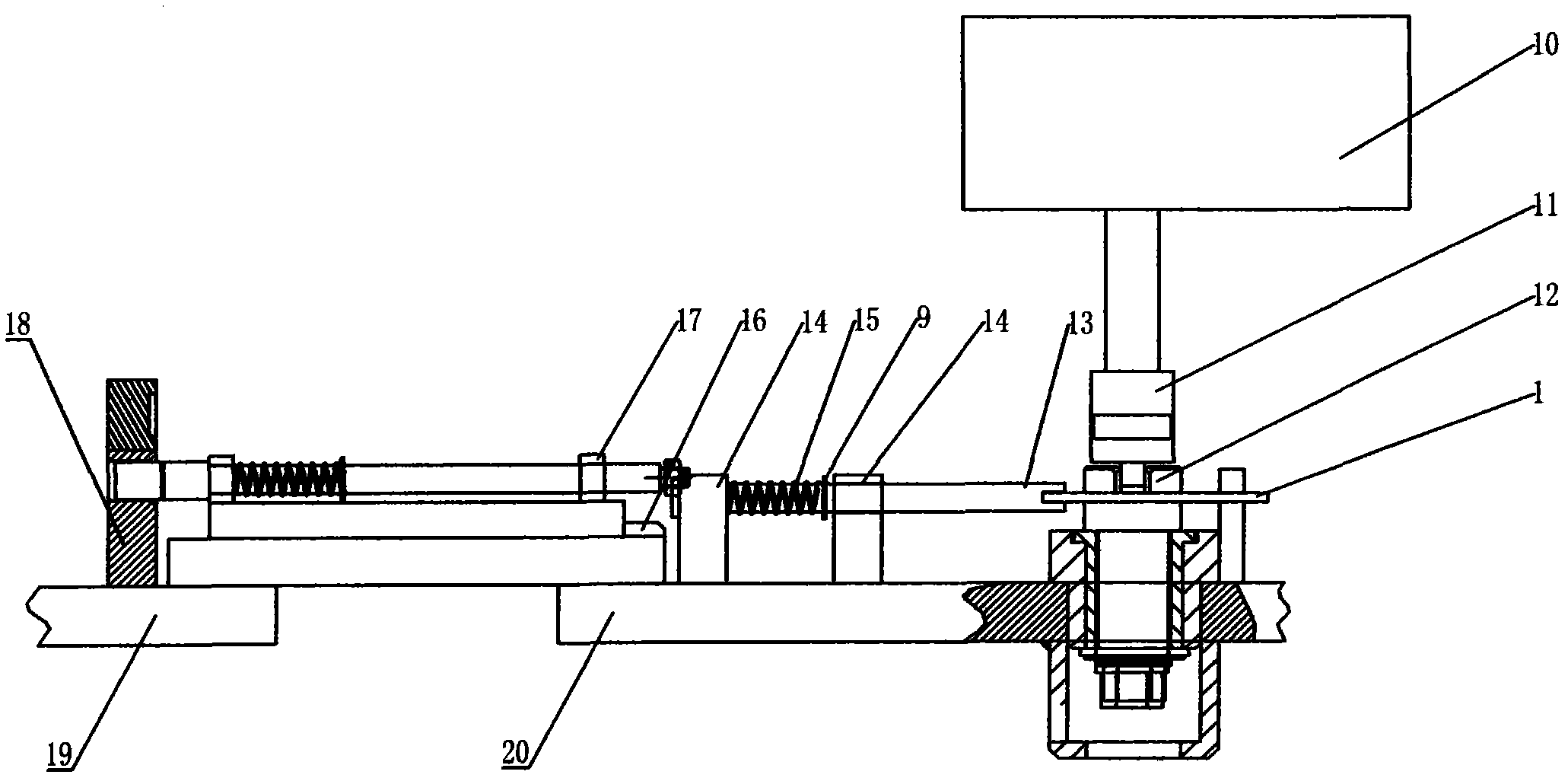

[0013] A mechanical locking mechanism for a flameproof switch box, which is arranged on the inner side of the left door 19, the inner side of the right door 20, and the inner side of the box between the left door 19 and the right door 20, and the inner side of the right door 20 is provided with a rotating shaft 12 , locking limit plate 1, right door locking lever 13 and right door locking shaft seat 14, described rotating shaft 12 is rotatably installed on the right door 20, and rotating shaft 12 is connected with the isolating switch 10 in the casing after the right door 20 is closed. The operating rod 11 is connected to the rotating shaft 12, and the operating handle is connected to the rotating shaft 12. The working state of the isolating switch 10 can be controlled through the operating handle. The rotation of the bit plate 1 can drive the left and right movement of the right door locking lever 13, thereby controlling the opening and closing of the locking mechanism; the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com