Automatic vacuum oil injection method and tool for unmanned mutual inductor

A transformer and oil injection technology, applied in the field of transformers, can solve the problems of uncontrollable oil injection speed, no film degassing, manual operation, etc., and achieve the effect of avoiding human quality factors, slowing down production bottlenecks, and controllable oil injection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

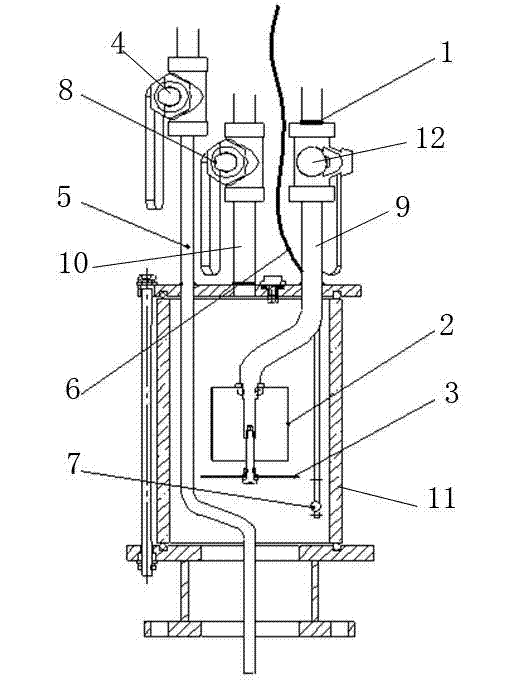

[0015] An unattended transformer automatic vacuum oil filling tool, comprising a speed-limiting oil nozzle 1, a ball valve, an oil suction pipe 5, a liquid level sensor 7, an oil injection pipe 9, a vacuum pipe 10, and an oil cup 11. The oil cup is provided with an oil injection pipe, an oil suction pipe The speed-limiting nozzle is arranged on the oil injection pipe, the ball valves 4 and 8 are arranged on the oil suction pipe and the vacuum pipe, and the liquid level sensor is arranged in the oil cup.

[0016] In the oil cup, there are also matched film-drawing cylinders 2 and film-drawing trays 3 to process the incoming oil. The transformer oil achieves different flow rates through the speed-limiting nozzle, sprays on the inner wall of the film-drawing cylinder, and drips on the film-drawing tray. Evenly pulls the oil into a thin film to impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com