Transmission structure of PTZ (Pan/Tilt/Zoom) camera

A technology of pan-tilt camera and transmission structure, which is applied in the field of cameras, and can solve problems such as eccentricity, long force-bearing structure of the rotating shaft, displacement of the rotating shaft, etc., and achieve the effects of reducing production costs, smooth and stable rotating process, and simple matching structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the drawings and examples.

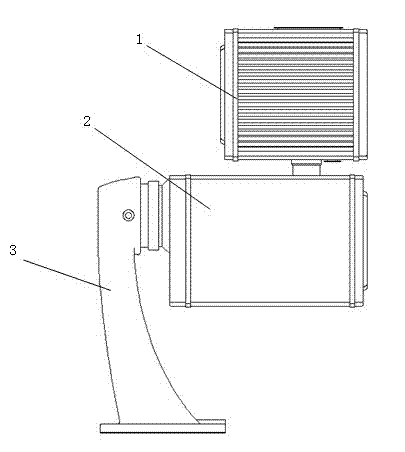

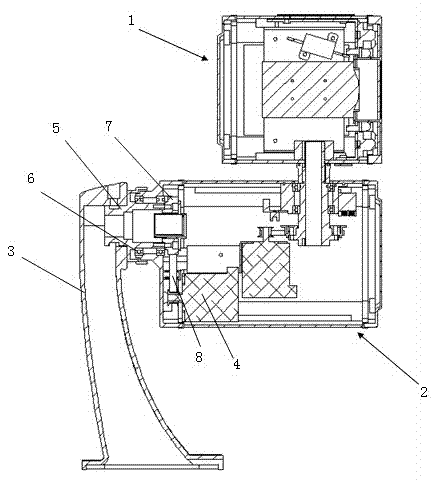

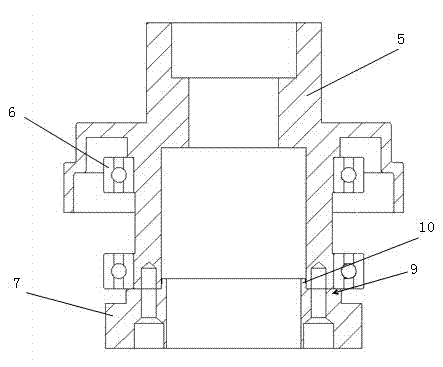

[0023] figure 1 It is a schematic diagram of the external structure of the PTZ camera; figure 2 It is the internal schematic diagram of the pan-tilt camera that has adopted the transmission structure of the pan-tilt camera of the present invention; image 3 It is a sectional view of the transmission structure of the pan-tilt camera of the present invention; Figure 4 It is a partial enlarged view of the rotating shaft and the synchronous belt pulley in the assembly position in the transmission structure of the pan-tilt camera of the present invention; Figure 5 It is a sectional view of the synchronous belt pulley in the transmission structure of the pan-tilt camera of the present invention.

[0024] Such as Figure 1 to Figure 5 Shown, the transmission structure of the pan-tilt camera of the present invention, wherein above-mentioned pan-tilt camera comprises: ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com