Multifunctional double-drum filter valve

A technology of filter valve and double cylinder, which is applied in the direction of filter separation, valve device, mechanical equipment, etc., and can solve the problems of unreliable sealing, switching valve and valve seat without sealing structure, inconvenient online cleaning work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

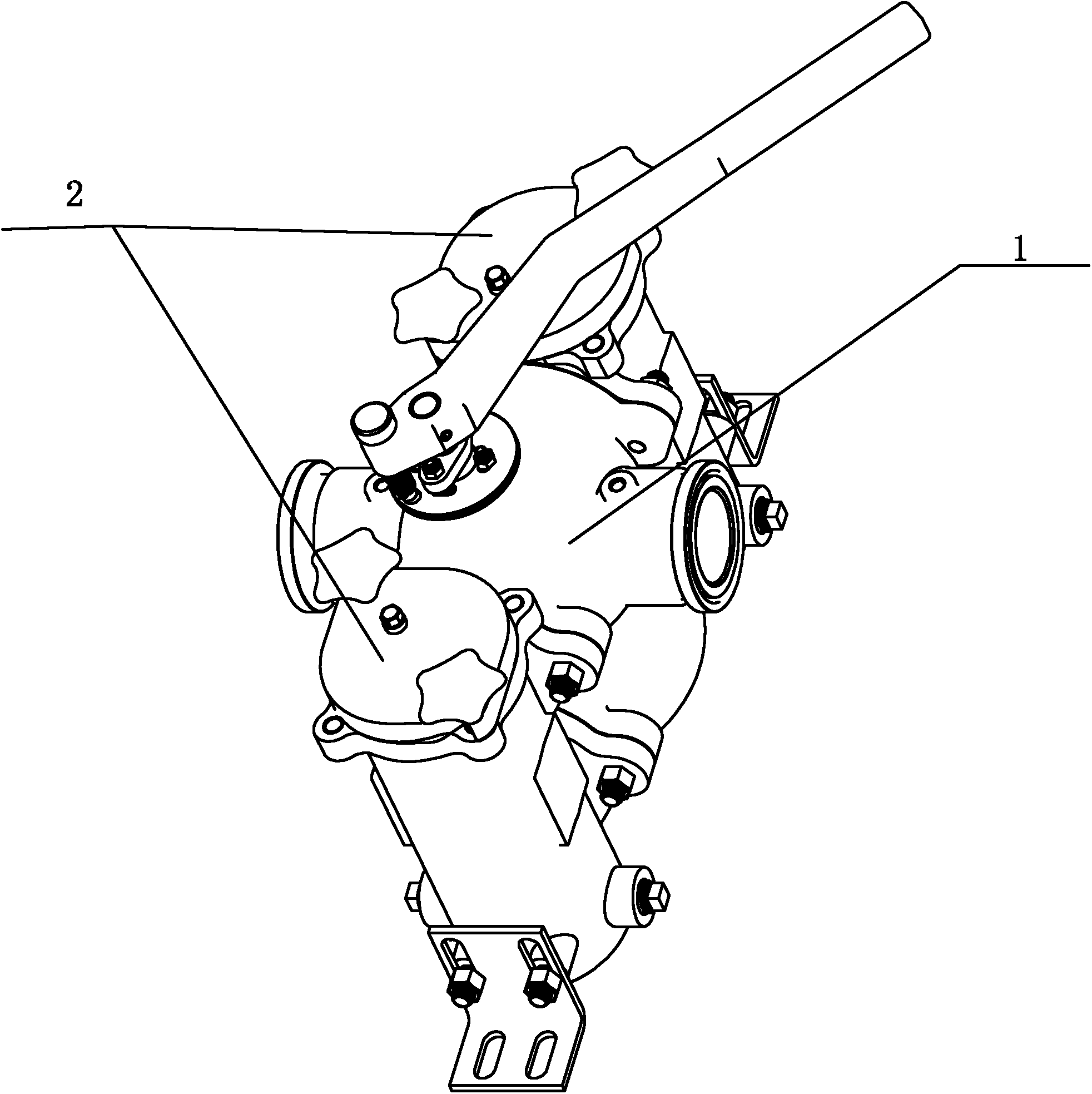

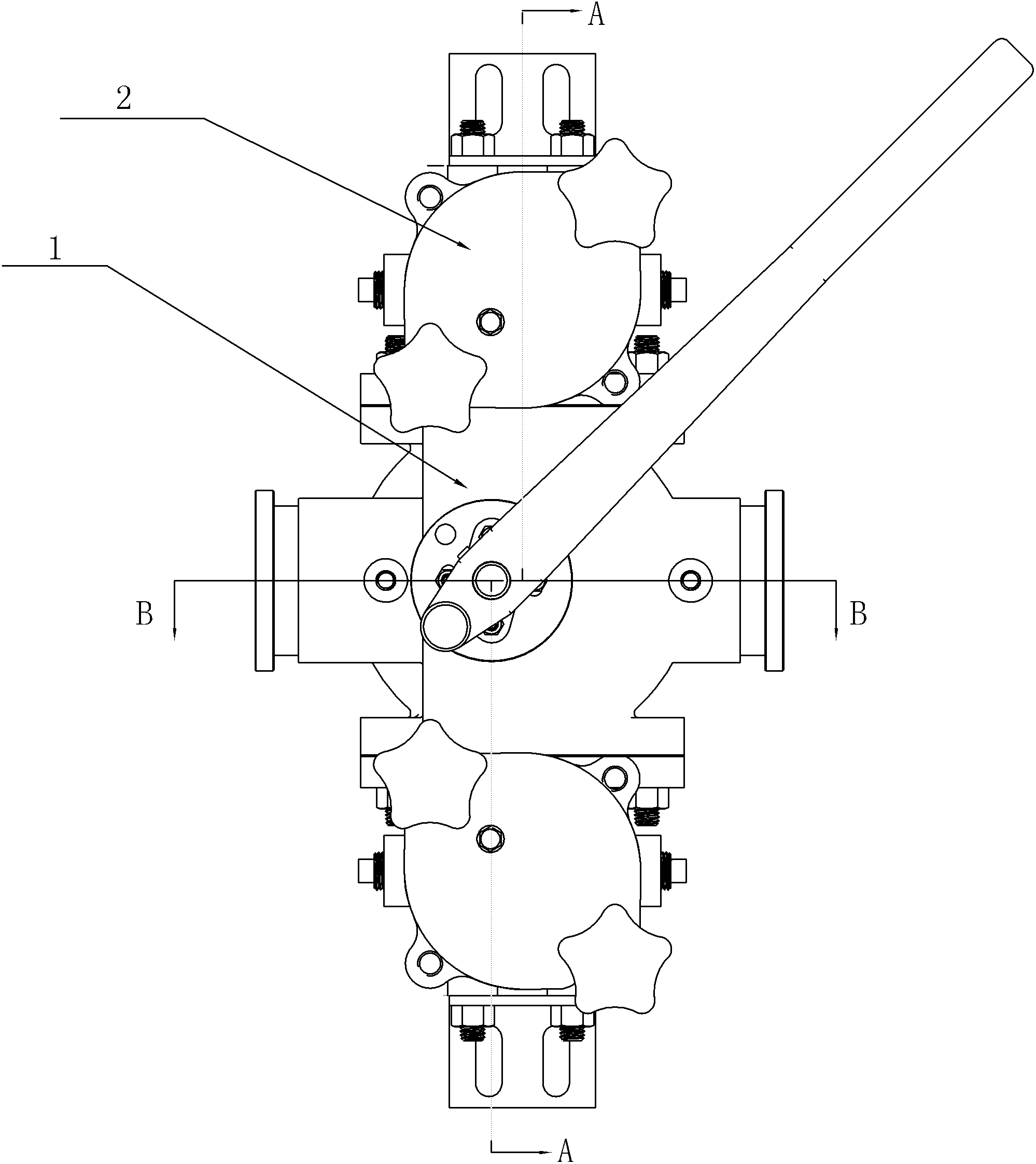

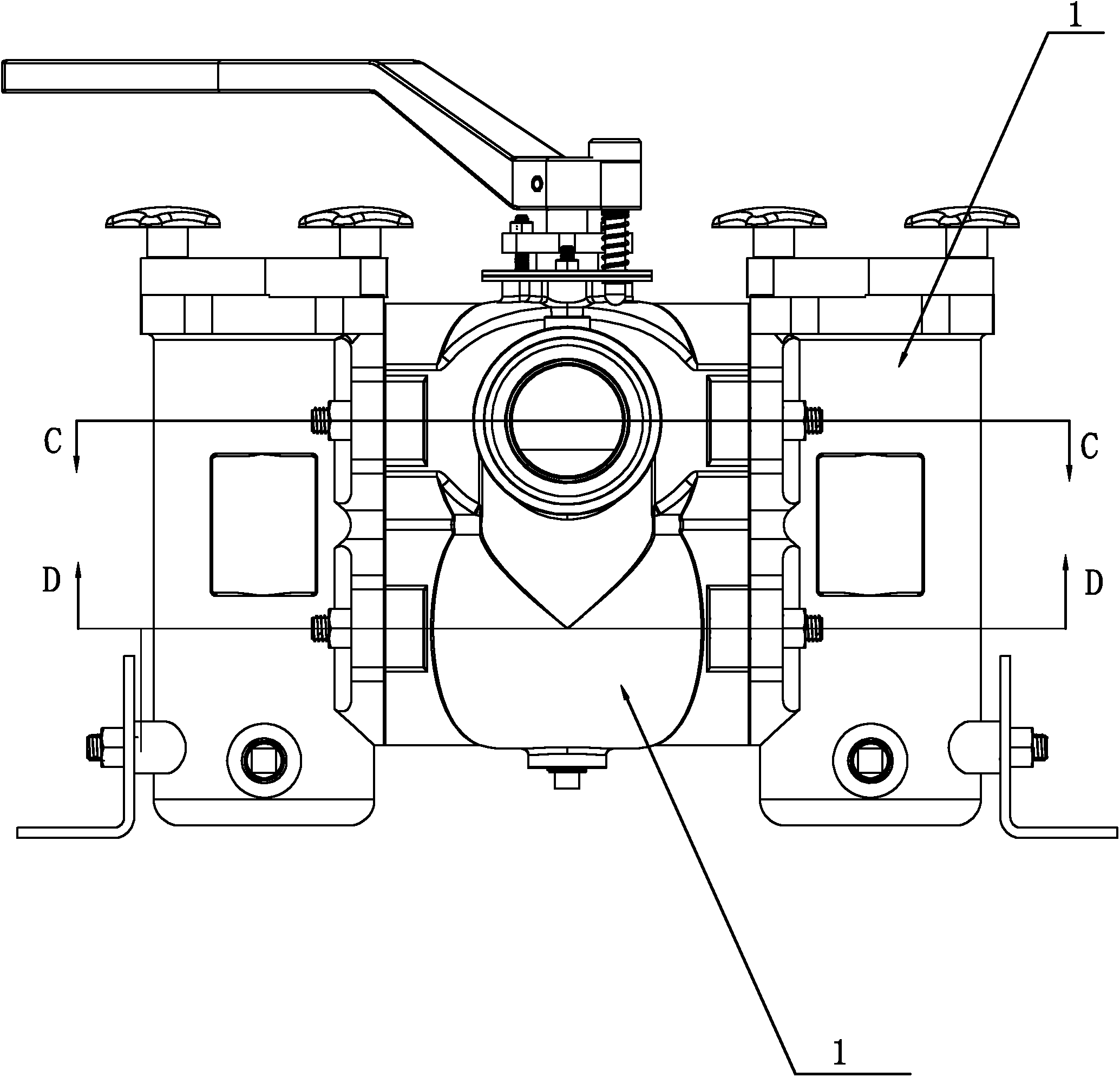

[0027] See attached figure 1 To attach Figure 11 , a double cylinder filter valve disclosed by the present invention includes a valve body 1, a fluid inlet 11 and a fluid outlet 12 arranged on the valve body 1; the top of the valve body 1 is provided with a valve shaft mounting seat, and the valve There is a stepped hole in the center of the shaft mounting seat, and several positioning blind holes are arranged around the periphery of the stepped hole; a valve cavity is provided in the valve body, and a baffle plate 15 is arranged in the valve cavity, and the baffle plate 15 separates the valve cavity into mutually independent parts. Upper and lower valve chambers 13, 14, the upper valve chamber 13 communicates with the fluid inlet 11, and the lower valve chamber 14 communicates with the fluid outlet 12; the baffle plate 15 is provided with a valve coaxial with the stepped hole on the valve shaft mounting seat. Shaft positioning mounting hole, one end of the valve shaft 3 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com