Inner cavity centering adjustment method and adjustment tool thereof

A technology of centering adjustment and inner cavity, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of undetectable, scrapped products, difficult operation, etc., to ensure the symmetry index, avoid hole wall scratches, Rotating flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better illustrate the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

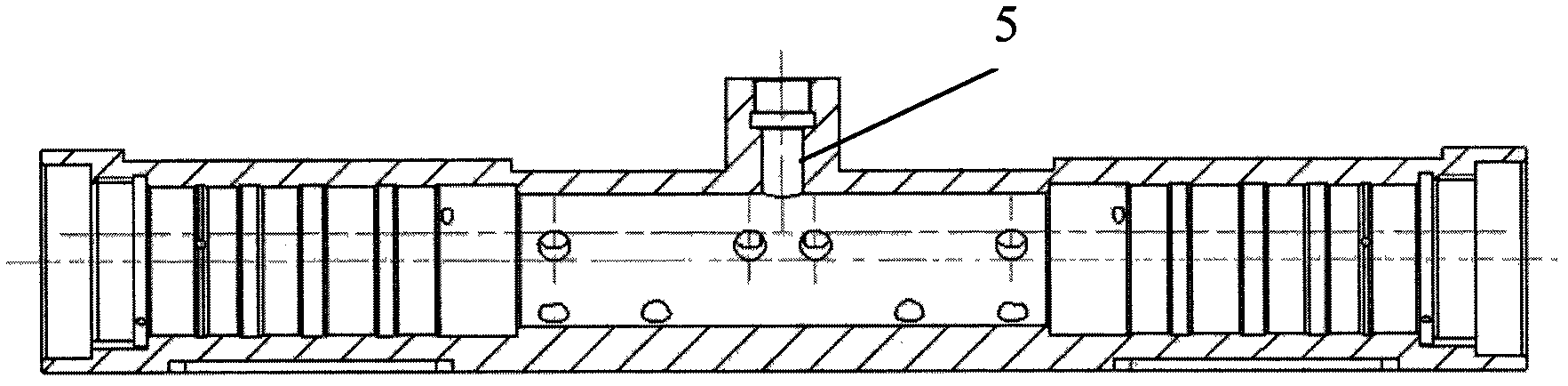

[0028] Please refer to the attached Figure 4 ~ Figure 5 . An inner cavity centering adjustment tool, including a knob 1, a positioning shaft 2 and an eccentric block 3, the eccentric block 3 is rotatably installed in the inner hole of the positioning shaft 2, one end of which is fixedly connected with the knob 1, and the other end protrudes from the positioning shaft 2, the eccentric block 3 protruding out of the positioning shaft 2 is an asymmetrical rotator with only one maximum radius, and the gap between the maximum radius b and the narrow side of the waist hole 4 of the valve sleeve is a symmetry tolerance requirement 1 / 3~1 / 5 of Figure 4 , Figure 5 shown.

[0029] In order to make the alignment adjustment have higher precision, further, such as Image 6 As shown, the gap between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com