Band saw cutting machine

A technology of saw cutting machine and frame, which is applied in the field of band saw cutting machine, which can solve the problems of difficult control of product end surface flatness, uneven product end surface, large space occupation, etc., and achieve low noise, low manufacturing cost, and space occupation small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

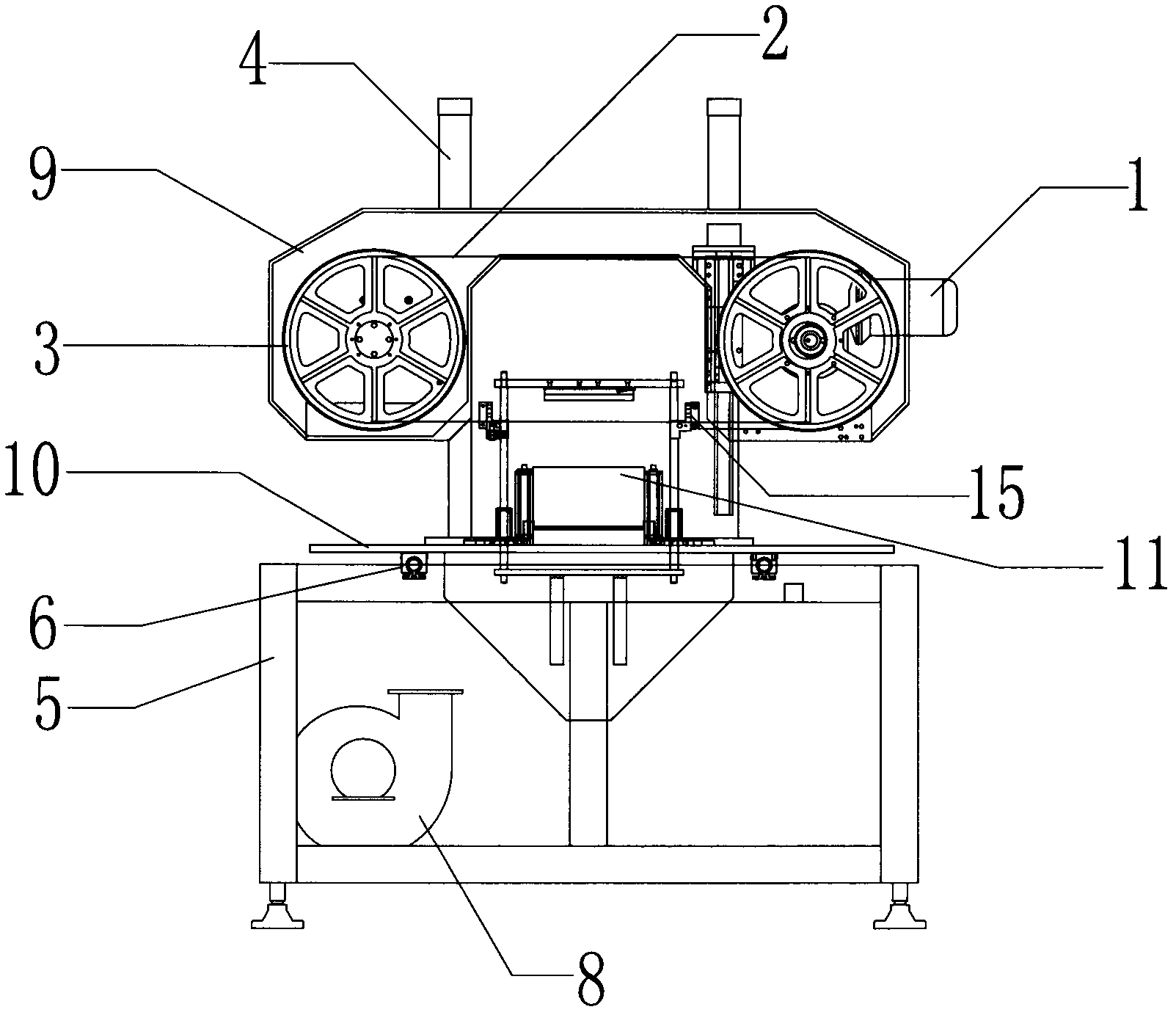

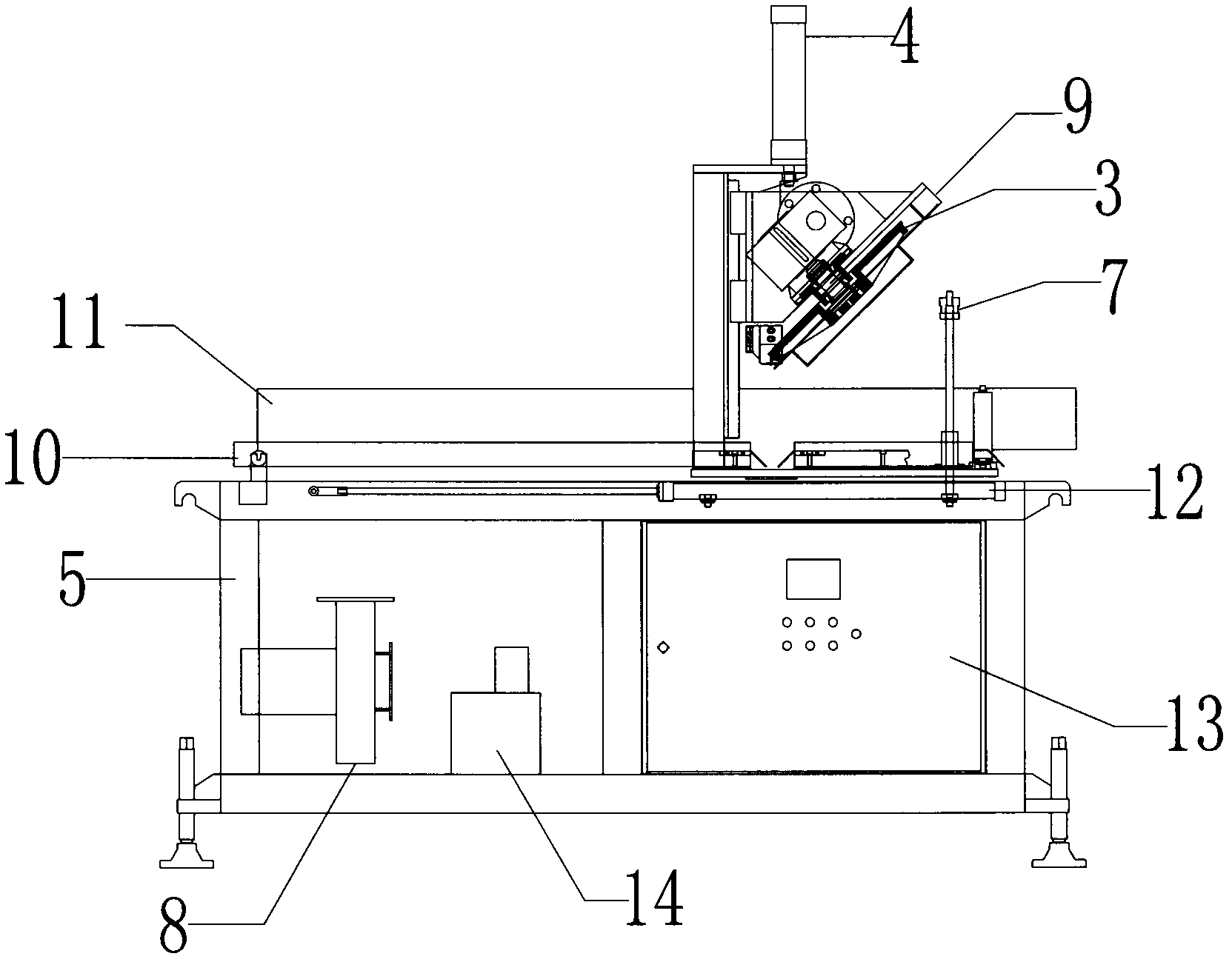

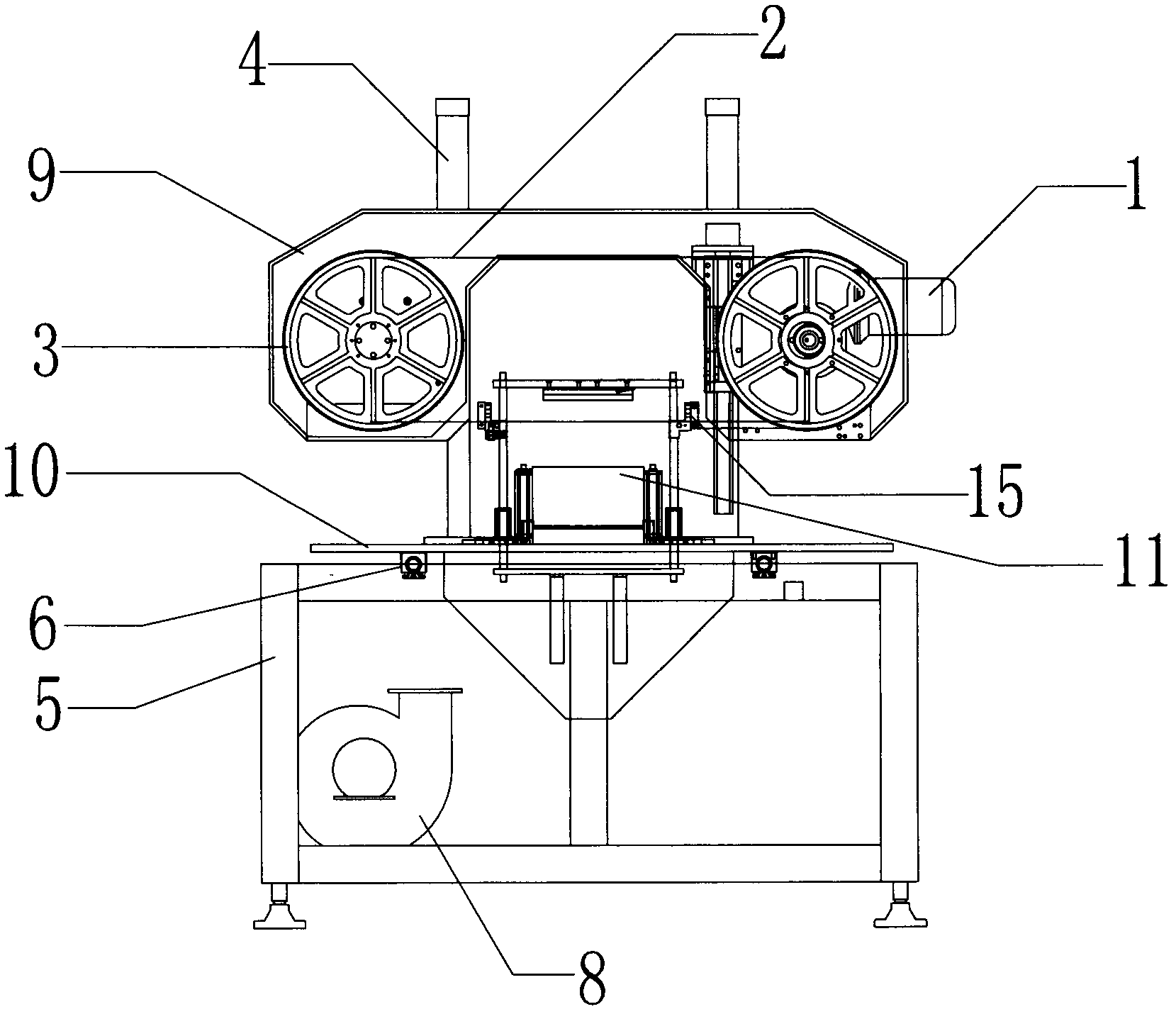

[0020] figure 1 , figure 2 A band saw cutting machine shown has a frame 5, the bottom of the frame 5 is provided with a dust suction system 8 and a hydraulic station 14 for controlling the overall hydraulic pressure, and the top of the frame 5 is provided with a feed liquid cylinder 4, and the feed liquid A saw frame 9 for fixing the saw disc 3 is arranged under the cylinder 4, a synchronous moving mechanism 6 for controlling the movement of the product 11 is arranged under the saw frame 9, and a main board 10 is arranged on the synchronous moving mechanism 6 for installing the cutting system and support product 11; in order to ensure that product 11 does not move on the main board 10, the clamping mechanism 7 for clamping product 11 is provided on the said synchronous moving mechanism 6; in order to make the synchronous moving mechanism 6 return to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com