Method of separating strengthened glass

A technology for strengthening glass and glass sheets, which is applied in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., and can solve problems such as multiple bifurcations and broken glass samples into multiple pieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A glass sample with the following composition was melted at 410°C in KNO 3 Soak in bath for 7 hours to allow ion exchange: 66.7 mol% SiO 2 ; 10.5 mol% Al 2 o 3 ; 0.64 mol% B 2 o 3 ; 13.8 mol% Na 2 O; 2.06 mol% K 2 O; 5.50 mol% MgO; 0.46 mol% CaO; 0.01 mol% ZrO 2 ; 0.34 mol% As 2 o 3 ; and 0.007 mol % Fe 2 o 3 . The thickness of the resulting ion exchange layer on the glass surface was about 50 microns.

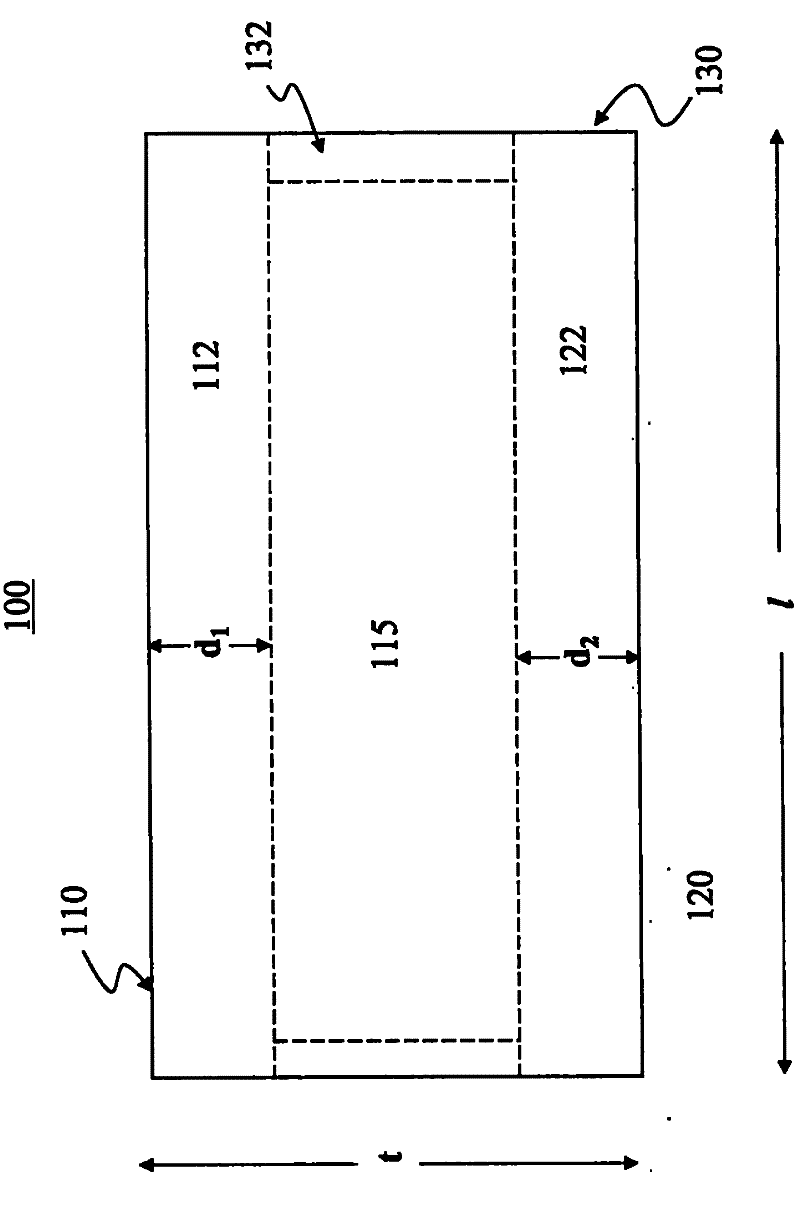

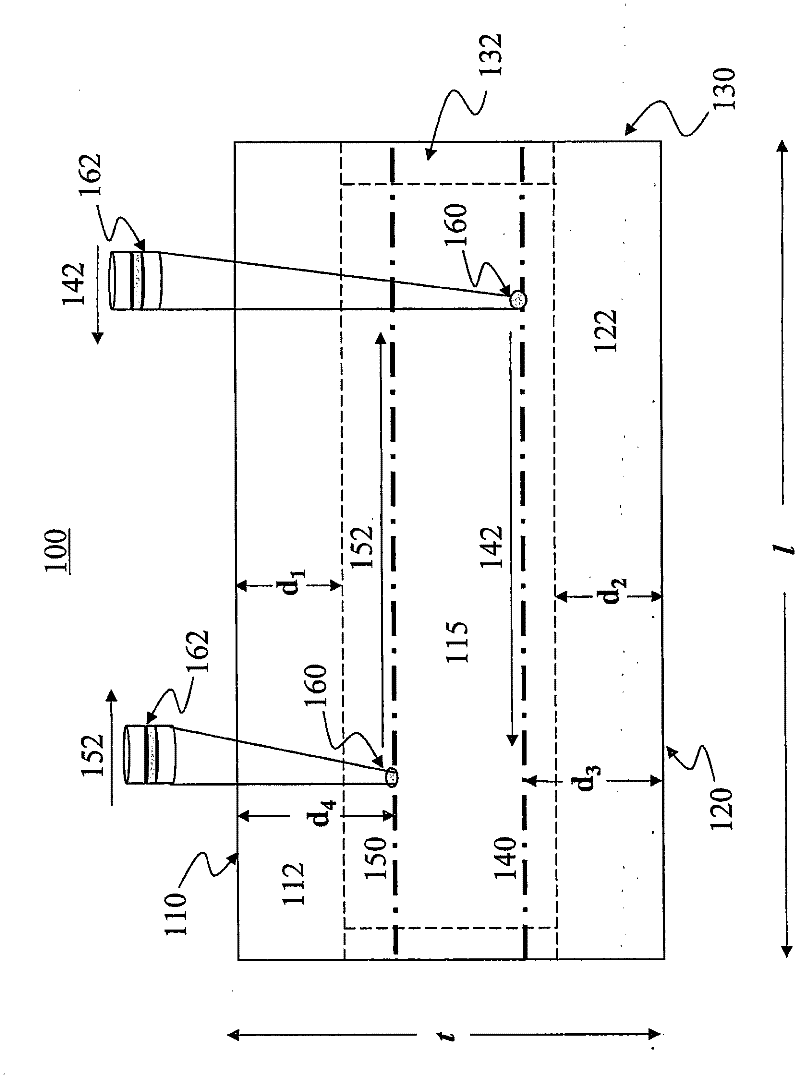

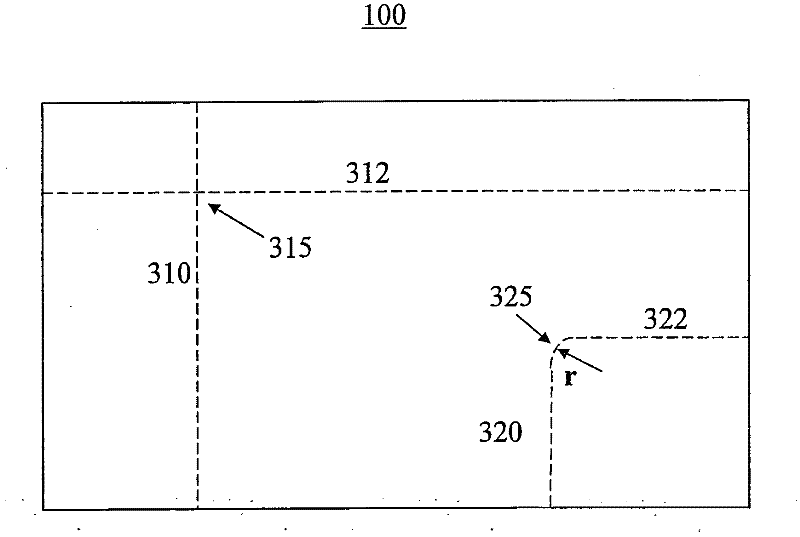

[0043] The glass sample was mounted on a computer-controlled XYZ frame moving at a speed of 30-300 mm / sec. First use a 0.27-NA lens to converge the output beam of the 355nm nanosecond Nd-YAG laser on the rear surface (i.e. the glass surface farthest from the laser, e.g. figure 1 and 2 50-100 microns above the second surface 120) in the center, converged into a light spot with a diameter of 1-3 microns. The average power of the laser beam is 1W, and the repetition rate is 150kHz. After writing the first break line near the rear surface, refocus the beam o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com