Electric leakage protection socket with discharge metal sheets

A leakage protection, metal sheet technology, applied in circuits, electrical components, parts of connecting devices, etc., can solve the problems of excessive material consumption, affecting discharge effect, and easy oxidation of discharge metal sheets, so as to reduce costs and improve lightning protection. Click effect, connection method is simple and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

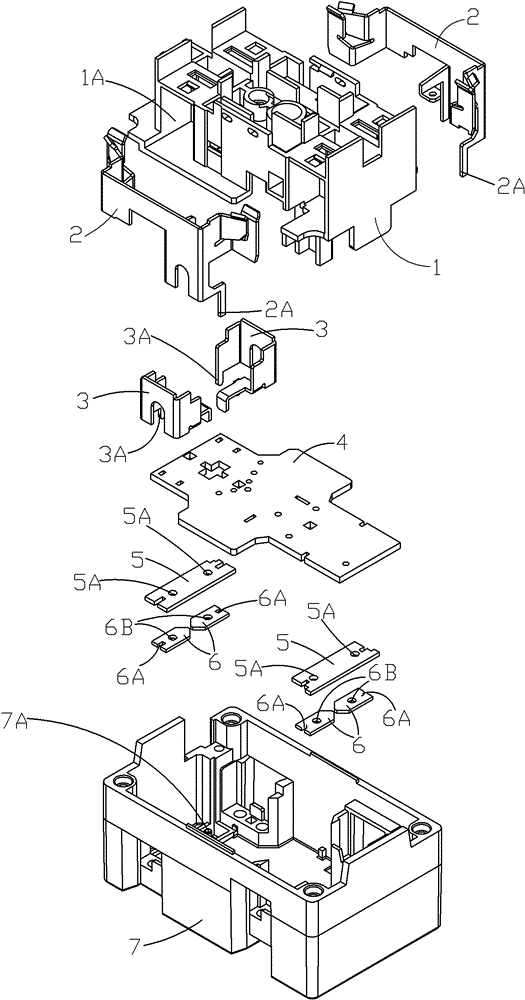

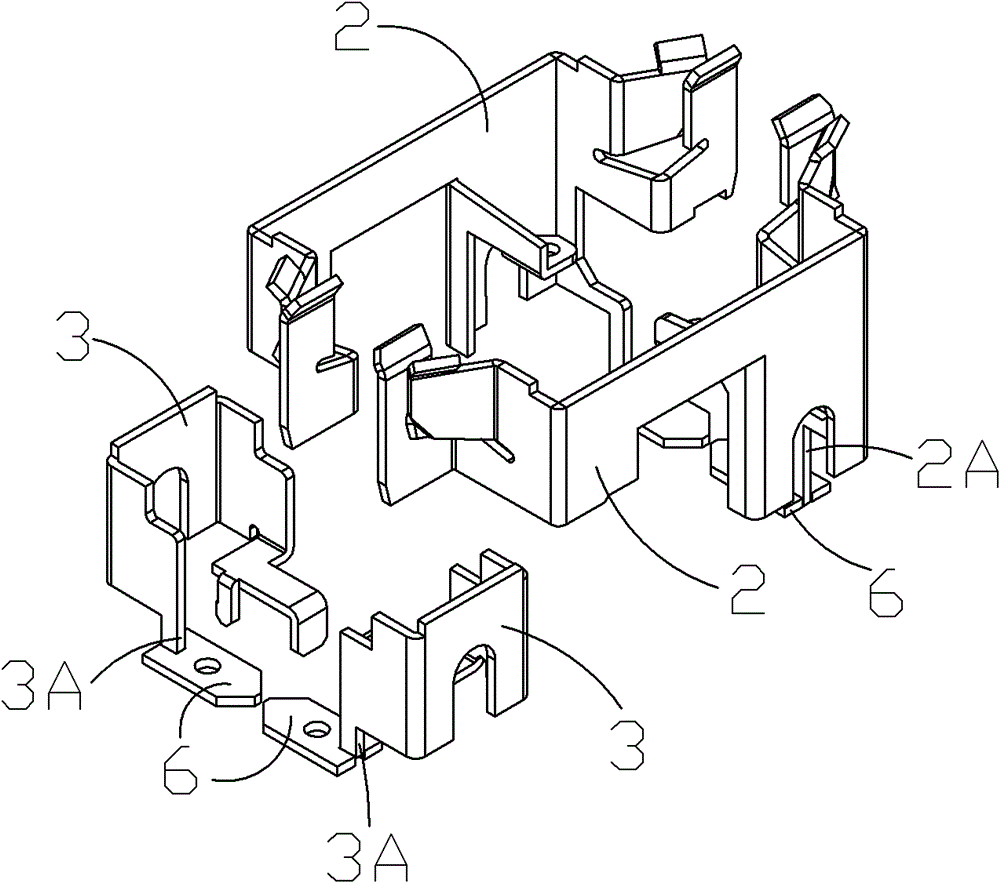

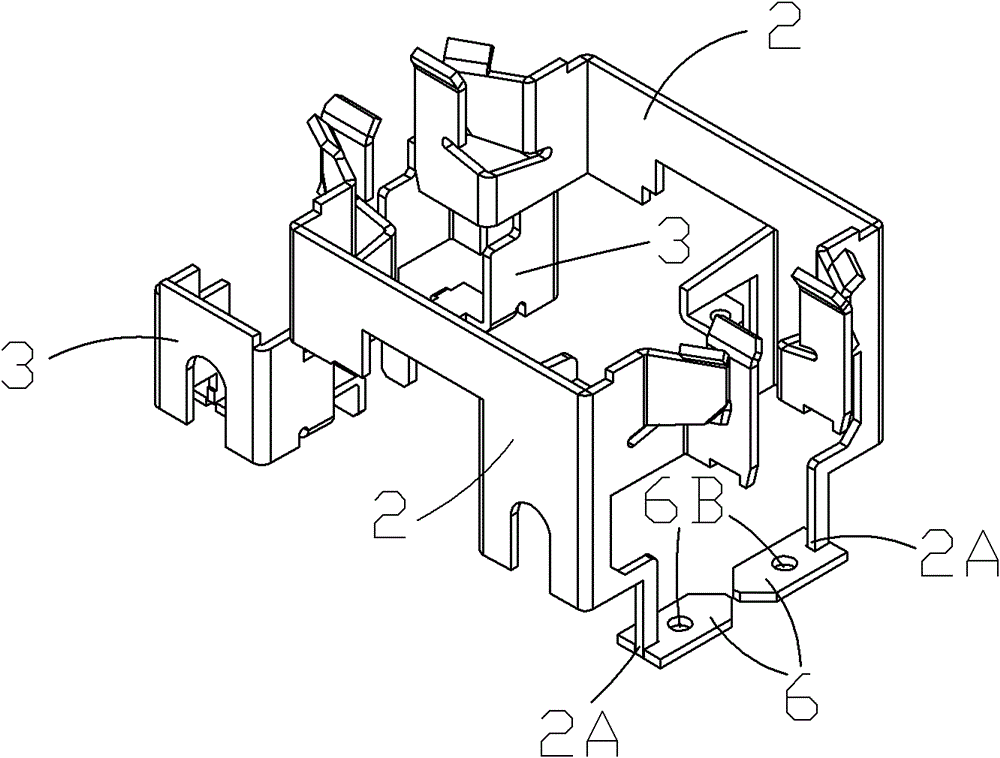

[0019] refer to Figure 1 to Figure 7 , a leakage protection socket with discharge metal sheets, including a housing (the housing includes an upper cover and a base, only the base 7 is shown in the figure), a pair of power input conductors 3, a pair of output conductors 2 with conductive sockets and The control circuit board 4 used to control the on / off between the input conductor and the output conductor, a pair of power input conductors 3 respectively have pins 3A, and a pair of discharge metal sheets 6 are correspondingly provided in the housing, and the discharge metal sheets have a The contact conductive position that the conductor conduction pin cooperates, the contact conductive position of this embodiment is the slot 6A that tail end is open, and two discharge metal sheets have discharge tip or discharge arc surface, and this embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com