Method for controlling heat-humidity ratio of air conditioning system and fixed heat-humidity ratio type surface cooler

An air-conditioning system, heat-humidity ratio technology, applied in heating and ventilation control systems, refrigerators, heating methods, etc., can solve problems such as loss of control, and achieve the effect of simplifying the automatic control system, improving comfort, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

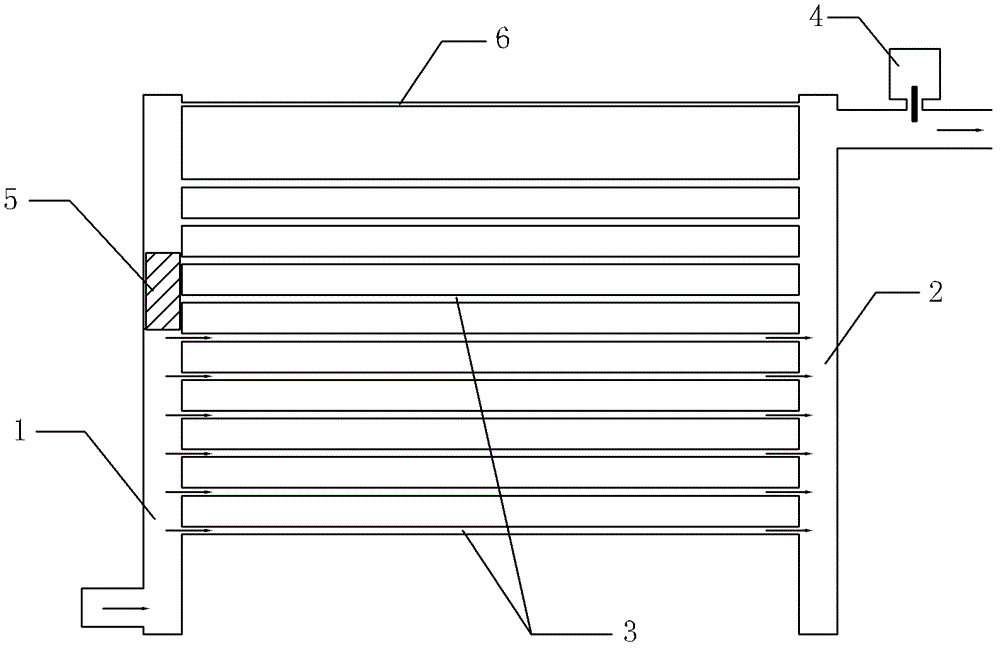

[0027] figure 1 and figure 2 Constitute the specific embodiment 1 of the present invention.

[0028] refer to figure 2 , the method for controlling the heat-humidity ratio of the air conditioning system described in this embodiment is characterized in that:

[0029] 1) Install a constant heat-humidity ratio surface cooler in the air-conditioning system, so that the air-conditioning system can block chilled water from flowing into non-essential coils through the piston when the air-conditioning system is under partial load, so as to limit the heat conduction of a part of the coils with a dominant proportion of sensible heat load ;

[0030] 2) Set a gravity piston and a pressure signal tube in the water supply main pipe of the constant heat-humidity ratio surface cooler, and control the pressure difference in the water supply main pipe of the constant heat-humidity ratio surface cooler through the gravity piston and pressure signal pipe The gravity piston is selected thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com