Greasing machine for automobile clutch diaphragms

A clutch and diaphragm technology, applied in mechanical equipment, engine components, engine lubrication, etc., can solve problems such as low production efficiency and affecting product quality, and achieve the effect of improving production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

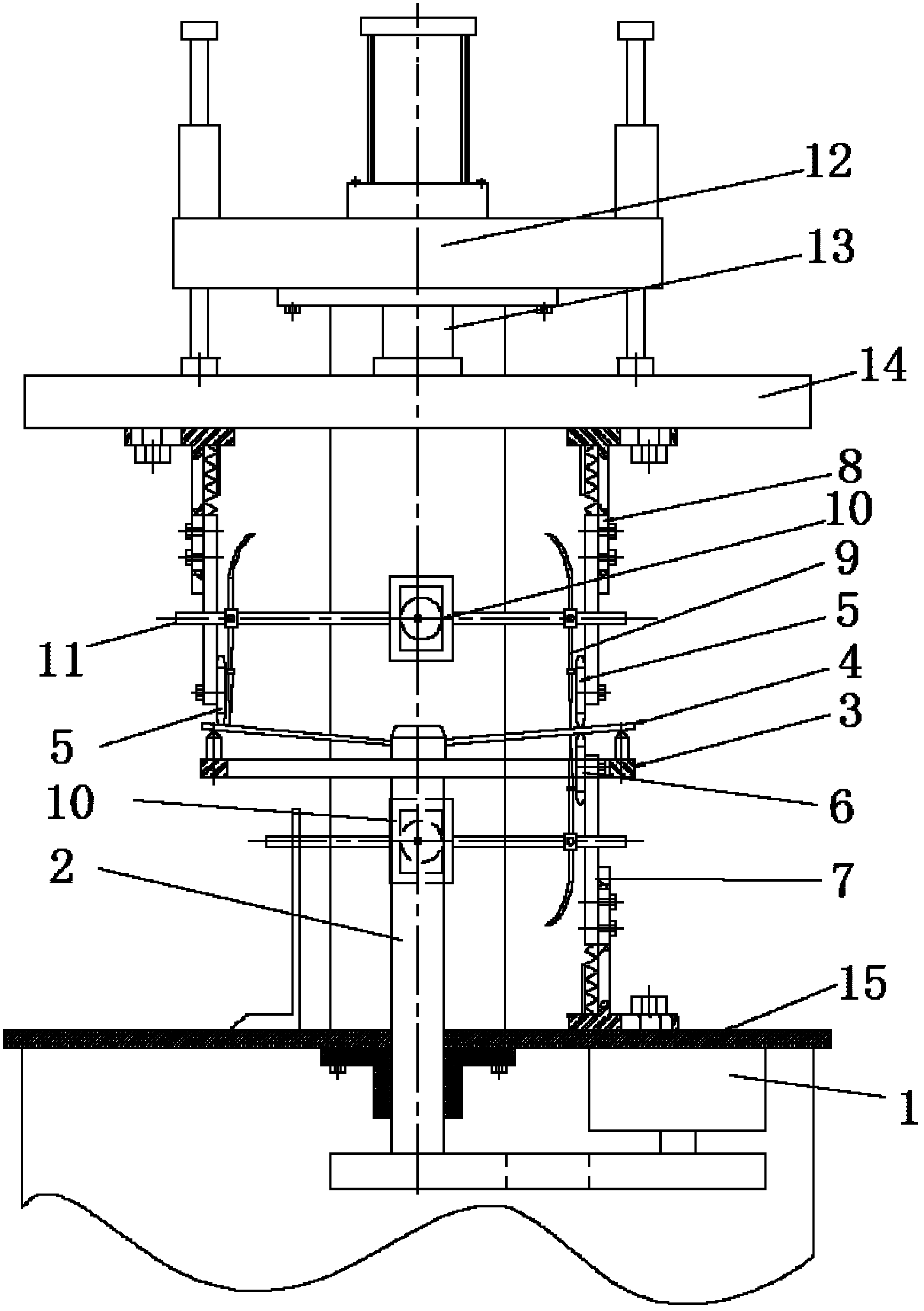

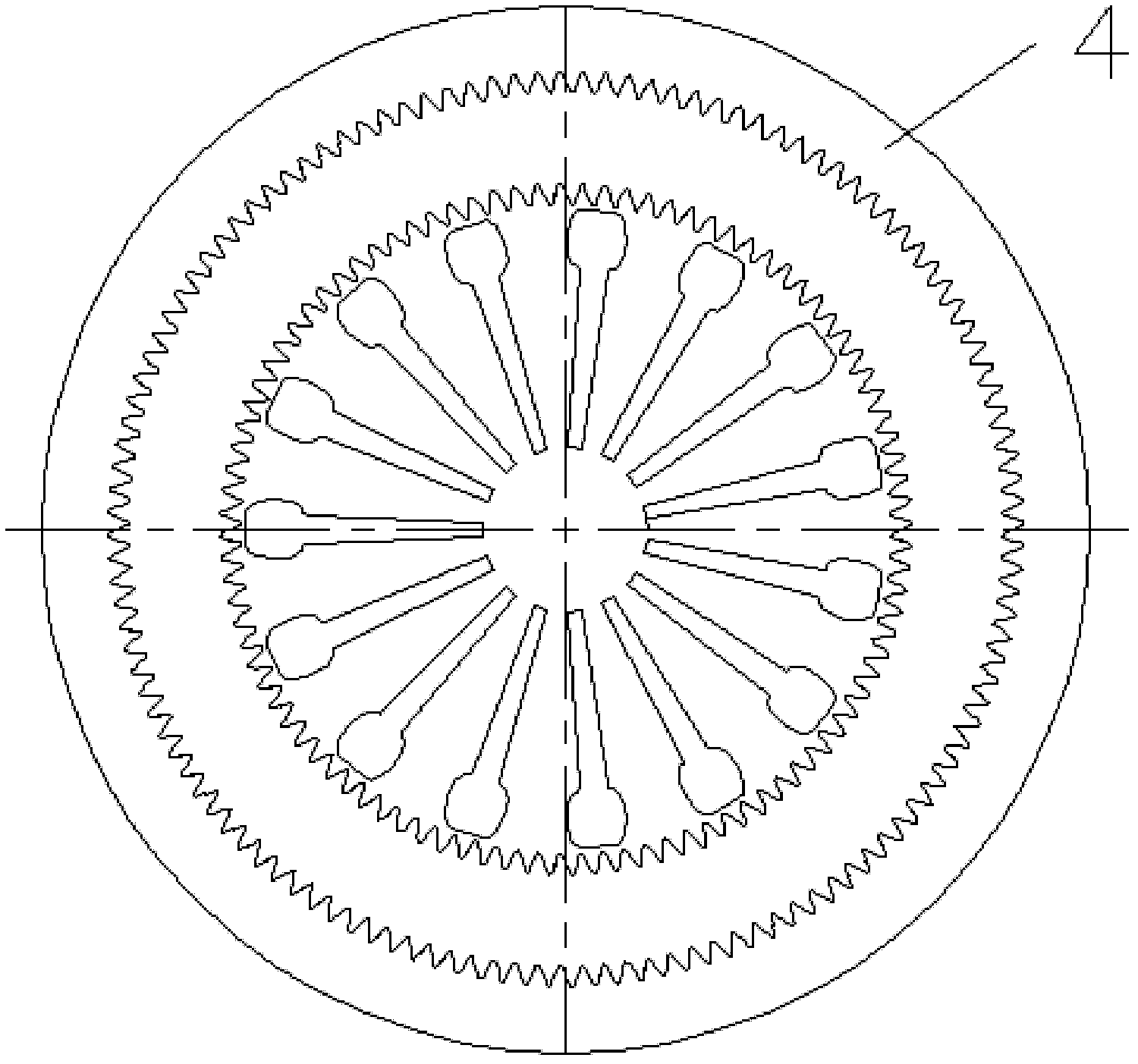

[0015] Such as figure 1 Shown a kind of grease coating machine for automobile clutch diaphragm, comprise the rotating shaft 2 that motor 1 controls to rotate, the rotary stage 3 that is driven to rotate by rotating shaft 2, the workpiece 4 that is arranged on the rotary stage 3, on the workpiece 4, The lower two sides are respectively provided with an upper pinch wheel 5 and a lower pinch wheel 6, and the lower pinch wheel 6 is connected with the lower pinch wheel bracket 7, and the upper pinch wheel 5 is connected with the upper pinch wheel bracket 8, and the upper pinch wheel 5 is connected with the upper pinch wheel bracket 8. The top of the tension wheel bracket 8 is connected with an up and down drive mechanism that drives it up and down, and the upper and lower sides of the workpiece 4 are respectively provided with fuel injection nozzles 9. Move on the swing bar 11. The up and down drive mechanism includes a support 12, a press table 14, and a cylinder 13 that drives t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com