Digital pressing platform

A platform and pressure technology, applied in the field of digital pressure platform, can solve the problems of large movement range of pressure platform, unfavorable paper feeding stability, large mechanical impact, etc., and achieve the effects of no mechanical impact, stable paper feeding, and adjustable contact time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

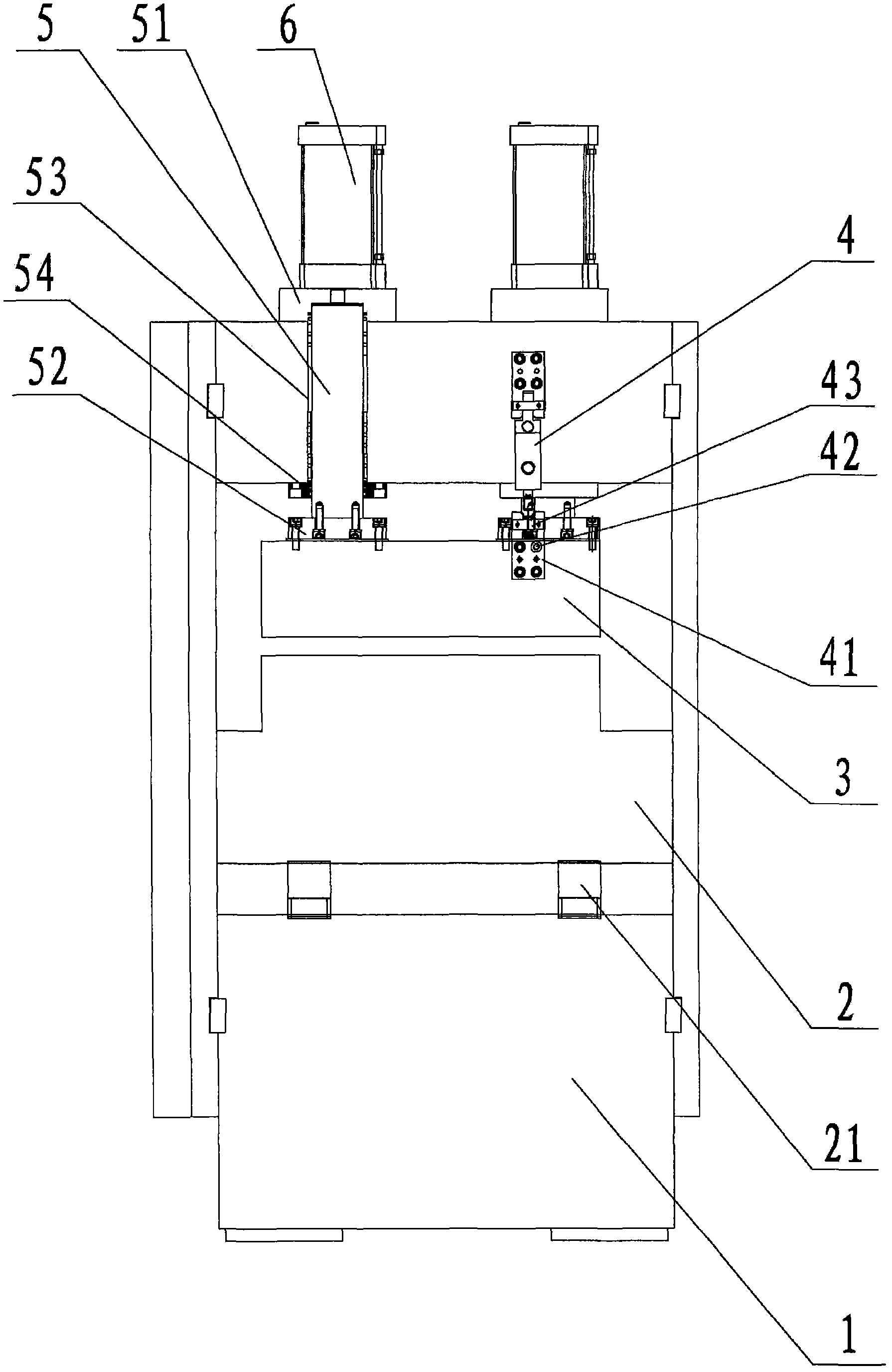

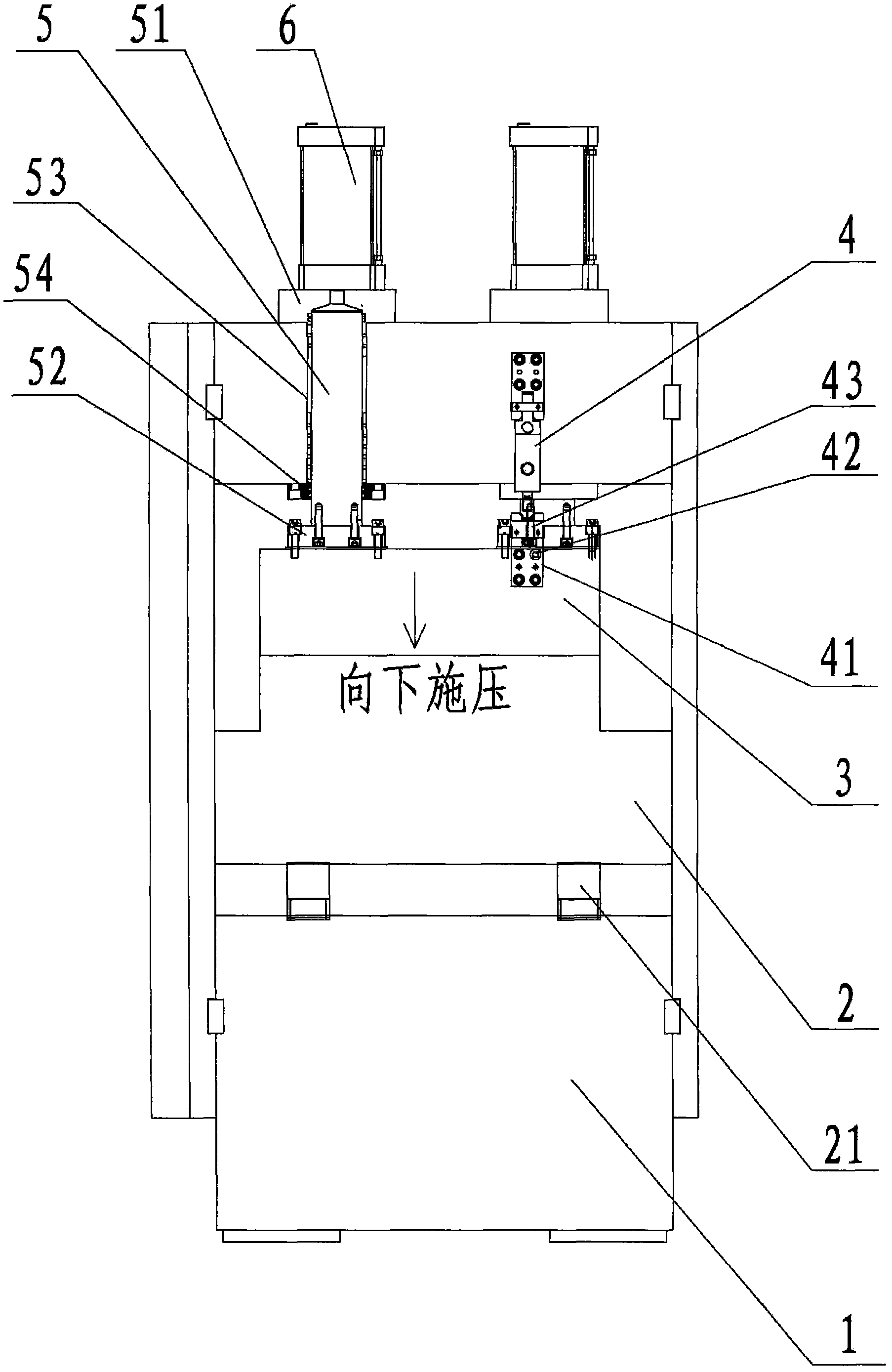

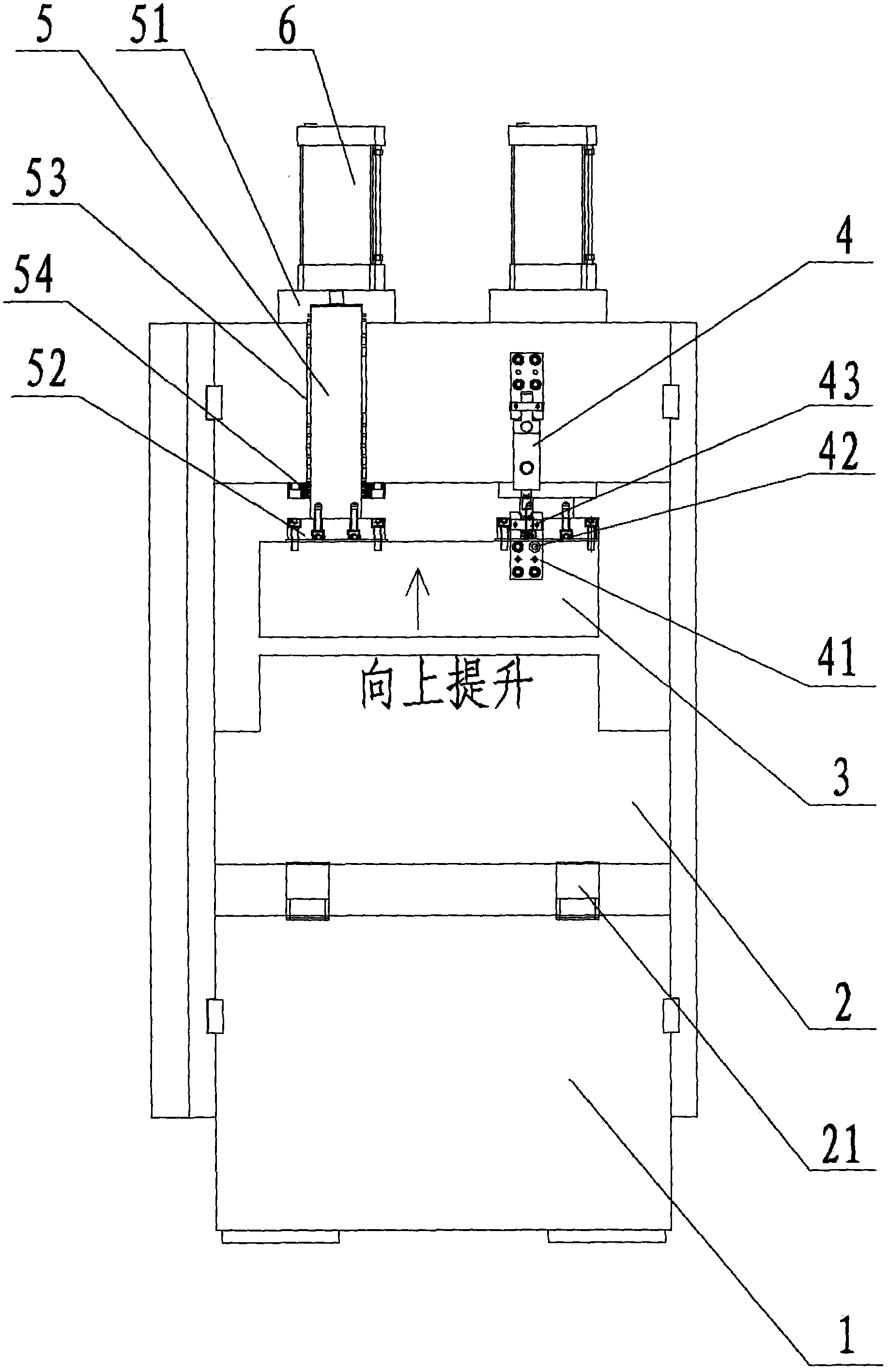

[0014] Please refer to the attached figure 1 to attach image 3 As shown, the present invention is a digital pressure platform, which is composed of base 1, lower static platform 2, upper moving platform 3, lifting device 4, hydraulic shaft 5, gas-liquid converter 6 and other components.

[0015] Wherein, the lower static platform 2 is installed on the base 1, and a pair of adjusting inclined irons 21 are arranged at the bottom of the lower static platform 2, and the pair of adjusting inclined irons 21 are used for finely adjusting the flatness of the lower static platform 2.

[0016] The upper moving platform 3 is located above the lower static platform 2 and the two are opposite to each other. The lifting device 4 is used to lift the pressed upper moving platform 3 upwards, and it is connected to the upper moving platform 3 by setting a connecting plate 41 , a pin shaft 42 and a joint bearing 43 . The lifting device 4 is specifically a lifting cylinder or a lifting cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com