End trimming device for automobile decorative strips

A technology of automobile decoration and trimming device, which is applied in the field of machinery, can solve the problems of aesthetic assembly, troublesome adjustment, low efficiency, etc., and achieve the effects of high trimming accuracy and reliability, stable mass production, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

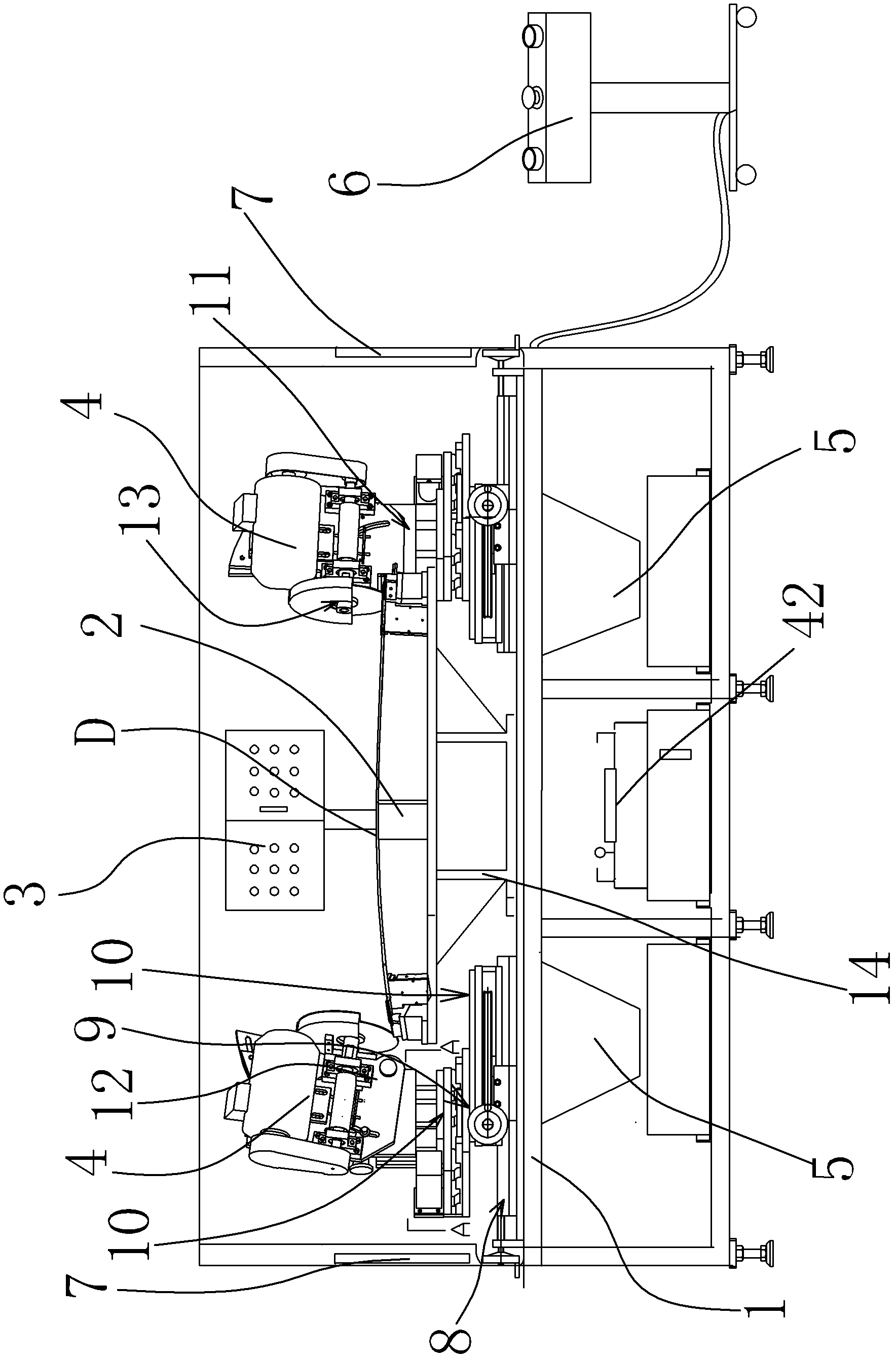

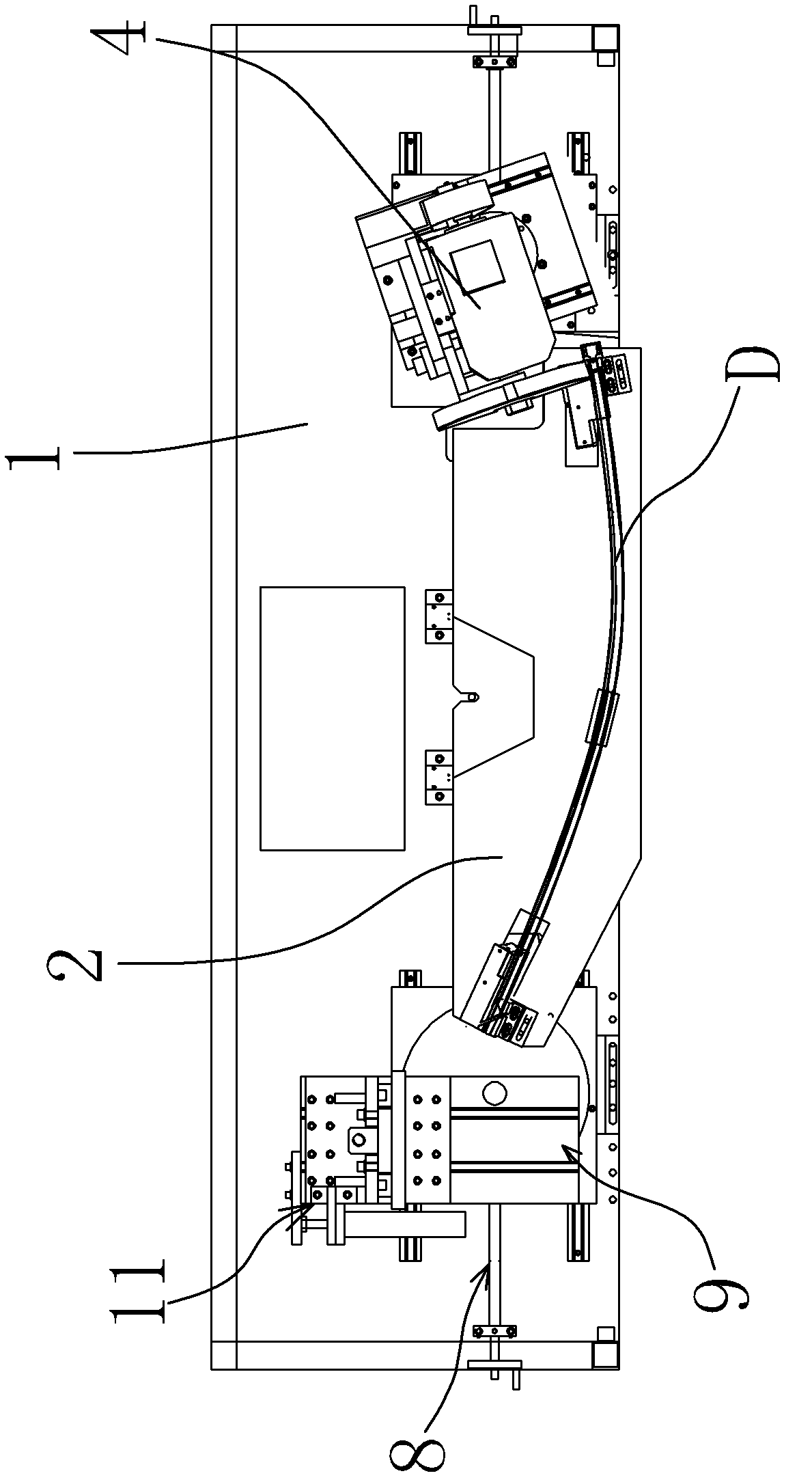

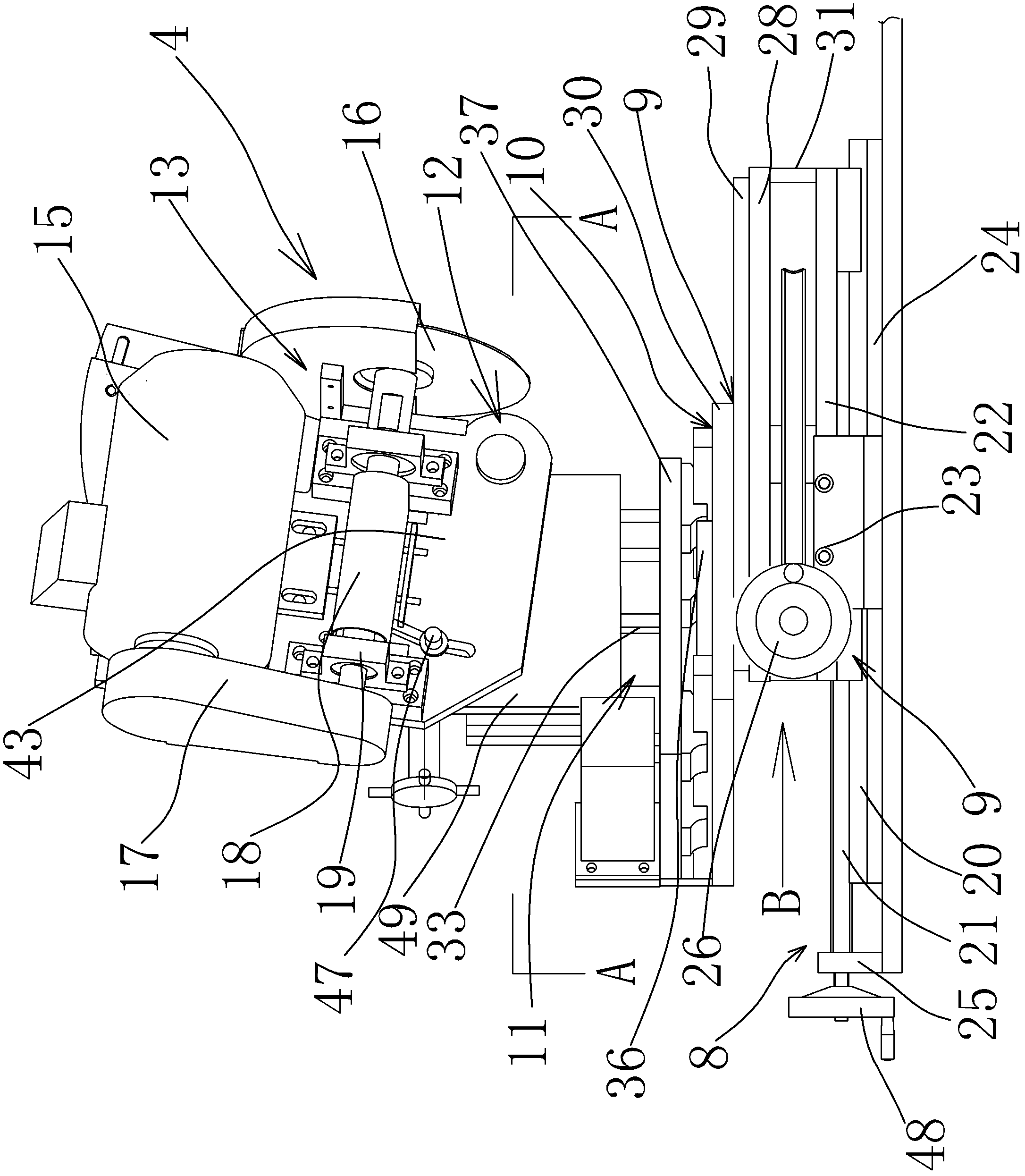

[0022] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0023] In the figure, frame 1; jig module 2; control box 3; trimming module 4; hopper 5; button console 6; light curtain 7; primary horizontal length adjustment mechanism 8; rotation adjustment mechanism 9; secondary horizontal length adjustment Mechanism 10; vertical adjustment mechanism 11; rotation adjustment mechanism 12; trimming mechanism 13; bracket 14; motor 15; trimming piece 16; transmission system 17; transmission shaft 18; transmission shaft support assembly 19; Lower guide rail slide plate 22; locking block 23; guide rail base plate 24; screw support plate 25; worm screw 26; worm wheel 27; Vertical adjustment screw 34; locking screw 35; upper guide rail 36; upper guide rail slide plate 37; oil cylinder 38; pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com