High temperature thermostatic bath of high capacity and high precision

A constant temperature bath, high-precision technology, applied in the direction of water bath/sand bath/air bath, etc., can solve the problems of limited temperature range, small working volume, low precision of constant temperature bath, etc., to avoid the influence of temperature fluctuation and enhance temperature uniformity The effect of widening the upper limit of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in further detail below in conjunction with accompanying drawing:

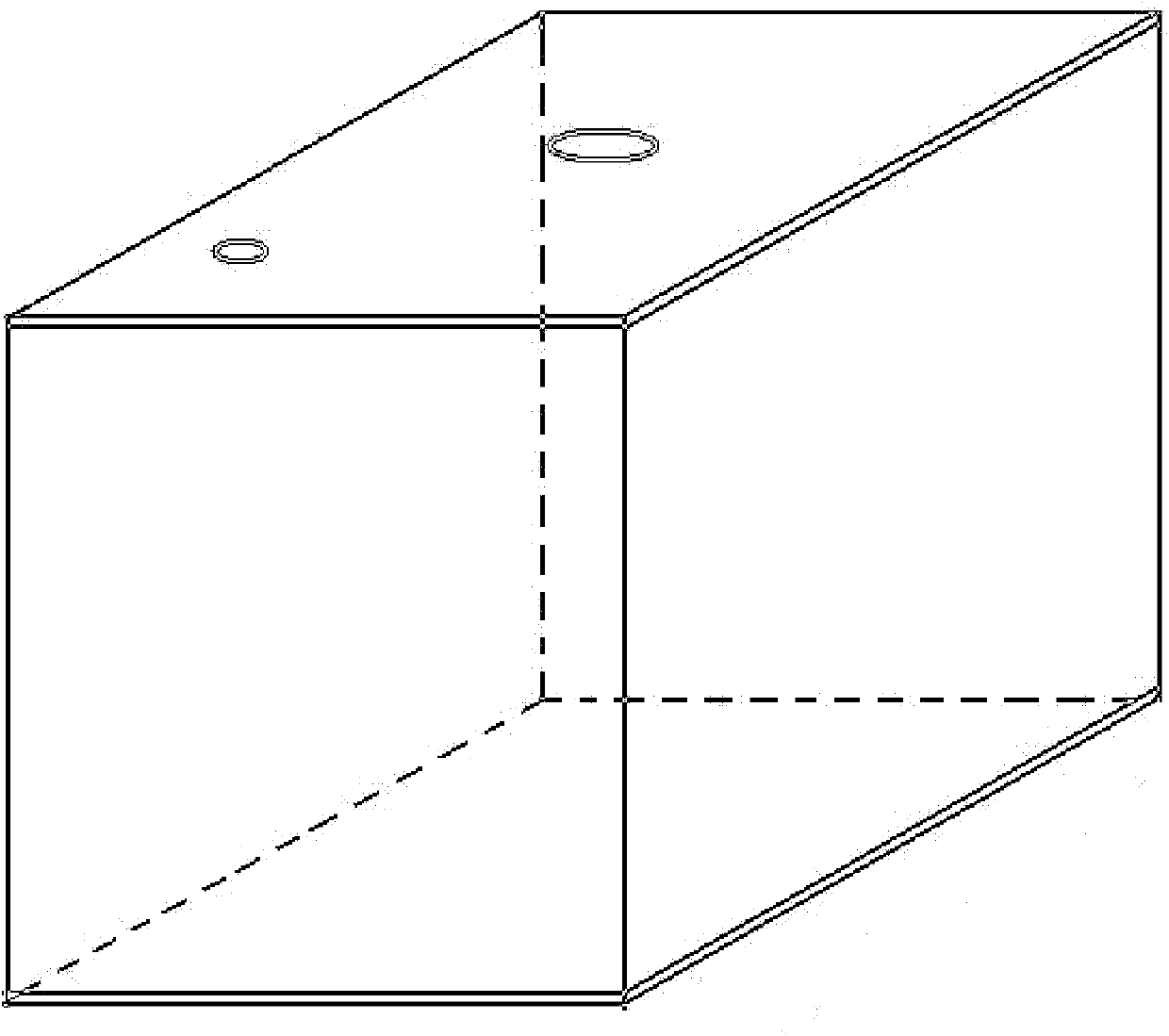

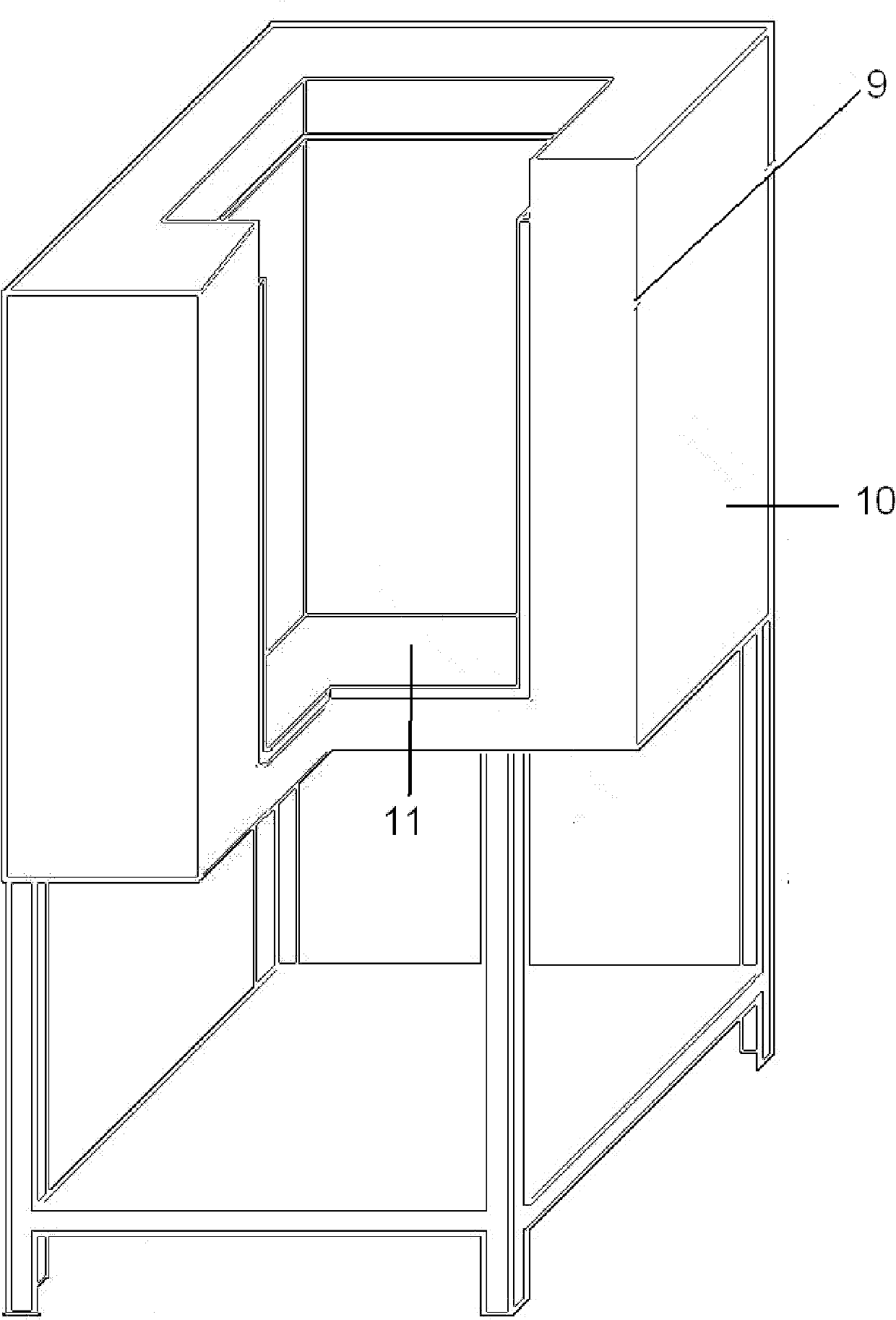

[0033] see figure 1 , 1 is the main body of the constant temperature tank, 2 is the insulation material, 3 is the precision platinum resistance thermometer, 4 is the temperature control unit, 5 is the temperature measuring instrument, 6 is the computer, 7 is the RS232 interface, 8 is the constant temperature medium. This new type of high-temperature constant temperature bath adopts the method of uniform heating on six sides to achieve the purpose of uniform temperature. The temperature control system will input the target temperature into the temperature control box, and the temperature control system will simultaneously control six heating plates to heat the constant temperature medium in the constant temperature tank. The temperature in the constant temperature tank is measured by a high-precision platinum resistance thermometer, and the measurement results are fed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com