Vacuum coating part and preparation method thereof

A vacuum coating and color layer technology, which is applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc., can solve the problems of low competitiveness of vacuum coating and achieve the effect of improving appearance competitiveness and enriching colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The vacuum coating part of the present invention can be an electronic device casing, and can also be a spectacle frame, a clock casing, a metal sanitary piece, and a construction piece.

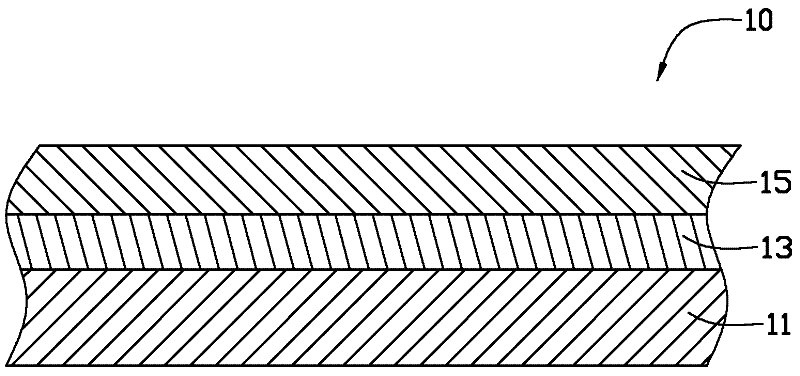

[0018] see figure 1 , the vacuum coating member 10 of the preferred embodiment of the present invention includes a base 11 , a base layer 13 and a color layer 15 . The base layer 13 is directly combined with the matrix 11 , and the color layer 15 is formed on the surface of the base layer 13 .

[0019] The material of the substrate 11 is aluminum alloy, magnesium alloy or stainless steel, preferably stainless steel.

[0020] The base layer 13 is formed between the base 11 and the color layer 15 to enhance the adhesion of the color layer 15 on the base 11 . The substrate layer 13 can be a titanium layer or other coatings that can provide adhesion. The thickness of the substrate layer 13 is about 0.05-0.2 μm, preferably 0.1 μm. The color of the base layer 13 is preferably a color tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com