On-line fault judgment and early-warning method for displacement sensor based on dynamic soft reduction

A displacement sensor and soft reduction technology, which is applied in the field of online judgment and early warning of displacement sensor faults under dynamic soft reduction, can solve problems such as the influence of billet quality, high manual labor intensity, and waste of materials, so as to prevent abnormal changes in roll gap, Improving the process control level and improving the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

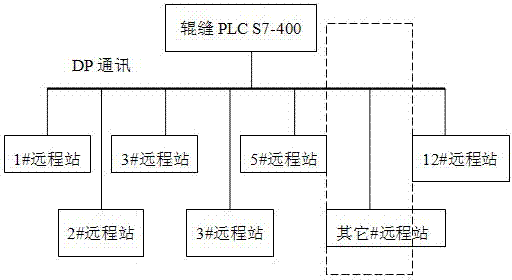

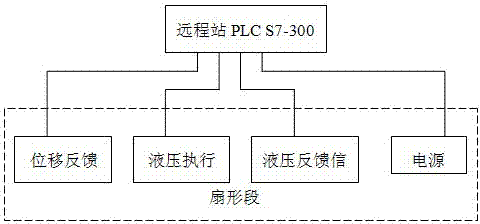

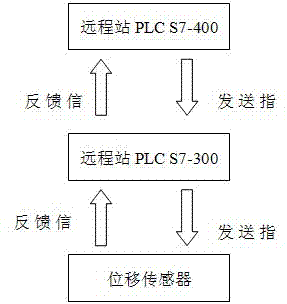

Method used

Image

Examples

Embodiment 1

[0020] Embodiment one: The feedback value of the sector displacement sensor fluctuates.

[0021] The "original number range" is 60,000 units between 0-60,000, and the "use range" is 80% of its "original number range", which is 48,000 units from 6,000 to 54,000; define the displacement sensor in PLC S7-400" "Overtravel Range" is 1% of "Used Range", set "Overtravel Range" to 480 units. When the effective range of the displacement sensor is 275mm, divide 275mm into 60,000 units, that is, the "overtravel range" is 1% of the "use range" 48000, which is 480 units (numerically equal to 2.75mm). The current actual roll gap value of the 7# segment is 43636 (equal to 220mm in value), and the feedback value is abnormal due to the fault of the displacement sensor, and 50181 (equal to 230mm in value) appears. PLC S7-300 feeds back this value to PLC S7-400 according to the original data transmission structure, and PLC S7-400 compares its data with the normal fluctuation value. After logi...

Embodiment 2

[0022] Embodiment two: The feedback value of the segment displacement sensor is zero.

[0023] The "original number range" is 60,000 units between 0-60,000, and the "use range" is 80% of its "original number range", which is 48,000 units from 6,000 to 54,000; define the displacement sensor in PLC S7-400" "Overtravel Range" is 1% of "Used Range", set "Overtravel Range" to 480 units. When the effective range of the displacement sensor is 275mm, divide 275mm into 60,000 units, that is, the "overtravel range" is 1% of the "use range" 48000, which is 480 units (numerically equal to 2.75mm). The current actual roll gap value of the 9# segment is 38749 (equal to 222mm in value). Due to the fault of the displacement sensor, the feedback value is abnormal, and the value of 0 appears. PLC S7-300 feeds back this value to PLC S7-400 according to the original data transmission structure, and PLC S7-400 compares its data with the normal fluctuation value. After logical operation, the dif...

Embodiment 3

[0024] Example 3: The feedback value of the segment displacement sensor remains unchanged.

[0025] The "original number range" is 60,000 units between 0-60,000, and the "use range" is 80% of its "original number range", which is 48,000 units from 6,000 to 54,000; define the displacement sensor in PLC S7-400" "Overtravel range" is 1% of "use range", which is 480 units, and "fine-tuning amount" is 0.3%, which is 160 units. The current actual roll gap value of 9# segment is 38749 (value is equal to 222mm). Due to the failure of the displacement sensor, the feedback value is abnormal, and the feedback value has been maintained at 38749. PLC S7-300 feeds back this value to PLC S7-400 according to the original data transmission structure, and PLC S7-400 compares its data with the normal fluctuation value. After logical operation, the difference between 38749 and 38749 is 0, which is lower than normal The "fine-tuning amount" 160 then judges that the clock line of the displacemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com