Frequency modulating linear motion transverse water current gravity ore dressing bed

A linear motion and gravity beneficiation technology, applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of unsatisfactory beneficiation effect, single horizontal water flow, and inconsistent force, etc., to achieve light and heavy minerals Fast stripping, improved processing capacity and enrichment ratio, and low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

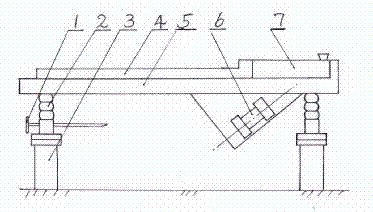

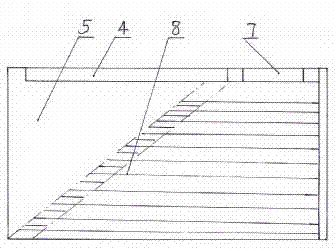

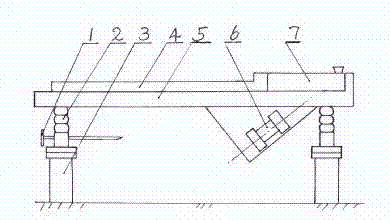

[0018] Such as Figure 1-2 Shown, sorting bed 5 is identical with existing shaking table, is provided with ore-feeding tank 7, flushing tank 4 and rifling bar 8 on the bed surface. According to different ore feeding properties, the rifling strips can be turned into grooves, or the rifling strips can be made into corresponding forms. Support 3 is also roughly the same with existing shaking table, all is to make four stakes with concrete, and spring 2 is four, and the lower end is installed on the support, and the upper end is fixed with the sorting bed. The spring is a general helical spring covered with a rubber sleeve.

[0019] The vibrator 6 is a commercially available product, and it is installed on the abdomen of the sorting bed near the end of the mine trough. When installing, first weld a seat plate or frame on the abdomen of the sorting bed, and then install the vibrator to the seat plate or frame go up. The vibration direction of the exciter coincides with or is par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com