Multifunctional threshing machine

A threshing machine, multi-functional technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of single function, inconvenient efficiency, large shedding, etc., and achieve the effect of improving threshing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

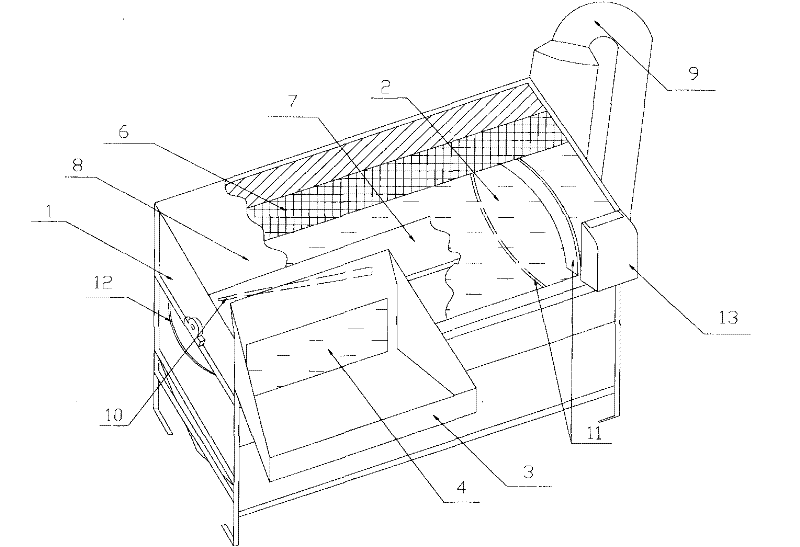

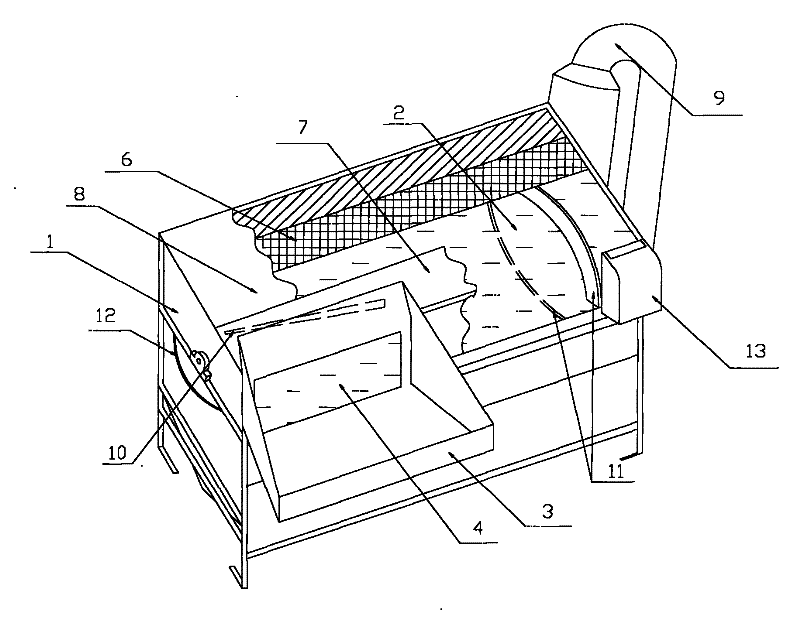

[0010] Example: see figure 1 , figure 2 , the present invention comprises a frame 1 open above, a feeding hopper 3, a separator 9, a slag outlet 13, a threshing drum 2 and a lower screen 5 below the threshing drum 2, the lower screen 5 is in a semicircular arc shape, The threshing drum 2 is evenly provided with a number of bow teeth, the feeding hopper 3 is fixedly connected to the front of the frame 1 near the left end, and the front of the frame 1 is provided with a through hole 4 communicating with the feeding hopper 3, and the lower sieve The net 5 is detachably connected with the frame 1, and the side of the frame 1 is provided with an arc-shaped gap 12 matched with the lower screen 5, and two slide rails are arranged in the frame 1, and the two slide rails are connected with the frame. 1 is fixedly connected and one end of the two slide rails is in communication with the arc-shaped gap 12, the lower screen 5 can be inserted into the chute through the arc-shaped gap 12,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com