Mould testing method for precise injection mould

An injection mold and precision mold technology, applied in the field of precision injection mold trial, can solve problems such as increasing costs, mis-trial and misrepairing of molds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

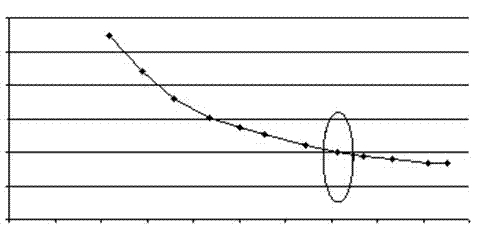

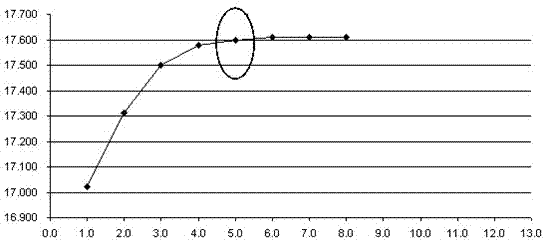

Image

Examples

Embodiment Construction

[0016] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

[0017] The invention provides a method for testing a precision injection mold, the steps of which are as follows:

[0018] Step 1. Mold water flow measurement Connect the water groups on the trial-manufactured precision molds, and confirm that the water flow is a path. If it is not a path, check the water flow group of the mold. If it is a path, use water pipes to measure the flow rate. The meter is connected in series to each group of water delivery of the precision mold, and the flow value of each group of delivery water is read separately. If the flow value is less than the set value, the water delivery group corresponding to the flow value is detected, otherwise, go to the next step;

[0019] Step 2. Get the reasonable injection speed of the injection molding machine

[0020] Step 2.1. Clamp the precision mold into the clampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com