Method for enlarging, filling and supporting coal-pillar-free mining roadway for fully-mechanized top coal caving

A technology for fully mechanized mining and caving without coal pillars, which is applied in the fields of backfill, mining equipment, earth-moving drilling and mining, etc., can solve the problems of inability to realize, large deformation of surrounding rock, and complicated filling construction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

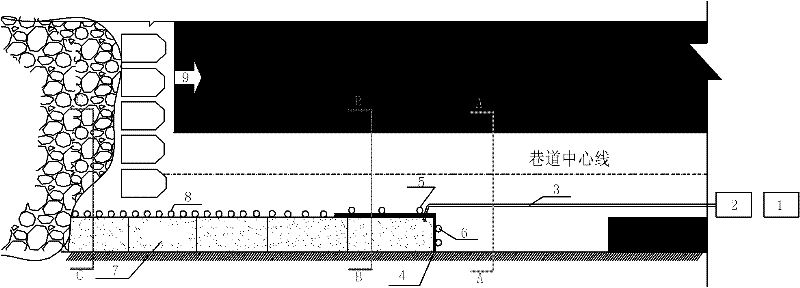

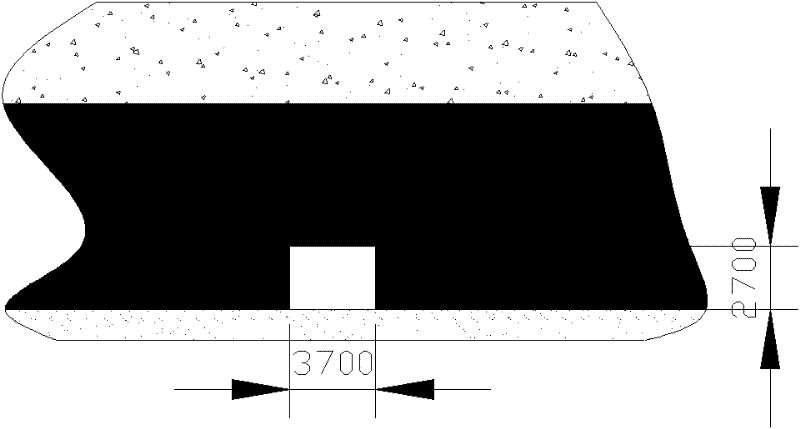

[0027] The present invention provides a method for expanding side filling and support for fully mechanized top-coal caving and non-coal pillar mining roadway. In order to make the purpose, technical scheme and advantages of the present invention clearer and clearer, the present invention will be further described below in conjunction with the accompanying drawings. Detailed description.

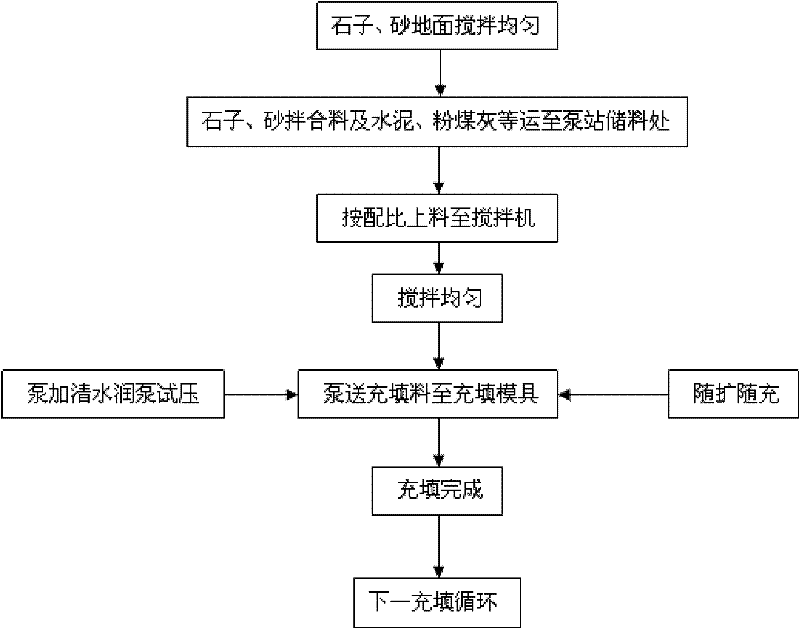

[0028] The invention provides a method for filling and supporting the side of a fully mechanized top-coal caving mining roadway without coal pillars. The concrete filling is produced by adding stones, sand, cement, fly ash and additives (early strength agents) and stirring them evenly with water. , through long-distance pumping to the filling mold, and filling as it expands, it realizes the integrated control technology of side expansion, filling and support, improves the coal recovery rate, reduces the maintenance cost of the roadway in the lower section and this section, and improves The op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com