Direction-adjusting device for open-type full-section hard rock tunneling machine

A hard rock roadheader and full-section technology, which is applied to mining equipment, earthwork drilling, tunnels, etc., and can solve problems such as complex structures of steering devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

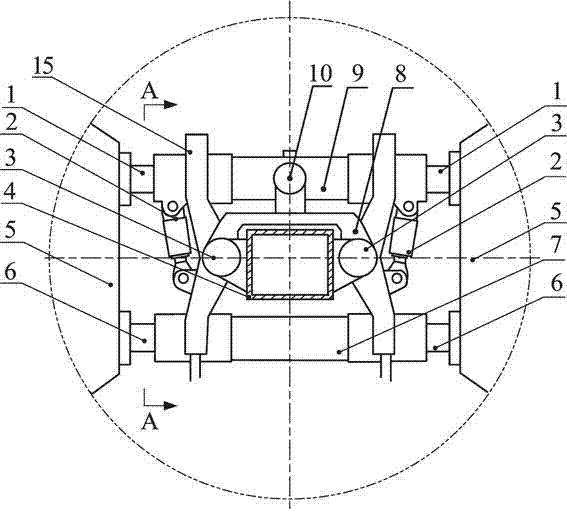

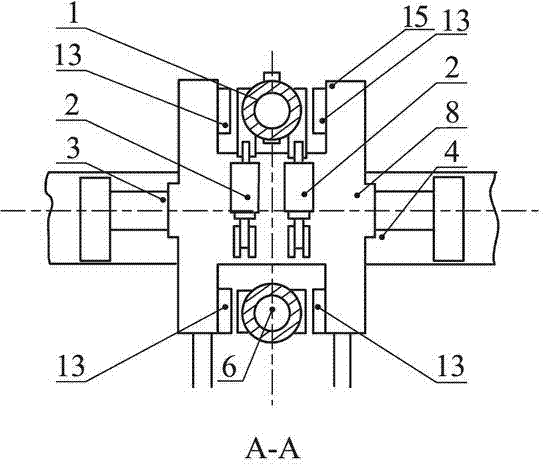

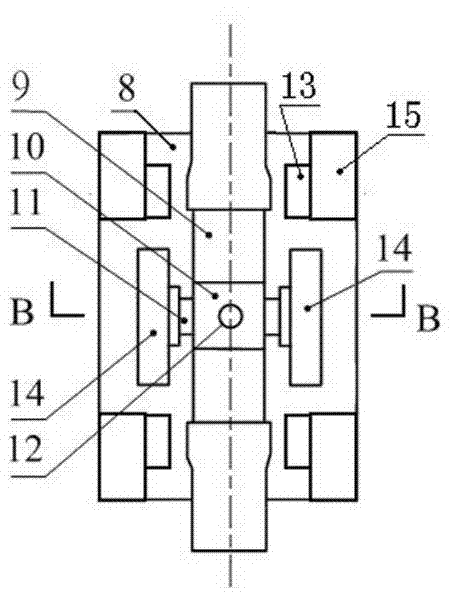

[0020] See Figure 1 to Figure 4 , an open-type full-section hard rock roadheader steering device, including a main beam 4 with guide rails 3 on both sides, two support shoes 5 and a saddle frame 8 located on both sides of the main beam 4, and each support shoe 5 passes through a spherical An upper shoe cylinder 1 and a lower shoe cylinder 6 are hinged, and an upper shoe cylinder shaft 9 and a lower shoe cylinder shaft 7 are respectively connected between the upper shoe cylinder 1 and the lower shoe cylinder 6 of the two shoes 5 The saddle frame 8 is installed on the guide rail 3, and can move forward and backward relative to the guide rail 3, and the two sides of each upper shoe oil cylinder 1 and the saddle frame 8 are hinged by the torque cylinder 2; the shaft 9 of the upper shoe oil cylinder is connected to the The saddles 8 are connected by a mutually rotating cross pin structure 10, and the cross pin structure 10 is connected by a movable pin 12 to the upper shoe cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com