Saccharopolyspora spinosa strain, application of saccharopolyspora spinosa strain and method for preparing spinosad

A technology of Saccharopolyspora spinosa and spinosad, applied in the field of preparation of spinosad, can solve the problems of no industrial application value, poor bacterial performance, etc., and achieve good industrial application value and spinosad capability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The method for preparing spinosad provided by the present invention comprises the following steps: fermenting Saccharopolyspora spinosa 3460 to obtain a fermentation liquid containing spinosad.

[0028] In a preferred embodiment, the method for preparing spinosad of the present invention comprises the following steps:

[0029] (a) fermenting Saccharopolyspora spinosa 3460 of the present invention, or its mutant strain, to obtain a fermentation broth containing spinosad;

[0030] (b) Isolating spinosad from the fermentation broth.

[0031] Preferably, the method of the present invention includes the following steps: before fermentation, seed culture is carried out to obtain seed culture liquid.

[0032] In a preferred embodiment, the isolation of spinosad is carried out by:

[0033] (a) the fermentation broth containing spinosad is mixed with an organic solvent;

[0034] (b) solid-liquid separation to obtain spinosad extract.

[0035] This method of directly mixing t...

Embodiment 1

[0112] (1) Shake flask fermentation

[0113] Put 40mL of fermentation medium into a 250mL Erlenmeyer flask and sterilize it for later use. Insert 4 milliliters of seed culture liquid into the bottle, carry out shaker fermentation culture, temperature is 28 ℃, shaker speed is 220rpm, cultivate 8 days, the relative humidity of fermentation environment is 56%, obtain about 35mL fermentation liquid.

[0114] Composition of the fermentation medium:

[0115] The final concentration of soluble starch is 60g / L,

[0116] The final concentration of glucose is 10g / L,

[0117] The final concentration of soybean meal powder is 30g / L,

[0118] The final concentration of corn steep liquor is 10g / L,

[0119] The final concentration of soybean oil is 5g / L,

[0120] The final concentration of calcium carbonate is 5g / L,

[0121] The pH value of the fermentation medium before digestion was 7.0.

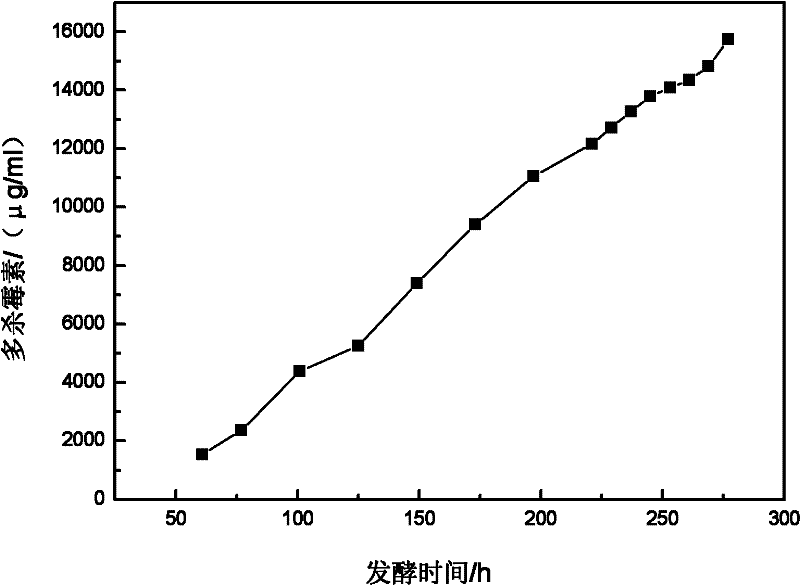

[0122] Make the growth curve of S. spinosa. The growth curve of S. spinosa figure 2 shown. ...

Embodiment 2

[0130] (1) fermentation

[0131] Shanghai Guoqiang FUS-50L automatic fermenter system was used for fermentation, the proportion of the medium was the same as that of Example 1, and the control process was as follows:

[0132] Table 1

[0133] control parameter

quantity

35L

temperature

28℃±0.5℃

Rotating speed

Starting at 400rpm, adjusted according to dissolved oxygen

Ventilation ratio

1∶1

0.05MPa

dissolved oxygen

The whole process> 40%

cycle

10 days

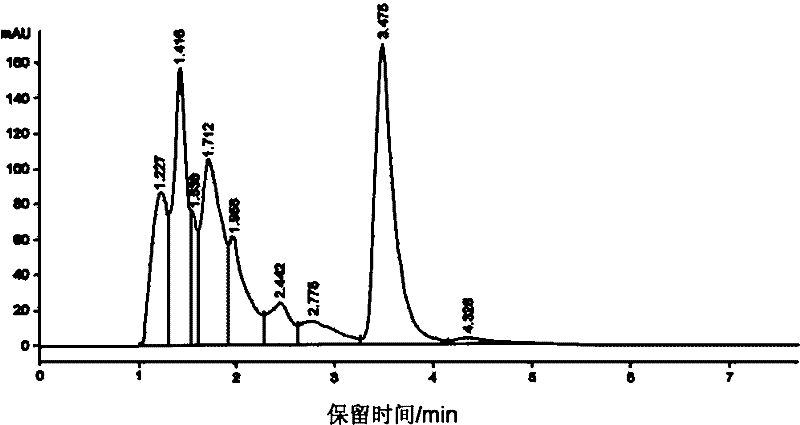

[0134] (2) extract spinosad

[0135] Solid-phase extraction method: take the following method to extract spinosad from the fermentation broth (solid-phase extraction method): take 1 mL of fermentation broth and carry out solid-liquid separation, discard the liquid, and obtain the spinosad-containing mycelium in a solid state , after drying the above-mentioned mycelium, 0.4 g of mycelium was obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com