Cleaning device

A technology of cleaning device and cleaning ring, which is applied to cleaning equipment, cleaning machinery, carpet cleaning, etc., can solve the problem of multiple cleaning of the mop, and achieve the effect of avoiding excessive humidity and reducing the frequency of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] The cleaning device of this embodiment includes: a water tank 1, a water roller 10, a water squeezing body 9, a cleaning endless belt 6, a first supporting roller 21, a second supporting roller 22, and two rollers 23. They are explained separately below.

[0098] 1. Describe and explain the water tank 1.

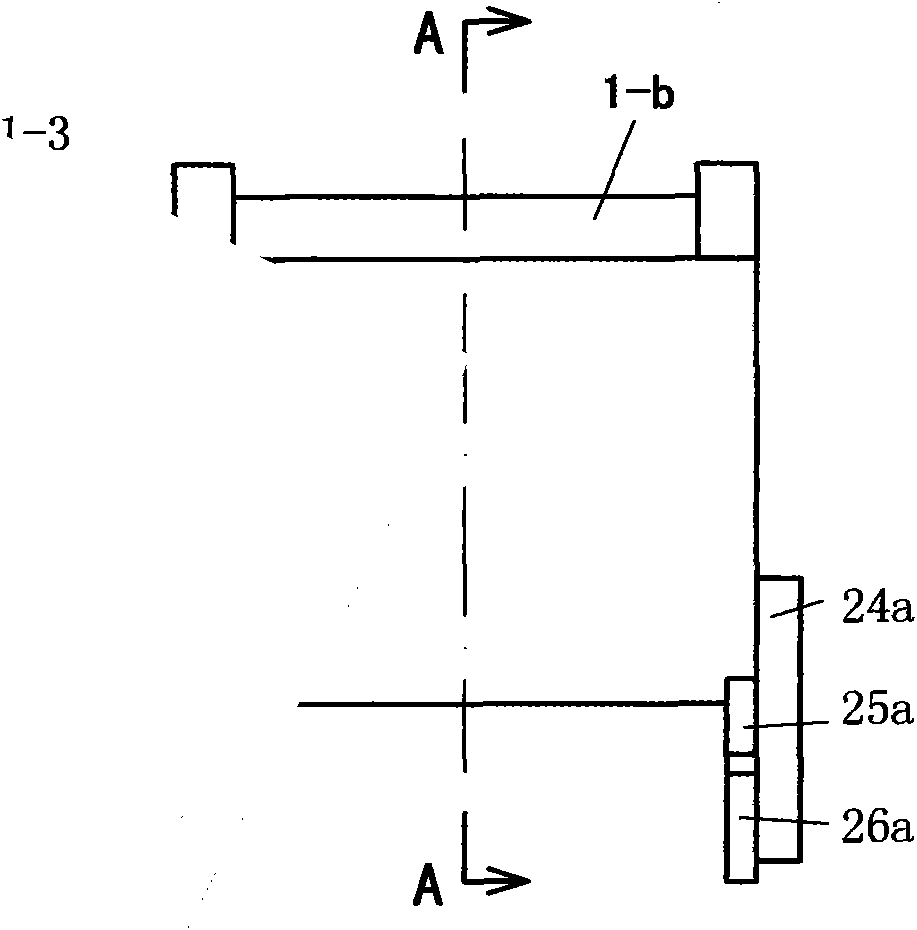

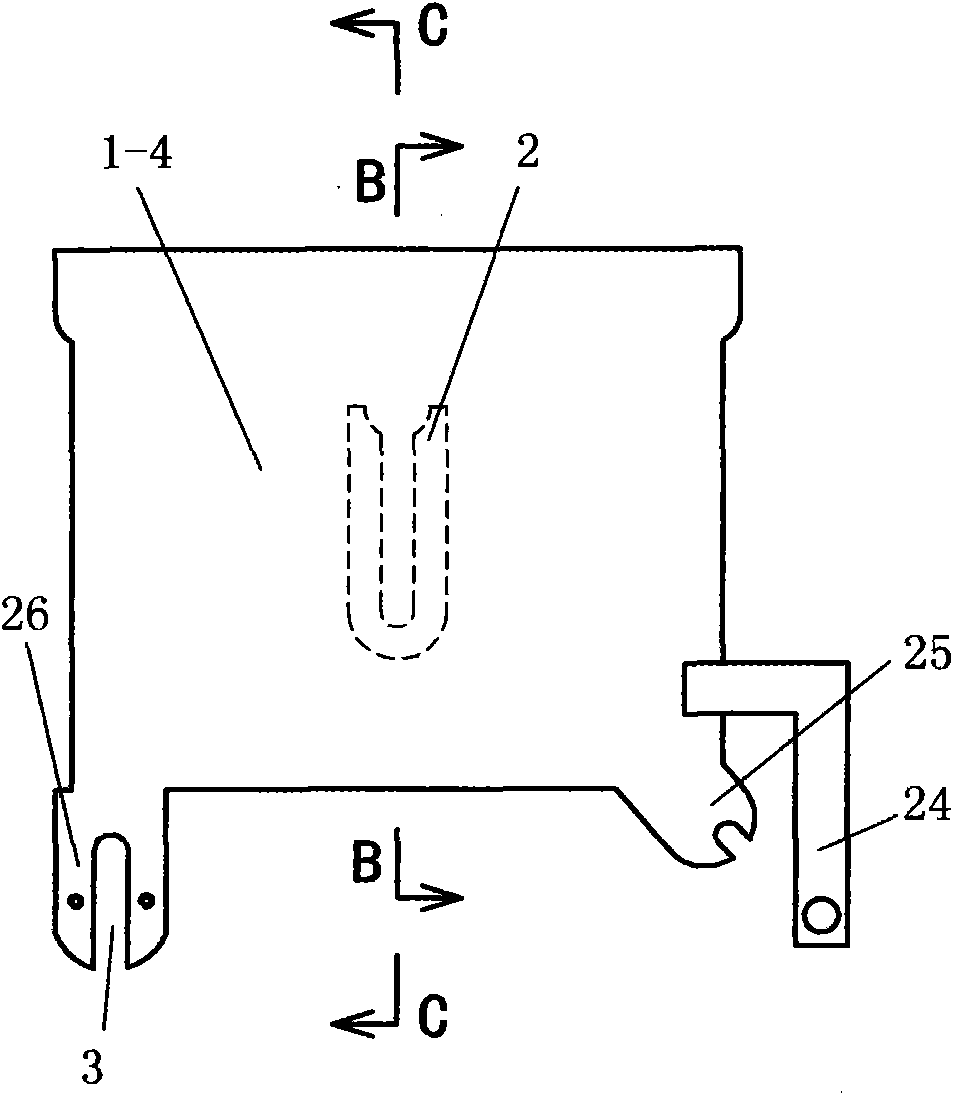

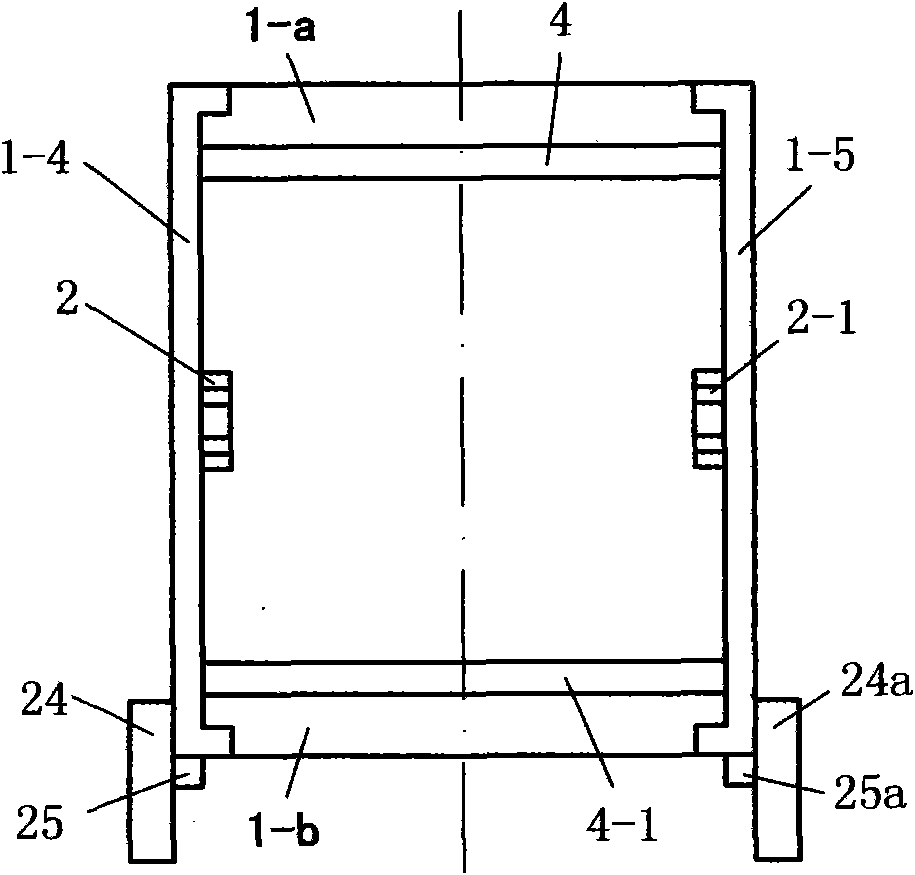

[0099] The water tank 1 has a bottom 1-1, a front wall 1-2, a rear wall 1-3, a left wall 1-4, a right wall 1-5, a first bracket 26, and a second bracket 25, such as Figure 1 to Figure 7 Shown.

[0100] The cross-sectional shapes of the front upper edge 1-a and the rear upper edge 1-b of the water tank 1 are arc-shaped; the front wall 1-2 of the water tank 1 is provided with an inwardly protruding horizontal front strip 4 with an arc-shaped protruding surface. The position of the horizontal front strip 4 corresponds to the position of the front squeezing piece 9-1; the rear wall 1-3 of the water tank is provided with an inwardly protruding horizontal rear strip 4-1 with an ...

Embodiment 2

[0129] In this embodiment, the water tank 1 is manufactured in an integrated manner using plastic as the raw material; the water tank 1 is as Figure 1 to Figure 10 Shown. figure 1 Is the main view of the water tank; figure 2 Yes figure 1 Left view of image 3 Yes figure 1 Top view of Figure 4 Yes figure 1 The rear view; Figure 5 Yes figure 1 A-A cross-sectional view; Image 6 Yes figure 2 B-B cross-sectional view; Figure 7 Yes figure 2 C-C cross-sectional view; Figure 8 It is a partial three-dimensional schematic diagram, expressing the situation of the bearing body on the left wall of the water tank; Picture 9 Is a three-dimensional schematic diagram of the cover; Picture 10 It is a partial three-dimensional schematic diagram of the water tank.

[0130] The water tank 1 in this embodiment has a bottom 1-1, a front wall 1-2, a rear wall 1-3, a left wall 1-4, a right wall 1-5, a first bracket 26, a second bracket 25, and a bearing Block 2.

[0131] The cross-sectional shap...

Embodiment 3

[0137] Using rubber or plastic as raw materials, the cleaning ring belt 6 is manufactured, and the manufactured cleaning ring belt 6 as a stand alone, before being installed on the device, presents a circular ring shape without seams.

[0138] In the present invention, the position of the cleaning endless belt 6 is: the front upper edge 1-a of the water tank 1, between the front wall 1-2 of the water tank 1 and the front squeezing sheet 9-1, the water roller 10 facing The lower surface, between the rear wall 1-3 of the water tank 1 and the rear squeeze sheet 9-2, the upper rear edge 1-b of the water tank 1, the surface of the second support roller 22, and the surface of the first support roller 21. The above position is like Picture 11 with Figure 13 Shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com