Direct driving type wind driven generator with double motors

A wind turbine, direct-drive technology, applied in wind turbine components, wind turbines, wind power generation, etc., can solve the problems of reducing the wind energy utilization rate of the generator, unable to adjust the output of the inner stator, and difficult to obtain wind energy utilization, etc. Improve axial space utilization, improve convenience, and reduce weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

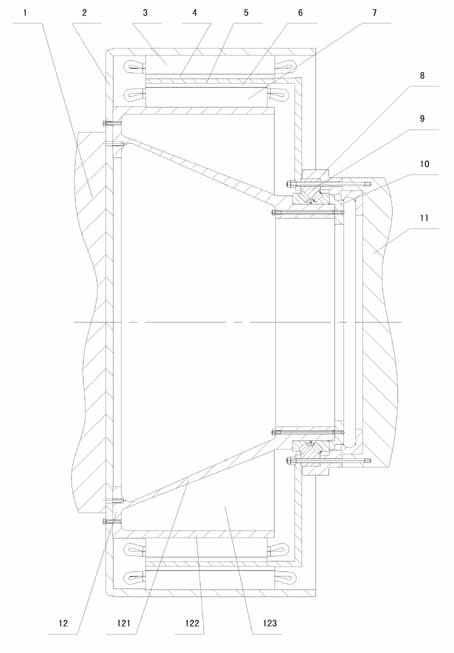

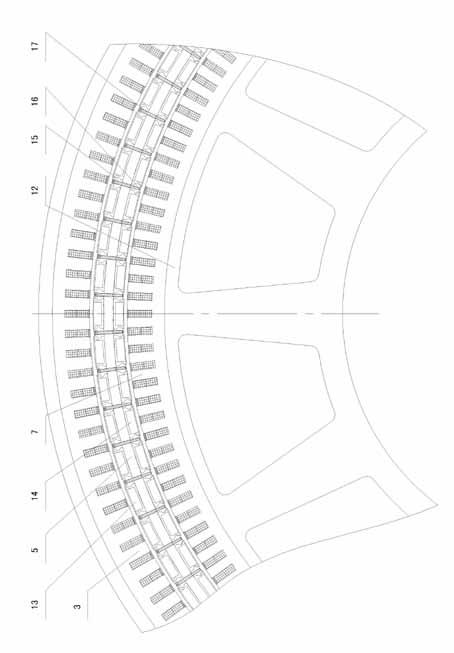

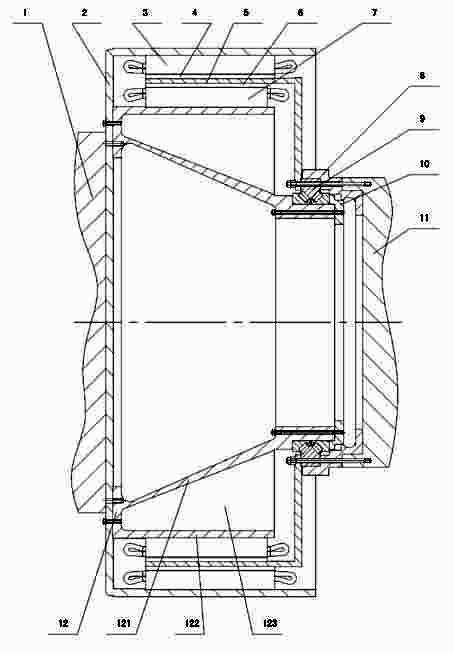

[0026] Depend on figure 1 and figure 2 The structure diagram of the shown dual-motor direct-drive wind power generator of the present invention can be known, and it comprises nacelle 1, machine base 2, impeller 11, main shaft 12, double stator and double rotor, and one end of described machine base 2 is connected with nacelle 1 connection, the double stators and double rotors are located in the base 2. The arrangement order of the double stators and double rotors from outside to inside is the outer stator 3 , the inner rotor 4 , the outer rotor 6 and the inner stator 7 . One end of the main shaft 12 is fixedly connected to the base 2 near the nacelle 1 , and the impeller 11 is rotatably connected to the other end of the main shaft 12 . The generator also includes a rotor support frame 5 , the rotor support frame 5 is fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com