Knitting cam for computer flat knitting machine

A computerized flat knitting machine and triangular technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve problems such as increased difficulty, high processing difficulty, complex structure, etc., and reduce production difficulty, production cost, and manufacturing process requirements Low, the effect of protecting economic interests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

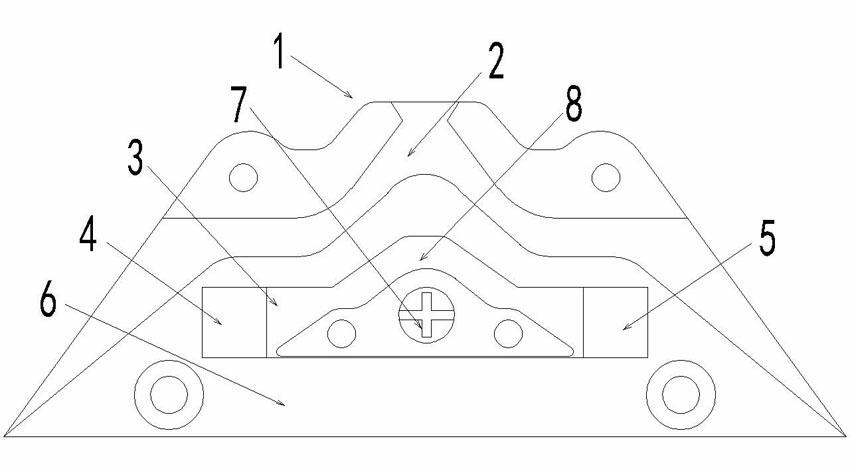

Embodiment 1

[0014] Embodiment 1: Referring to the accompanying drawings, the weaving cam 1 is left-right symmetrical, and its surface 6 has a weaving track 2. The surface of the weaving cam 1 has an inner cavity 3 between the weaving track 2 and the bottom edge. The inner cavity 3 is convex and has two ends. The first bevel 4 and the second bevel 5 smoothly transition to the surface 6 of the knitting cam 1, and the two sides of the top of the convex character of the inner cavity 3 are inclined to form an acute angle with the horizontal line respectively. Another guide block 7 that is also convex is threaded into the inner cavity 3, the two sides of the bottom end of the guide block 7 and the two sides of the top end are all inclined to form an acute angle with the horizontal line, and the bottom edge of the guide block 7 leans against the inner cavity The bottom edge of 3 can be seen from the figure, and the contact track 8 is formed between the guide block 7 and the top edge of the inner ...

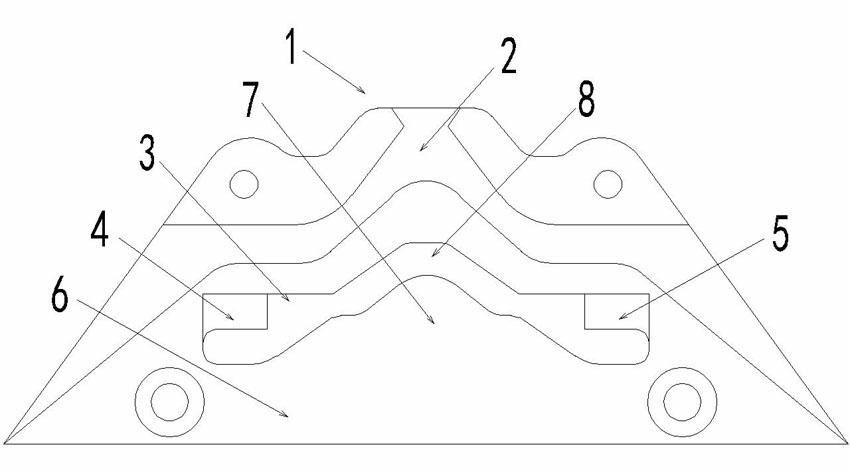

Embodiment 2

[0015] Embodiment 2: Different from Embodiment 1, the guide block 7 is connected with the braiding cam as a whole.

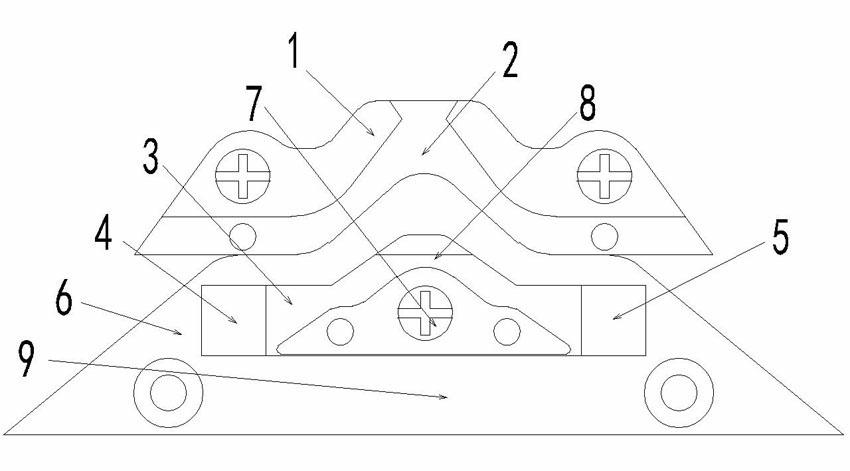

Embodiment 3

[0016] Embodiment 3: Different from Embodiment 1, the knitting triangle is divided into upper and lower parts, bounded by the bottom edge of the weaving track 2, the upper part is the weaving track block 1, and the lower part is the needle track block 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com