High-viscosity dispersion-resistant grouting material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

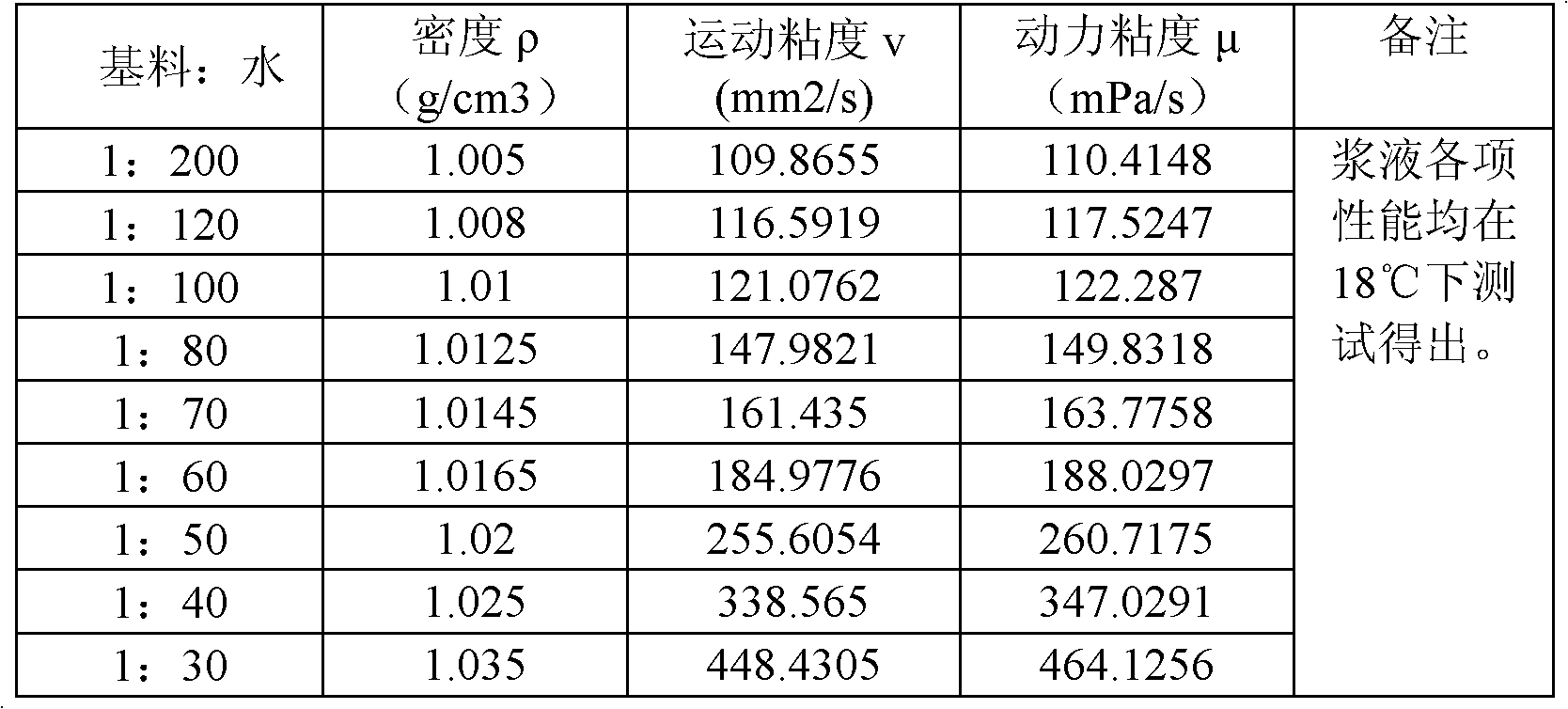

[0022] The high-viscosity anti-dispersion grouting material is prepared from polyacrylamide base material, water and dyeing agent. The mass ratio range of polyacrylamide base material to water is 1:30, and the mass ratio of dyeing agent to water is 1:100. The dyeing agent is made by mixing polyacrylamide solution and poinsettia solution at a mass ratio of 1:1 and then drying; the mass ratio of polyacrylamide and water in the polyacrylamide solution is 1:8; the mass ratio of poinsettia and water in the poinsettia solution is 1:2. (Poinsettia is actually acid fuchsin, molecular weight: 566.48)

[0023] Preparation method: first mix polyacrylamide and dyeing agent evenly, then sprinkle the mixed material into water evenly while stirring, let stand for 5-10 minutes to fully dissolve the base material, and re-stir evenly to complete the preparation of the slurry.

[0024] During the slurry preparation process, the materials must be evenly sprinkled while stirring to avoid the form...

Embodiment 2

[0026] The high-viscosity anti-dispersion grouting material is prepared from polyacrylamide base material, water and dyeing agent. The mass ratio range of polyacrylamide base material to water is 1:100, and the mass ratio of dyeing agent to water is 1:300. The dyeing agent is made by mixing polyacrylamide solution and poinsettia solution at a mass ratio of 1:1 and then drying; the mass ratio of polyacrylamide to water in the polyacrylamide solution is 1:10; the mass ratio of poinsettia to water in the poinsettia solution is 1:4.

[0027] Preparation method: Example 1 at the same time.

Embodiment 3

[0029] The high-viscosity anti-dispersion grouting material is prepared from polyacrylamide base material, water and dyeing agent. The mass ratio range of polyacrylamide base material to water is 1:200, and the mass ratio of dyeing agent to water is 1:200. The dyeing agent is made by mixing polyacrylamide solution and poinsettia solution at a mass ratio of 1:1 and then drying; the mass ratio of polyacrylamide to water in the polyacrylamide solution is 1:10; the mass ratio of poinsettia to water in the poinsettia solution is 1:3.

[0030] Preparation method: Example 1 at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com