Soy sauce filling machine

A filling machine and soy sauce technology, applied in packaging, bottle filling, liquid bottling, etc., can solve the problems that the internal pressure value of the material tank deviates from the predetermined range, the lifting displacement is difficult to accurately control, and the structure is complicated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

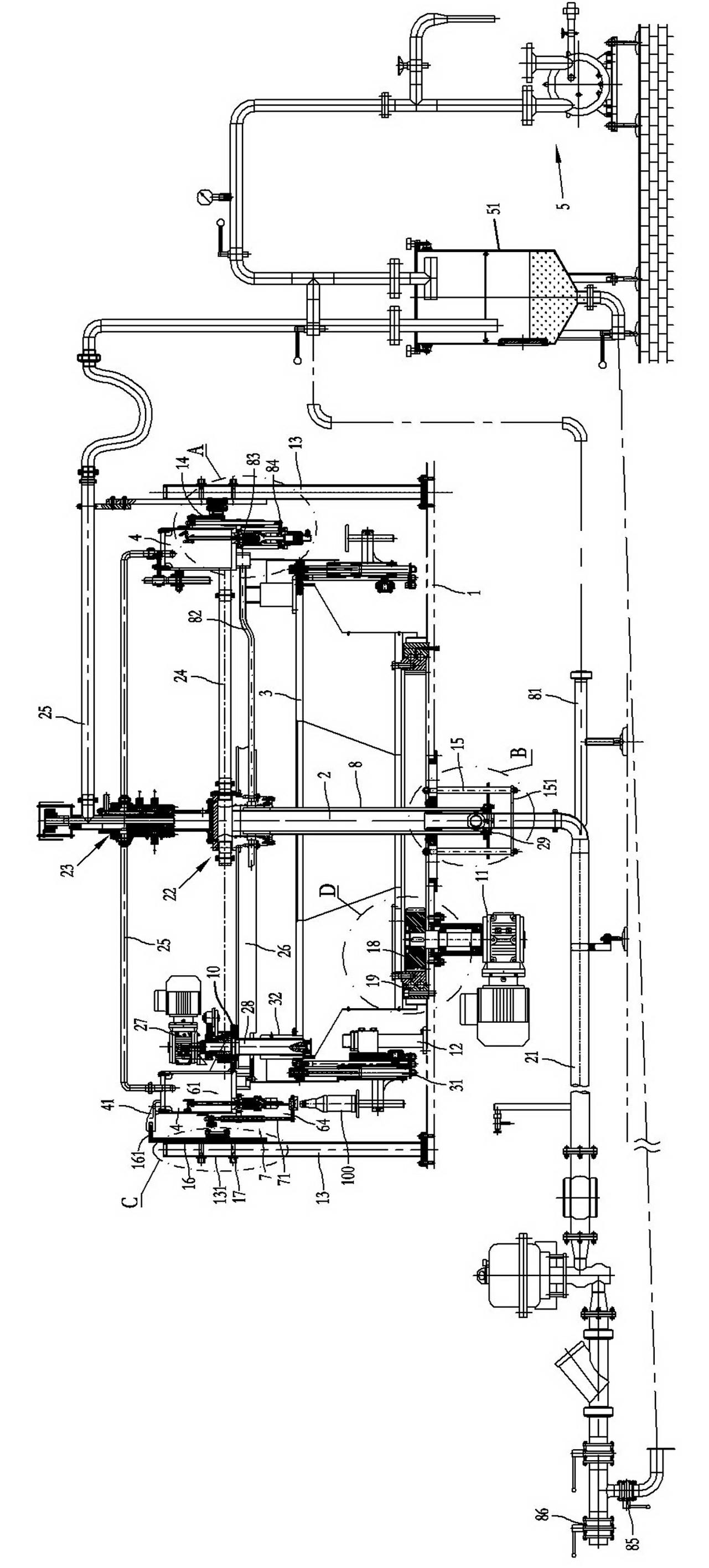

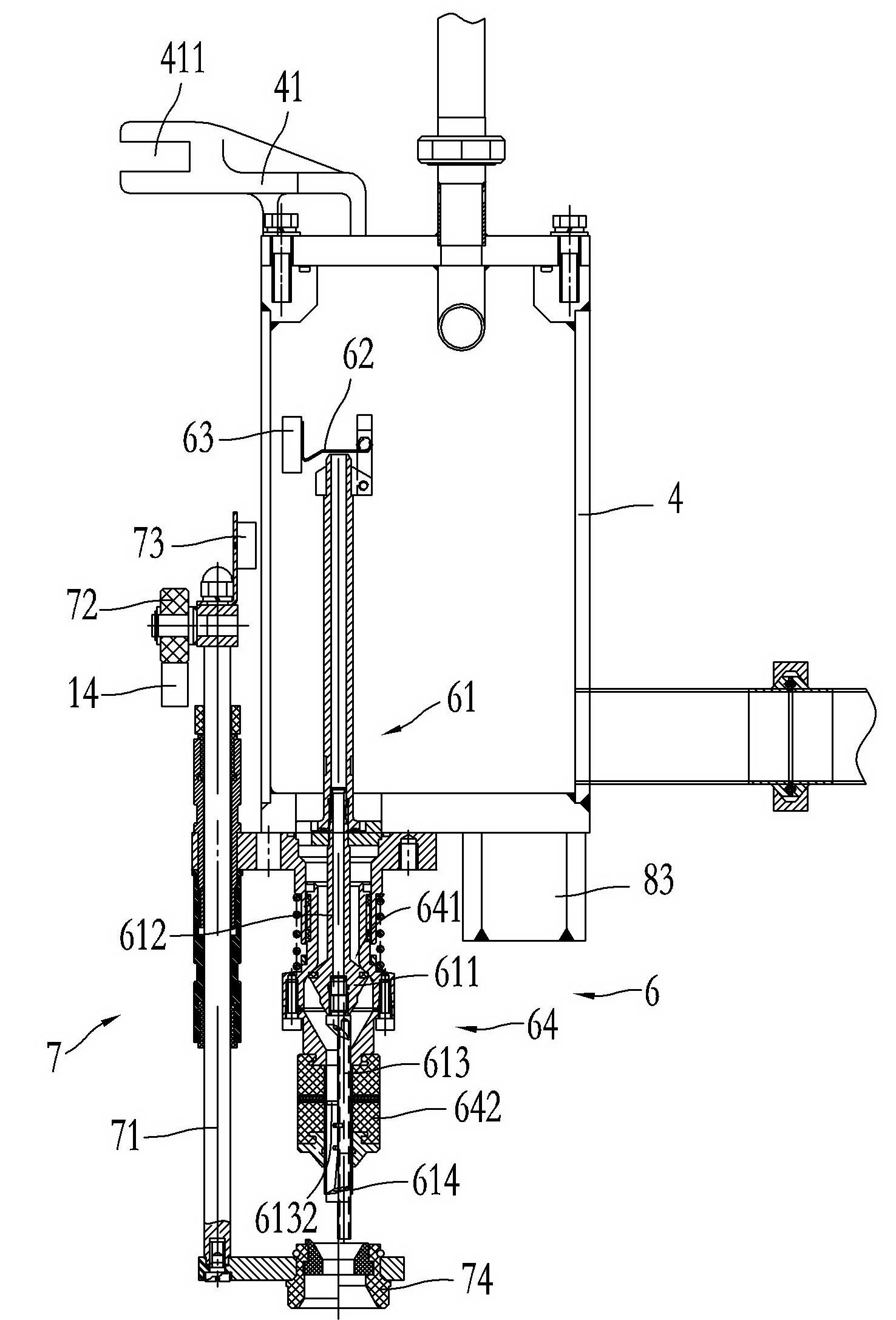

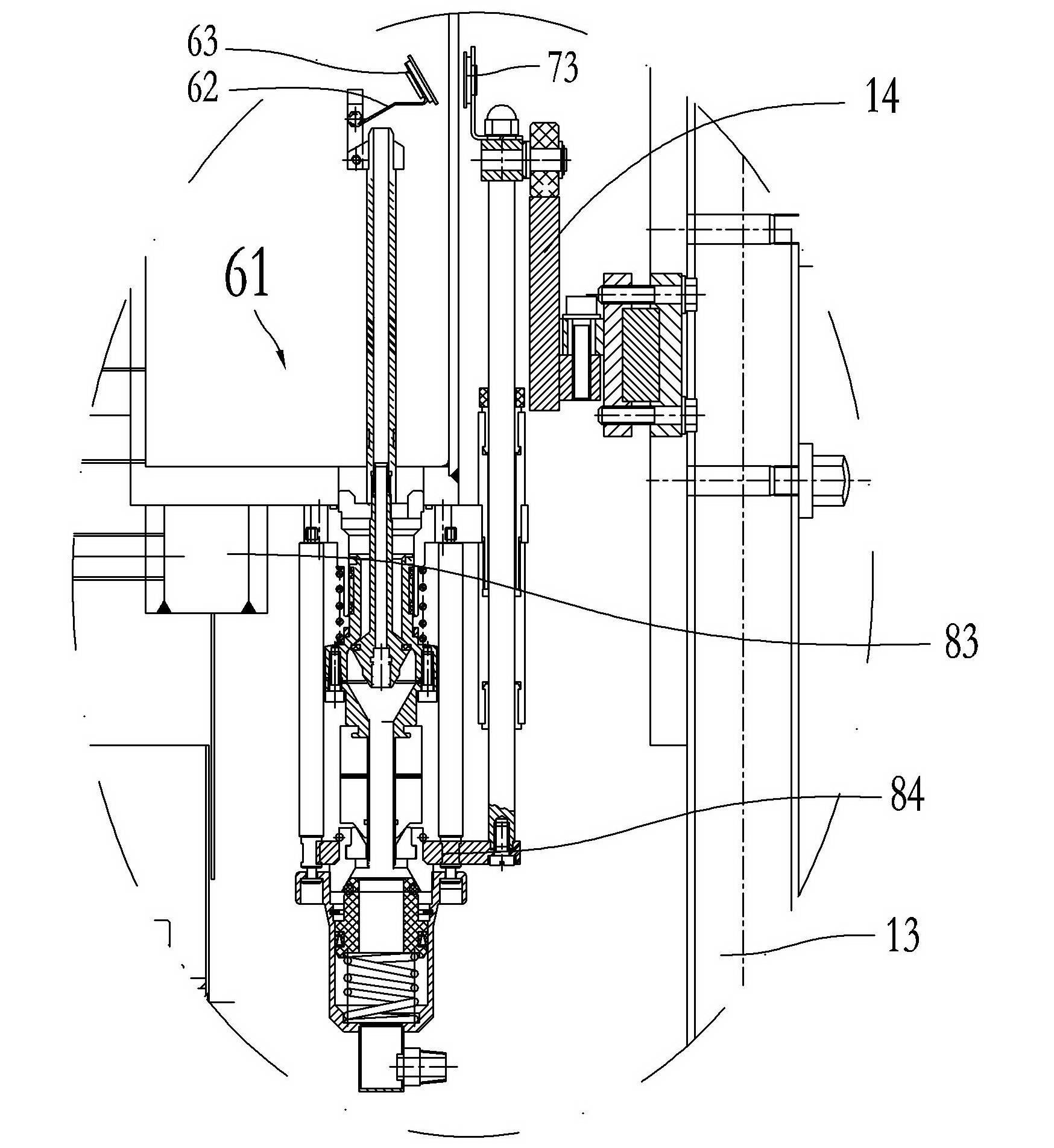

[0014] Such as Figures 1 to 3 As shown, a soy sauce filling machine according to the present invention includes a main machine and an external vacuum system. The main machine is divided into a fixed part and a rotating part. The fixed part includes a base 1, a second reduction motor 11, a guide rail device 12, and a Material pipeline 21 etc., rotating part comprises rotating platform 3, and all parts installed on rotating platform 3.

[0015] The rotating platform 3 is installed on the base 1 and can rotate relative to the base 1 under the drive of the second reduction motor. A standpipe is installed on the inner side of the corresponding rotating platform 3 on the base 1. The bottle holding device 31, the bottle holding device 31 cooperates with the guide rail device 12 fixed on the base 1, the bottle holding cylinder of the bottle holding device 31 rises when the compressed air is fed into it, so as to bring the bottle above it up, when the bottle holding device 31 When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com