Precision assemble calibrating lifting device

A lifting device and calibration technology, applied in the direction of lifting devices, lifting frames, etc., can solve the problems of lack of adjustability in positioning, inconvenient use and maintenance, etc., achieve high positioning accuracy, avoid the use of hydraulic drive devices, and ensure continuous movement Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

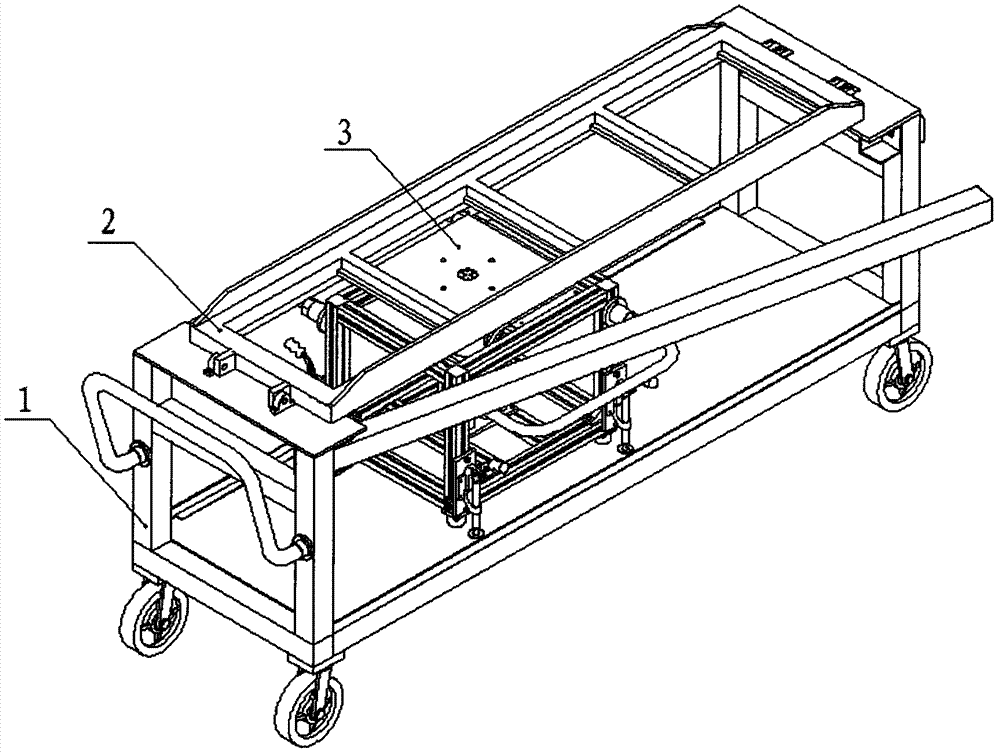

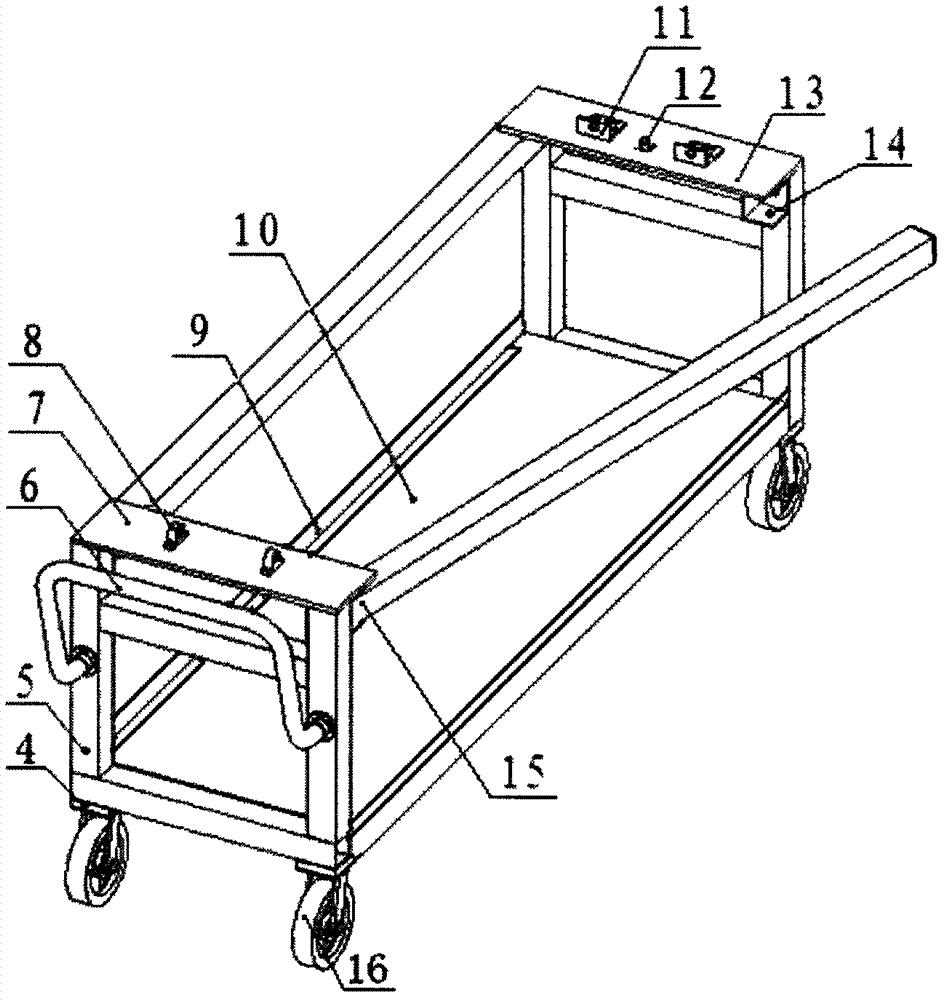

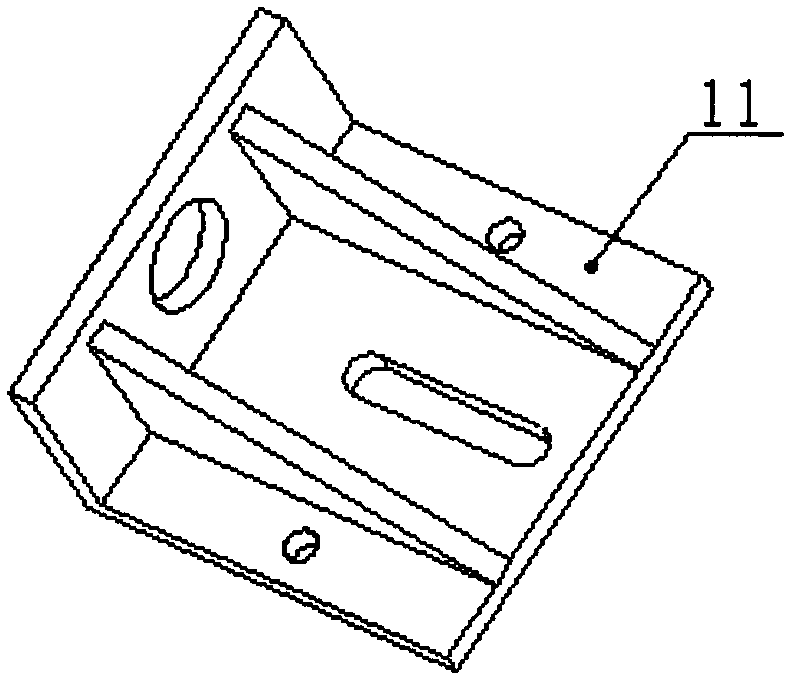

[0030] This embodiment is a precision calibration lifting device, which includes a mobile base 1, an end mirror frame 2, and a mobile lifting mechanism 3.

[0031] like figure 1As shown, the mobile base 1 is the support and coarse positioning carrier of the whole mechanism. The end mirror frame 2 is installed above the mobile base 1 and fixed on the front positioning plate 13 and the rear positioning plate 7 of the mobile base 1. The mobile lifting mechanism 3 is placed on the On the base plate 10 in the mobile base; the movable beam mechanism 15 is installed and fixed on the push handle 6 side of the mobile base 1, and the movable beam mechanism 15 can rotate outwards, and the mobile lifting mechanism 3 is placed on the base plate in the mobile base 1; fixed Move the base 1 to the station and lock the casters 16, adjust the initial station of the mobile lifting mechanism 3 so that it is below the first calibration position of the end mirror frame 2, position the mobile liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com