Control method for preventing hook from slipping when electric hoist stops

A technology of electric hoist and control method, which is applied in the direction of spring mechanism, hoisting device, etc., which can solve the problems of safety, reduce the accuracy of heavy objects, and hinder the brake action of the brake, so as to improve the accuracy and prevent the hook from slipping Phenomenon, the effect of improving the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

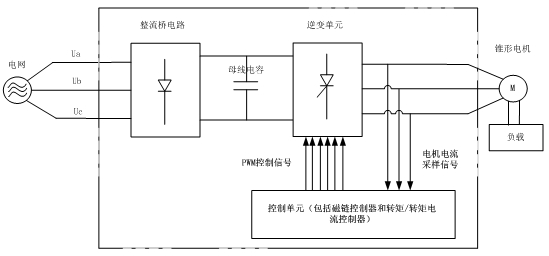

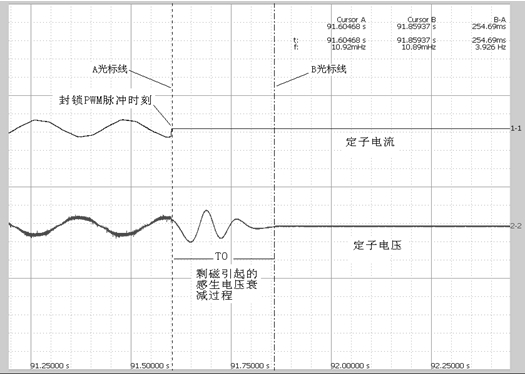

[0018] The electric hoist control structure of the present invention is as figure 1 As shown, the electric hoist is driven by a conical motor, and the control system of the conical motor includes a frequency converter with an inverter unit and a control unit (the part in the dotted line box in the figure), and the control unit includes a flux controller and a torque / torque current controller; the conical motor includes an electromagnetic brake device. The grid power is connected to the frequency converter, and the inverter control unit gives PWM pulse signals to control the inverter unit of the frequency converter to turn on and off, and the control voltage output by the inverter unit of the frequency converter controls the power supply voltage of the cone motor electric hoist. The frequency converter should realize the power-off control of the conical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com