Spiral kneading type pea huller

A peeling machine, pea technology, applied in the application, food processing, food science and other directions, can solve problems such as unfavorable equipment manufacturing and installation, and achieve the effects of high production efficiency, good peeling effect, simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

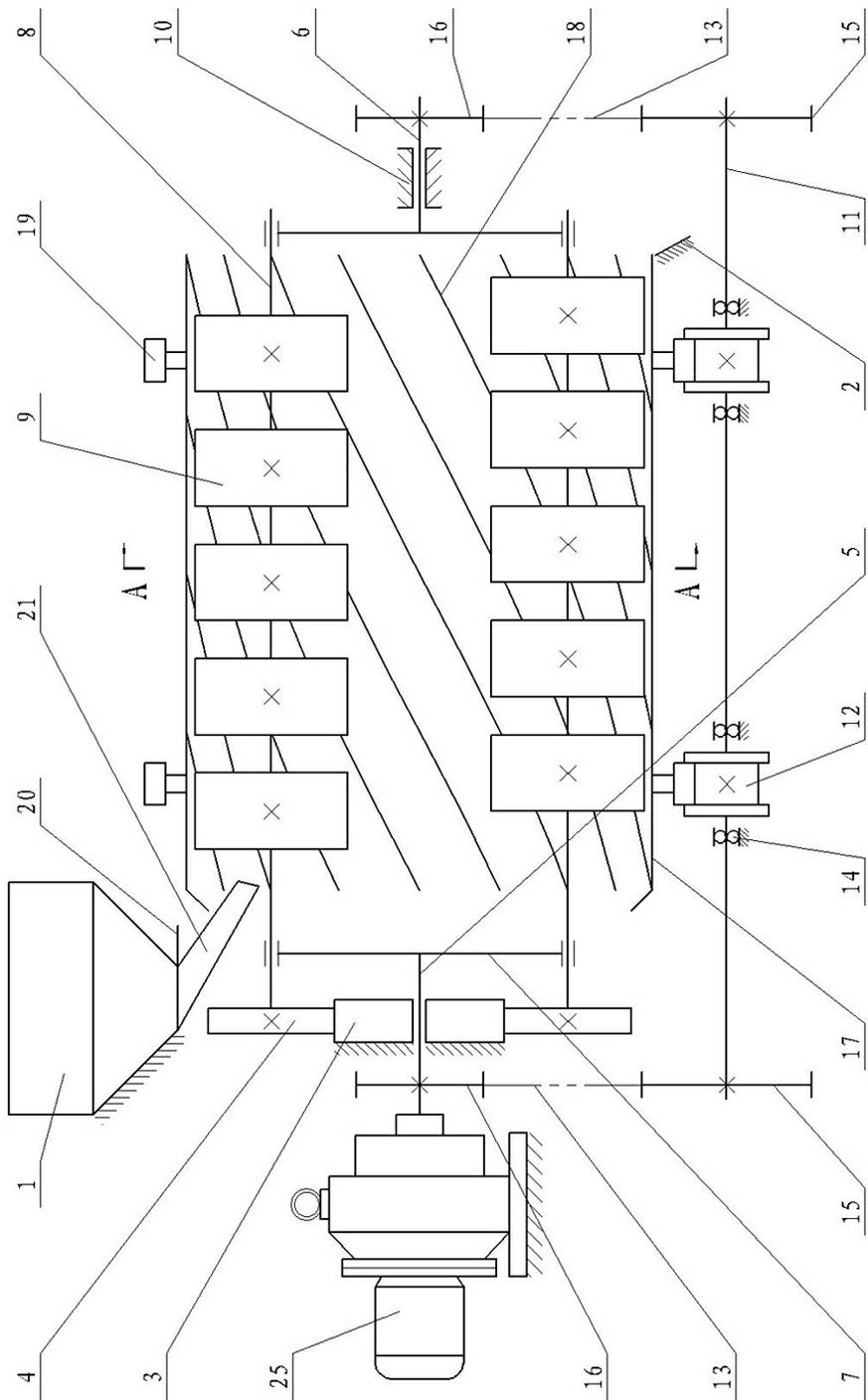

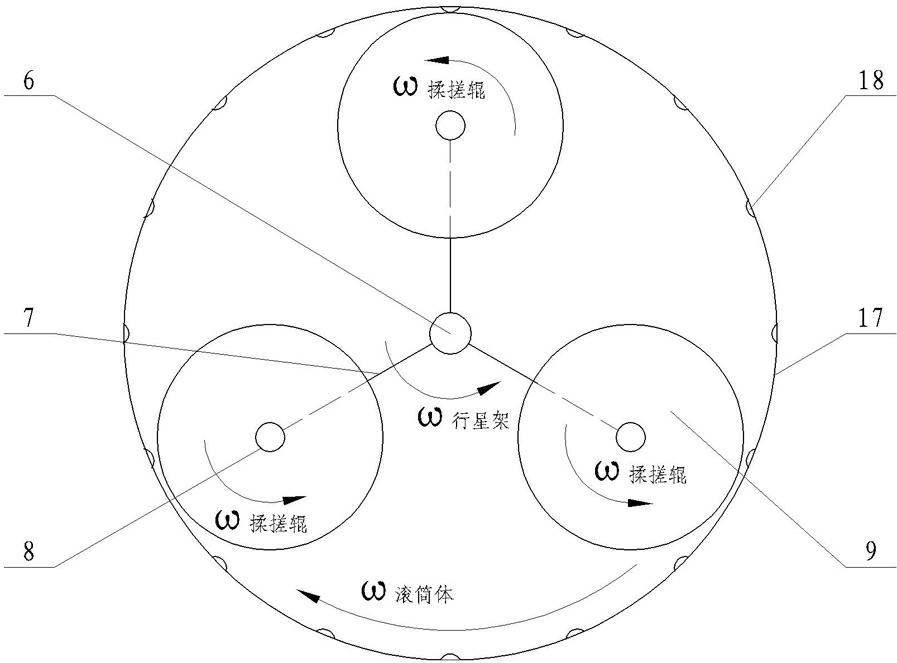

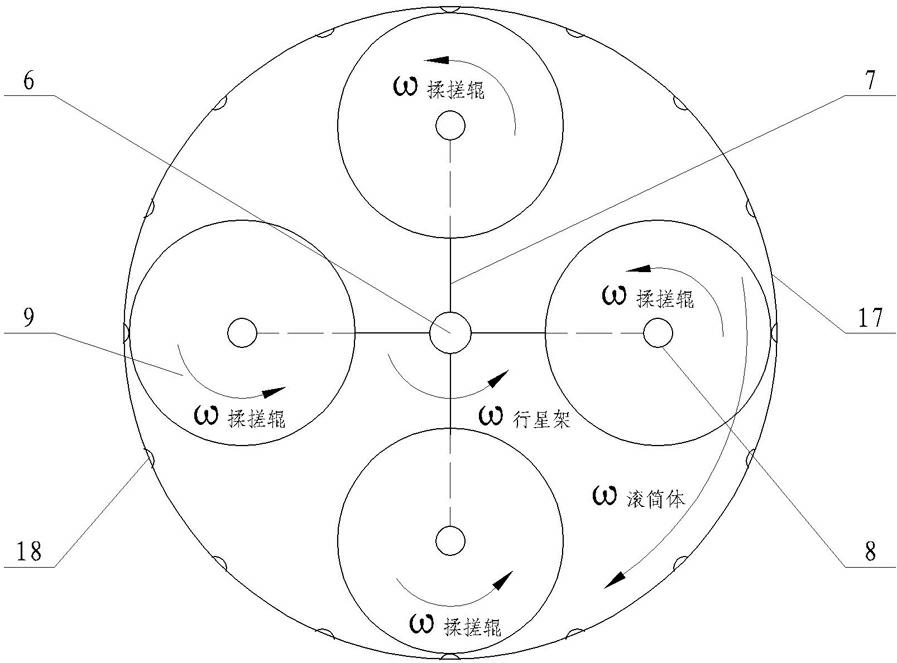

[0026] 1. Feeding hopper 2, discharge port 3, sun gear 4, planetary gear 5, driving shaft 6, driven shaft 7, planet carrier 8, planetary shaft 9, kneading roller 10, bearing Ⅰ 11, transmission shaft 12, support Roller 13, chain 14, bearing Ⅱ 15, sprocket Ⅰ 16, sprocket Ⅱ 17, drum body 18, rib 19, roller 20, feed gate 21, material guide groove 22, bolt 23, washer 24, elastic kneading claw 25, reduction motor 26, motor 27, belt transmission mechanism 28, speed reducer.

[0027] exist figure 1 , 2 , In the embodiment shown in 4 and 6: the empty sleeve in the middle of the drive shaft 5 of the planetary transmission is supported in the center hole of the fixed sun gear 3, and the middle of the driven shaft 6 is supported in the bearing I10 whose axis is coaxial with the drive shaft 5 In the hole, the common axis of the driving shaft 5 and the driven shaft 6 is parallel to the horizontal plane, and the outer end of the driving shaft 5 away from the driven shaft 6 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com