Mobile work machine having support booms

A technology of working machine and cantilever arm, which is applied in the field of drivable working machine with supporting cantilever arm, and can solve the problem that the middle position of the supporting equipment is not allowed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

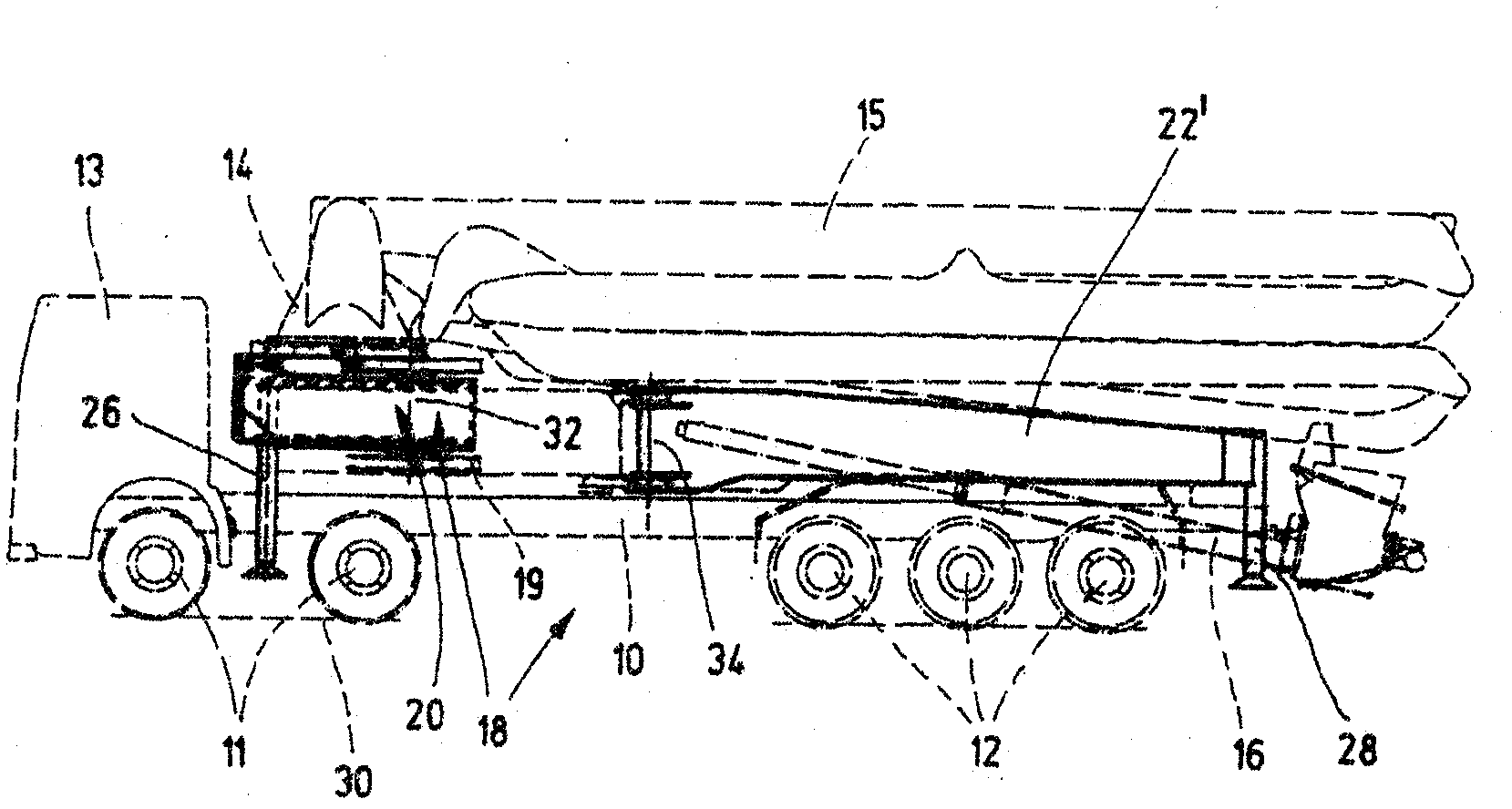

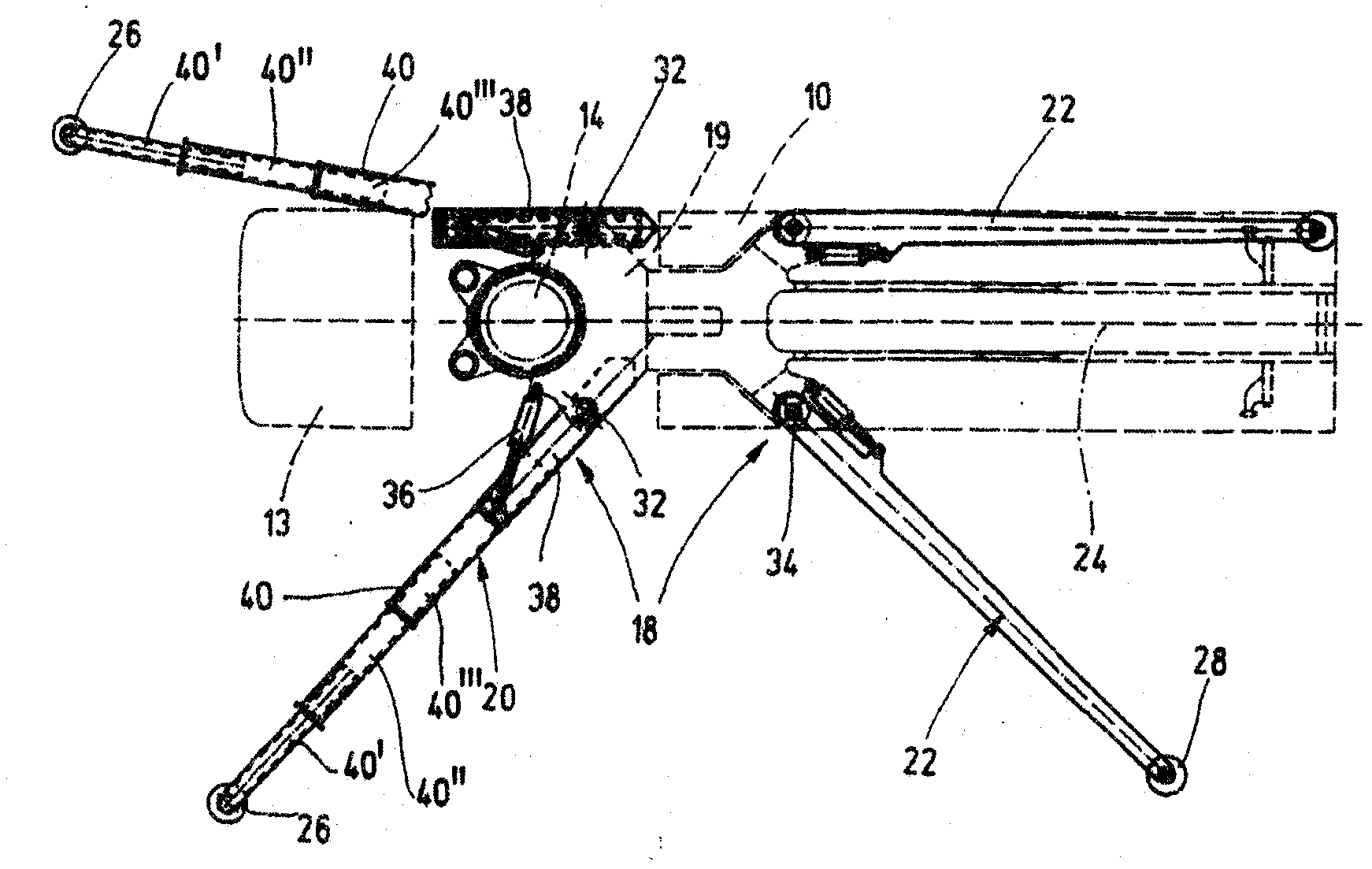

[0017] exist Figure 1a The concrete pump truck shown in b and b mainly includes a multi-axle chassis 10 with two front axles 11 and three rear axles 12 and a driver's cab 13, a rotating mechanism that is rotatably supported around a vertical axis near the front axle The concrete placing boom 15 on 14 has a pump unit 16 mounted on the chassis 10 at a distance from the swivel mechanism 14 and a support structure 18 for the chassis 10. The support structure 18 has a support frame 19 fixed to the chassis and comprises two front support suspension arms 20 and two rear support suspension arms 22 which are folded in the transport position and parallel to the longitudinal axis 24 of the vehicle. Oriented so that the chassis 10 protrudes obliquely forwards or rearwards in the bearing position.

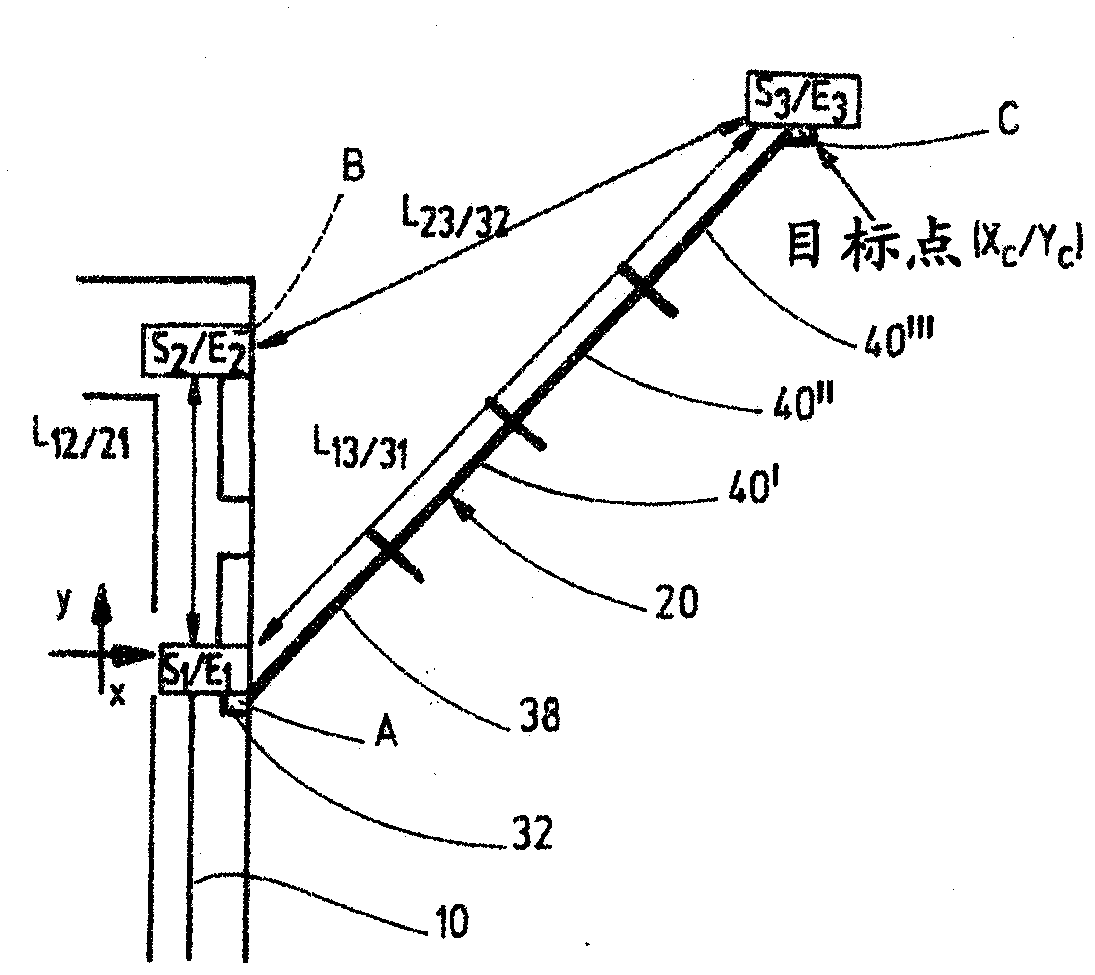

[0018] Under the action of the adjusting cylinders 36, the front support arm 20 is pivotable about its vertical pivot axis 32 and the rear support arm 22 about its vertical pivot axis 34 betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com