Rotary motive seal type microwave leakage prevention device

A rotary sealing and microwave technology, applied in microwave heating, drying solid materials, lighting and heating equipment, etc., can solve the problems of inability to completely seal, difficult to effectively prevent microwave leakage, etc., to control the amount of microwave leakage, prevent microwave leakage, and improve the protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

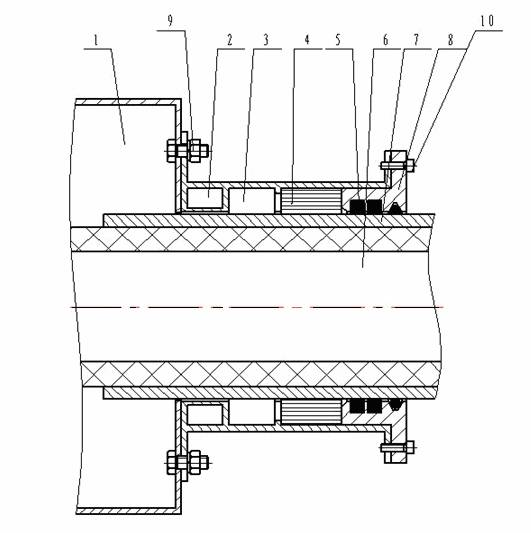

[0011] Such as figure 1 As shown, a rotary dynamic seal type microwave leakage prevention device includes a microwave source cavity 1 mounted on a frame, a rotatable material conveying roller 6 passing through the middle of the microwave source cavity, and the material conveying roller 6 passes through The sleeve 7 sleeved on its outer surface is installed in cooperation with the microwave source cavity 1 . Outside the sleeve 7, it is located at both ends of the microwave source cavity, and along the axial direction of the drum, an annular reactive leak composed of a combination of a cut-off waveguide leakage energy suppressor 2 and a 1 / 4 waveguide groove suppressor 3 is installed sequentially from the inside to the outside. An energy suppressor, an annular resistive energy leakage suppressor composed of a wave-absorbing filler ring 4 and a wave-absorbing sealing ring 5; one side of the annular reactive energy leakage suppressor and the outer end side plate of the microwave so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com