Novel tensioning transmission device

A transmission device and tensioning device technology, which is applied in the field of new tensioning transmission devices, can solve the problems of chain disconnection, loss of function, easy stretching and lengthening, etc., and achieves the improvement of work efficiency, improvement of cleaning effect, and reduction of friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

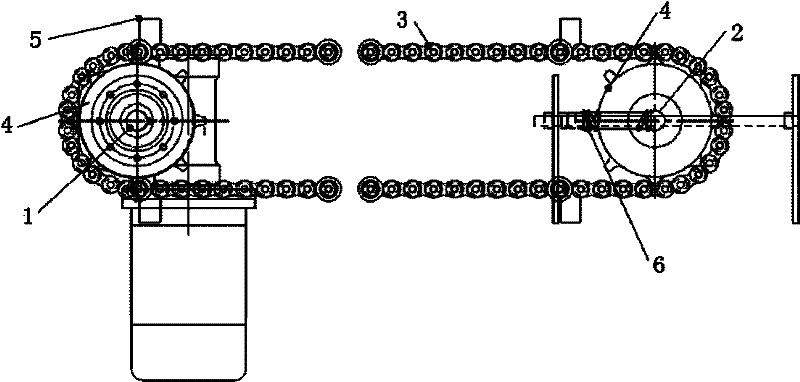

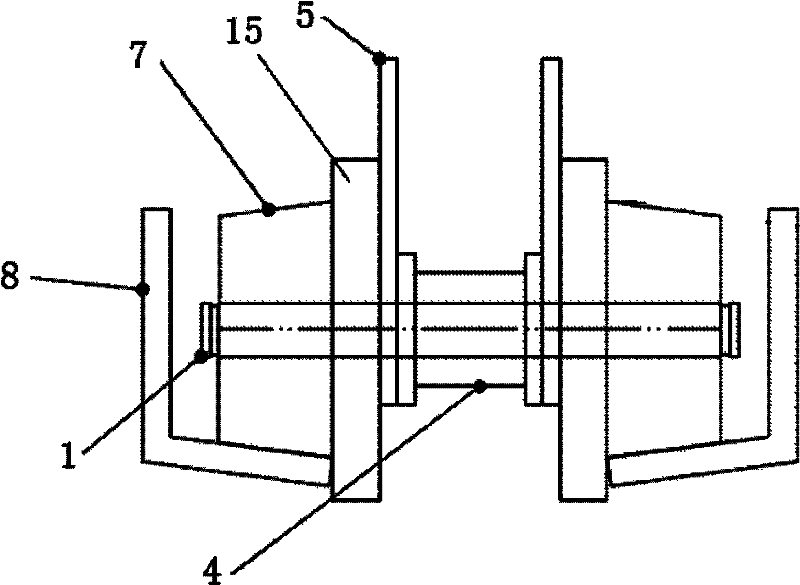

[0016] Such as figure 1 , 2 As shown, a novel tension transmission device of the present invention comprises a chain 3, a guide rail 8, a driving shaft 1 and a driven shaft 2 driven by a driving device, and the middle of the driving shaft 1 and the driven shaft 2 are respectively fixed with Sprocket 4, the two ends are fixed with the guide wheel 7 that matches with described guide rail 8, between described sprocket 4 and guide wheel 7, be fixed with push box finger 5, described driven shaft 2 is provided with spring tensioner. Tightening device 6.

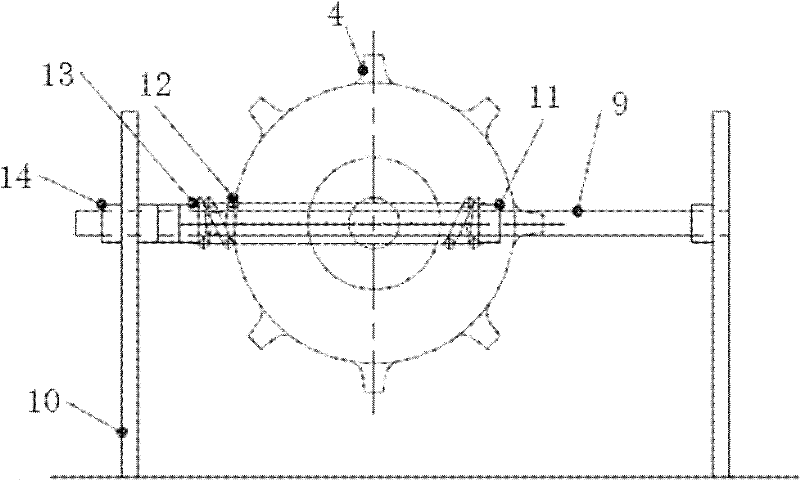

[0017] Such as figure 1 , 3 4. The spring tensioning device 6 shown in 4 includes two fixing plates 10, two lead screws 9 fixed in the middle of the fixing plates 10, and the lead screws 9 pass through the end of the driven shaft 2; Located at one end of the driven shaft 2, a fixed nut 11 mounted on the lead screw 9, located at the other end of the driven shaft 2, a compression spring 12 mounted on the lead screw 9, the compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com