High-speed main shaft with controllable non-uniformly distributed pre-tightening force and control method thereof based on regulation and control of hydraulic system

A non-uniform distribution, hydraulic system technology, applied in the direction of manufacturing tools, large fixed members, metal processing machinery parts, etc., can solve the problem of not being able to effectively eliminate the non-uniform distribution of axial and radial clearance, and not satisfying the non-uniformity of the working load. Uniform distribution requirements and other issues to achieve the effect of low temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

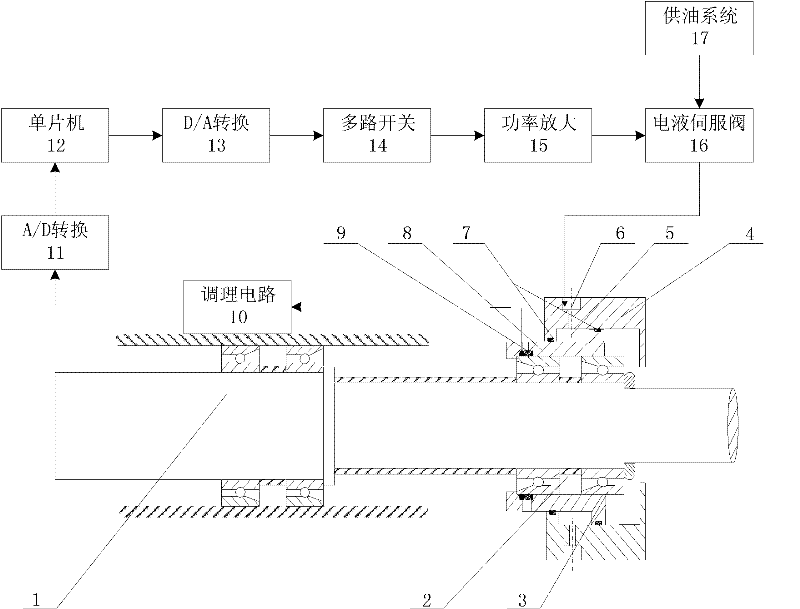

[0016] The following is a specific introduction to the non-uniformly distributed preload controllable high-speed spindle and its control method based on the hydraulic system regulation of the present invention in conjunction with the accompanying drawings:

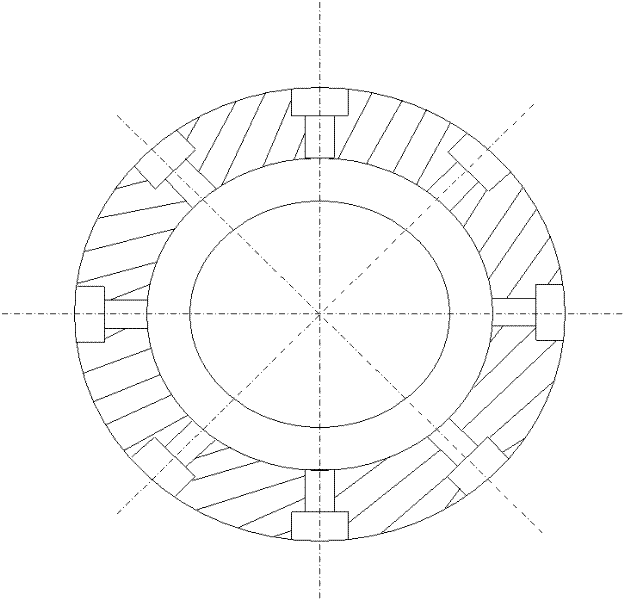

[0017] see figure 1 As shown, the present invention is based on the controllable non-uniform distribution pretightening force of the hydraulic system. The high-speed main shaft includes a main shaft 1, a rolling bearing 3 is installed on the outer periphery of the main shaft 1, and a sleeve 2 is installed on the surface of the outer ring of the main shaft between a pair of rolling bearings 3; The rolling bearing 3 located at the front end of the main shaft 1 is equipped with a hydraulic control pretightening force system, and the hydraulic control pretightening force system is regulated by a control device.

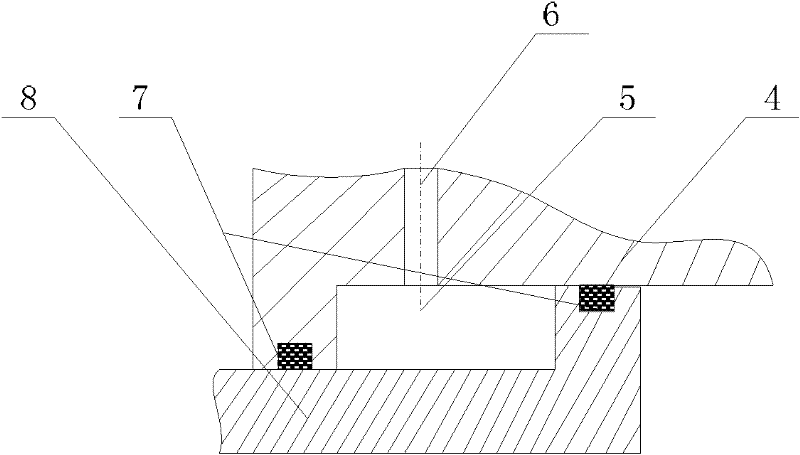

[0018] The hydraulic control pretightening force system includes a hydraulic actuator sleeve 8 acting on the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com