Water tank cover lifting device of turnover water tank wire drawing machine

A water tank wire drawing machine and water tank cover technology, which is applied in the field of wire drawing machines, can solve the problems of low work efficiency and inconvenient operation, and achieve the effects of simple structure, reduced work intensity and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific drawings and embodiments.

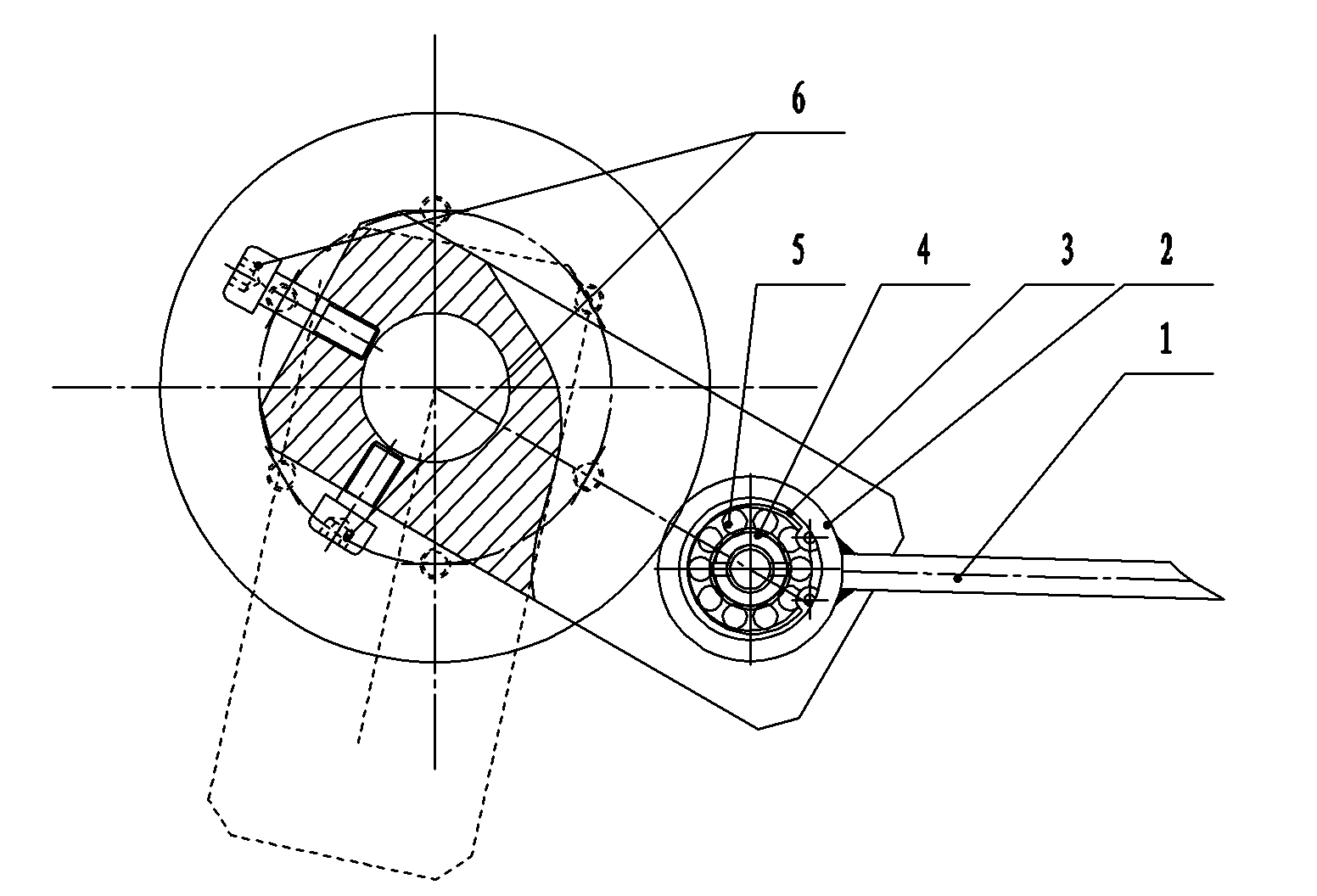

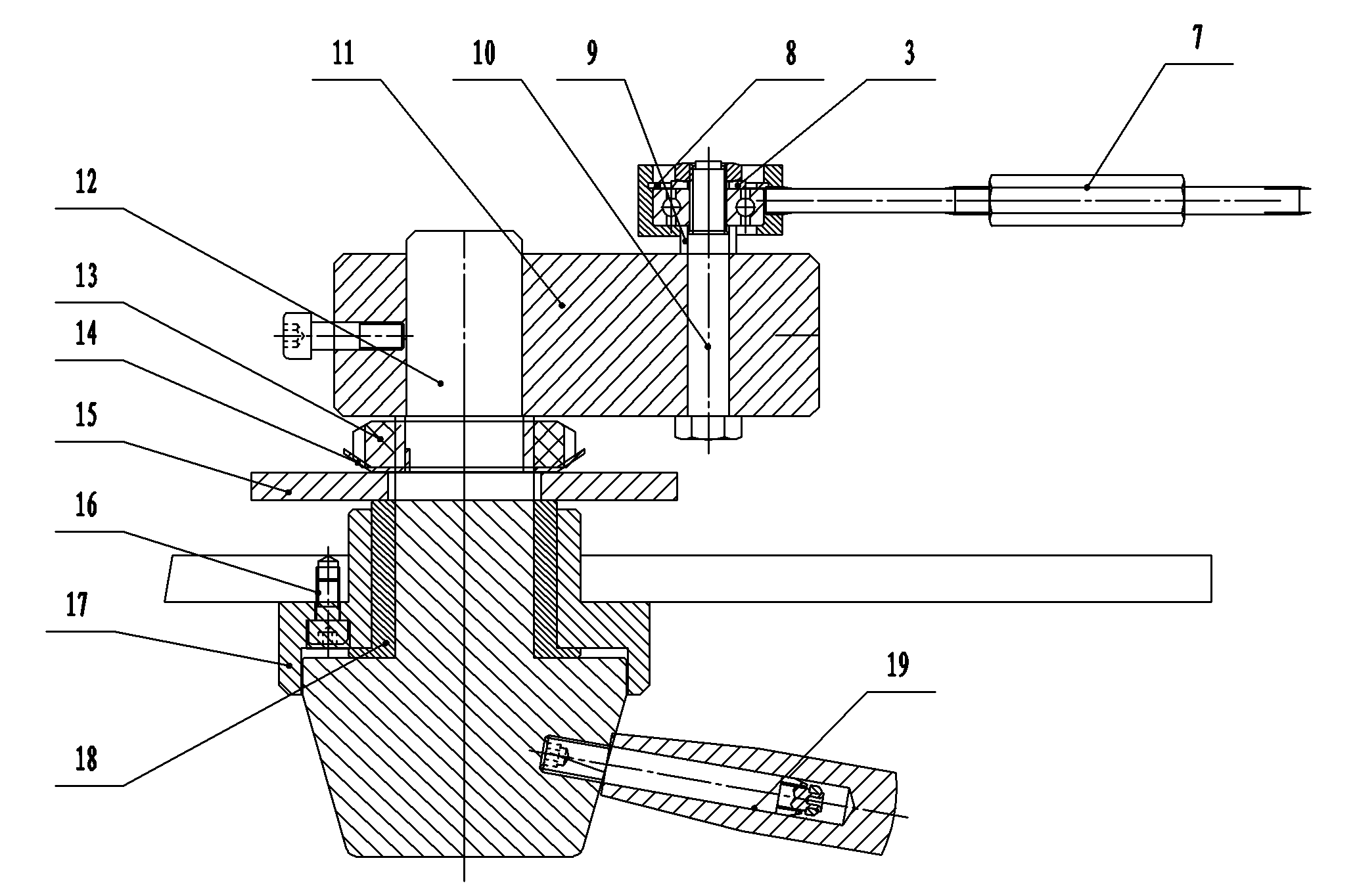

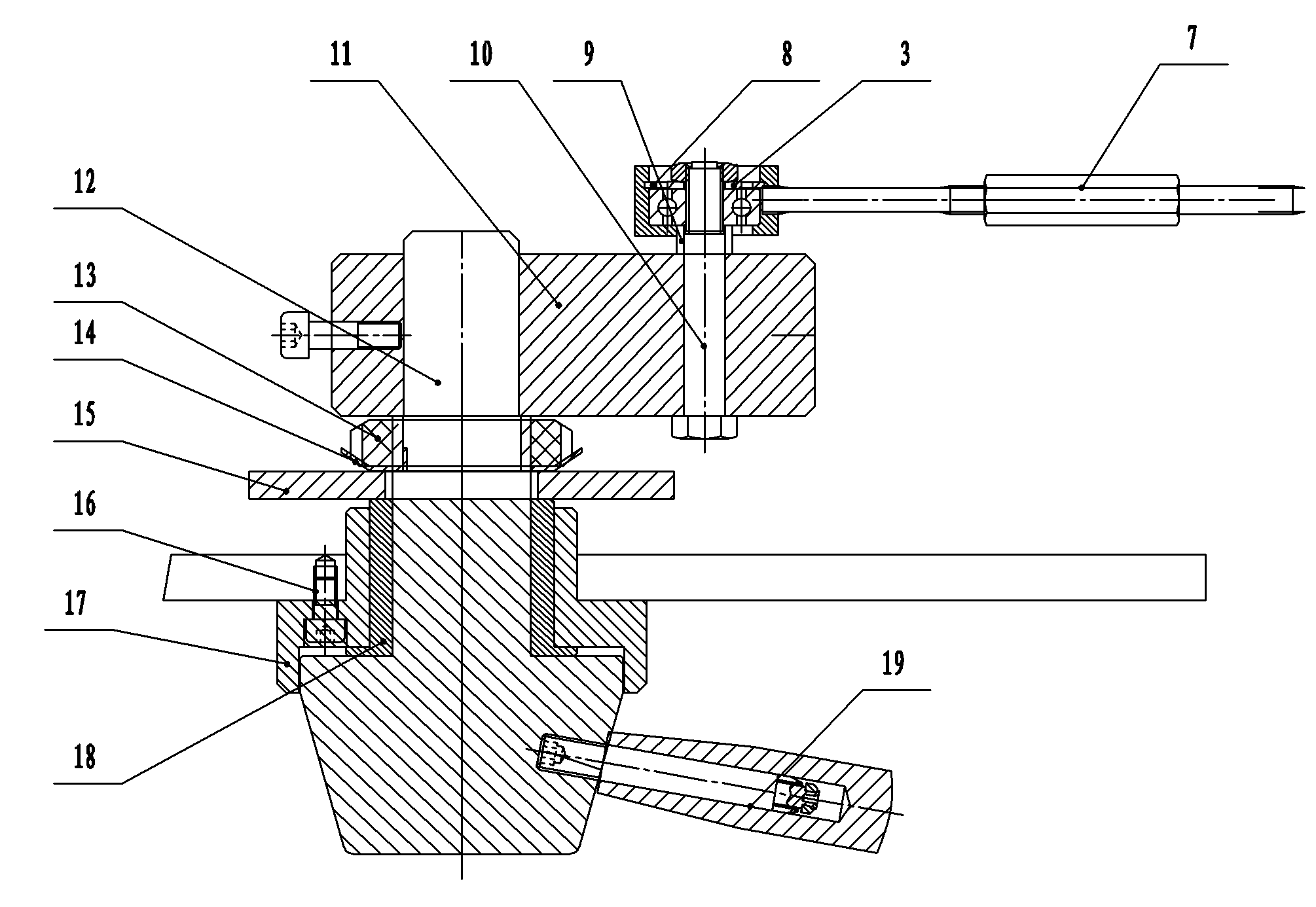

[0014] As shown in the figure, the water tank cover lifting device of the flip-type water tank wire drawing machine is mainly composed of a pull rod 1, a rotating shaft seat 2, a circlip 3 for a hole, a nut 4, a bearing 5, a set screw 6, an adjusting sleeve 7, a pad Sheet 8, support sleeve 9, bolt 10, lifting plate 11, rotating shaft 12, round nut 13, stop washer 14, large washer 15, hexagon socket cap screw 16, rotating shaft seat 17, shaft sleeve 18 and rotating handle 19 and other parts components.

[0015] like figure 1 , figure 2 As shown, the rotating shaft seat 17 is fixedly installed on the water tank body by using hexagon socket head cap screws 16, and the rotating shaft 12 is rotatably installed in the rotating shaft seat 17 through the axle sleeve 18; the front end of the rotating shaft 12 is equipped with a rotating handle 19 , turning the handl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com